Battery cell of cylindrical lithium ion power battery, and processing method thereof

A power battery and lithium-ion technology, which is applied in the cell and processing field of lithium-ion cylindrical power batteries, can solve the problem that the edge of the negative electrode dressing is easily lower than the edge of the positive electrode dressing, the deformation stress cannot be released, and the edge of the dressing is damaged without considering the winding fluctuation. In order to avoid the problem of poor coating, solve the problem of wrinkle and lithium deposition, and relieve the release of deformation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

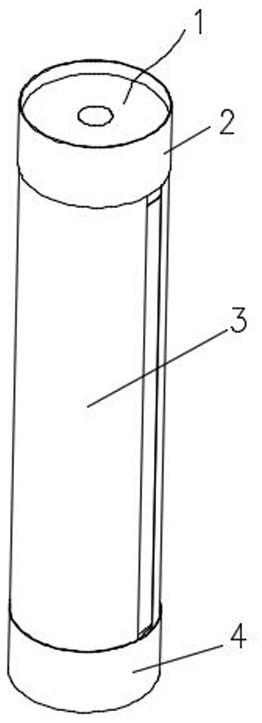

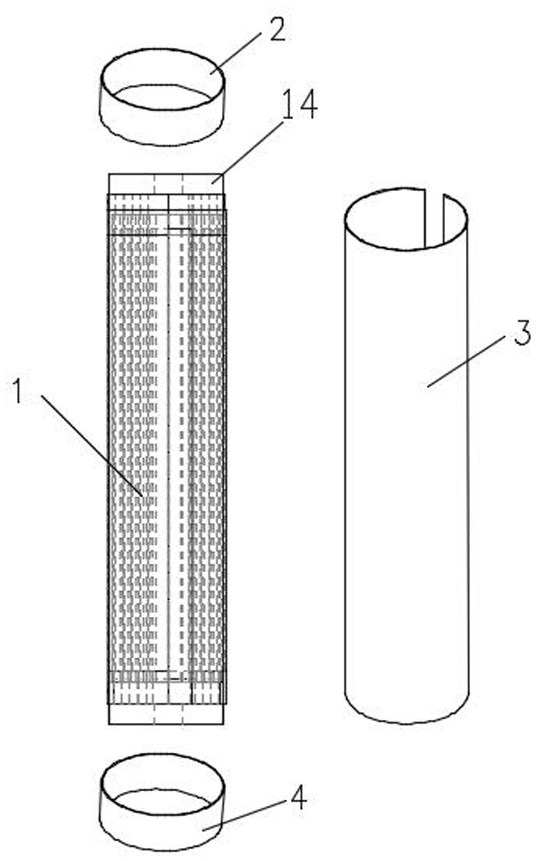

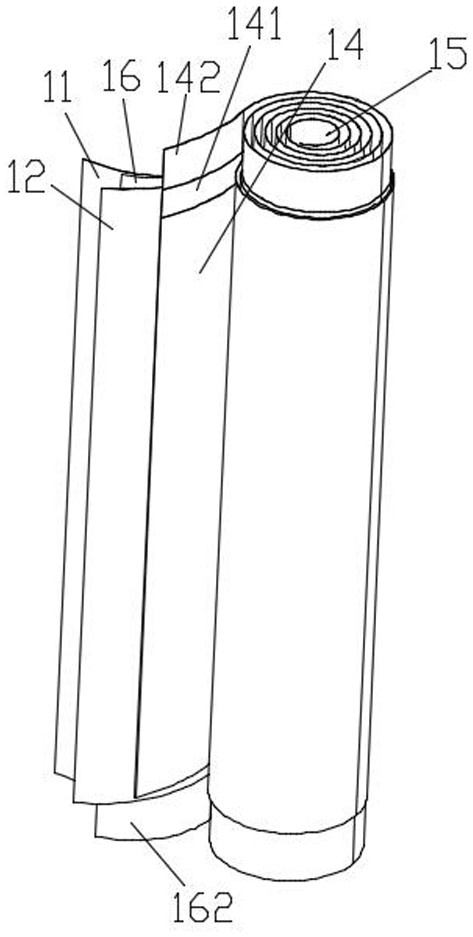

[0030] like Figure 1 to Figure 5 As shown, the present invention includes: a battery core 1, the battery core includes a positive electrode sheet 14, a negative electrode sheet 16, a diaphragm one 11, a diaphragm two 12, a C-type glue 3, a positive electrode head protective glue 2, a negative electrode head protective glue 4, a positive electrode A positive electrode dressing 141 is provided on the sheet, a negative electrode dressing 161 is provided on the negative electrode sheet, a ceramic layer 142 is provided above the positive electrode dressing on the positive electrode sheet, and a positive electrode blank foil 143 is provided above the ceramic layer to the side of the positive electrode dressing. The top of the core is flush, and the lower end of the positive electrode sheet is higher than the lower end of the negative electrode sheet; the negative electrode dressing extends to the edge of the upper end of the negative electrode sheet, and the edge position of the neg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap