Liquid distributor, heat exchanger and air conditioner

A liquid distributor and heat exchanger technology, which is applied in the field of air conditioning, can solve the problems of dry spots of heat exchange tubes, uneven liquid film formation, etc., and achieve the effects of improving heat exchange efficiency, increasing contact area, and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

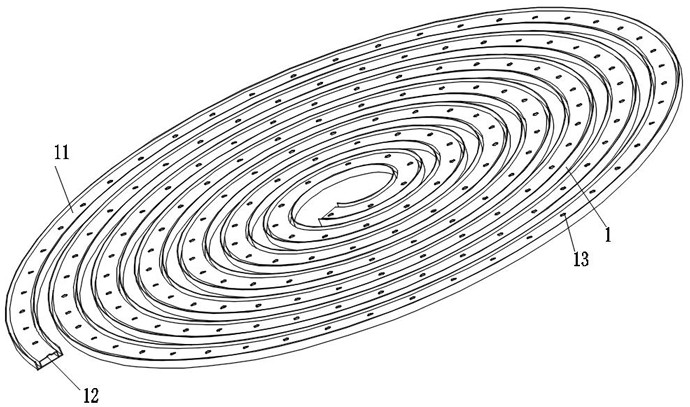

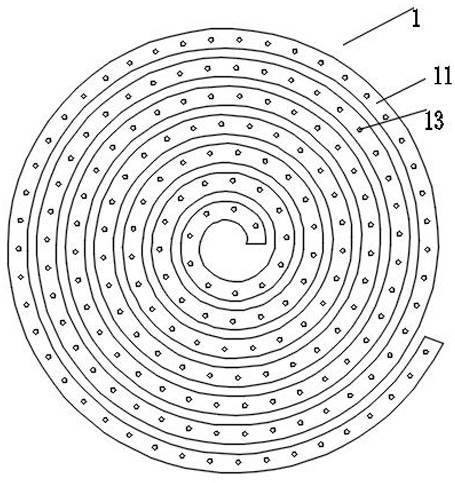

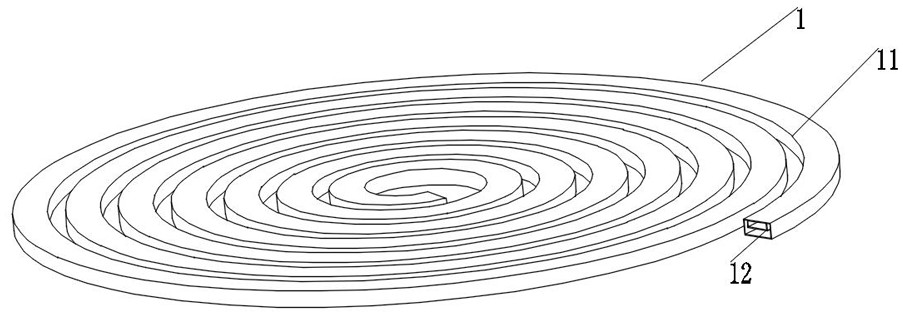

[0036] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] The principle and structure of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0038] With the progress of society, people's living demands are constantly improving and upgrading. In the past, due to the limitation of the level of science and technology, people only required the heat exchanger to have the heat exchange function, and did not take into account the shape, size, efficiency, energy consumption and other factors of the heat exchanger. However, with the continuous development of society, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com