Full-automatic PIN dismounting method and device

A fully automatic, mobile-related technology, applied in the direction of furniture waste recycling, solid waste removal, recycling technology, etc., can solve the problems of reducing manual transfer, complex operation and low efficiency, etc., to reduce manual transfer, improve operation efficiency, structure well-distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

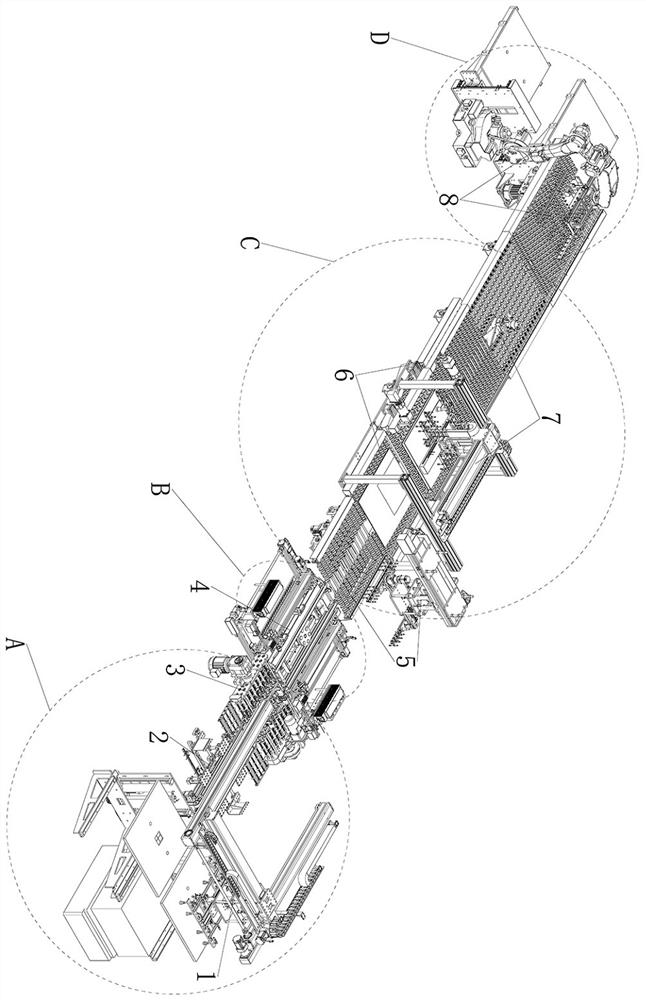

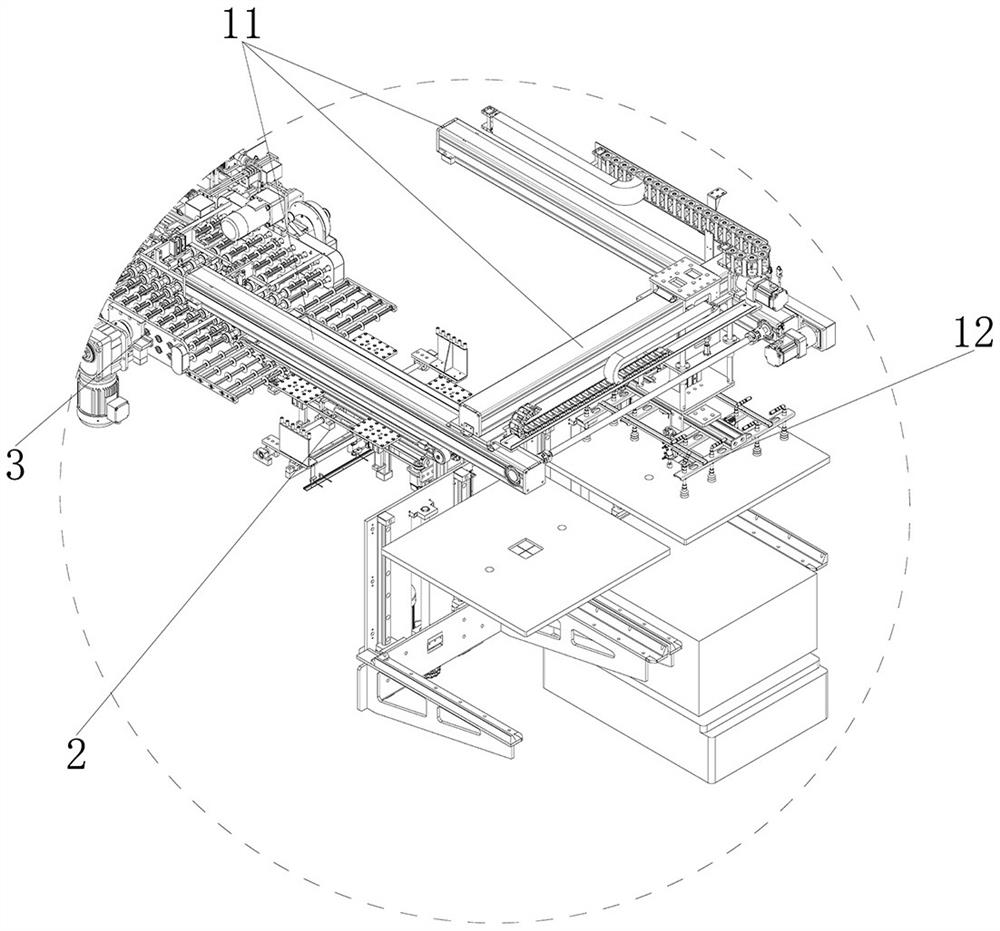

[0054] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

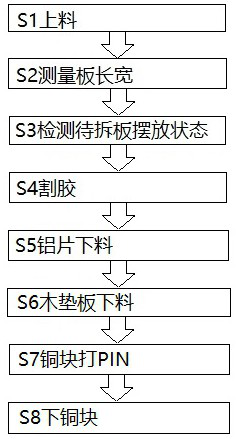

[0055] like Figure 1-6 As shown in , a fully automatic PIN removal method provided by an embodiment of the present invention includes the following steps:

[0056] S1 loading, transfer the board to be removed to the length and width parts of the measuring board;

[0057] S2 measures the length and width of the board, moves the relevant splint to clamp the board to be removed by the motor, and calculates the length and width of the board through the memory mode in the motor according to the amount of movement;

[0058] S3 detects the placement status of the board to be removed, and uses the detector to detect whether the aluminum sheet to be removed is facing up; if the aluminum sheet is facing down, turn the board to be removed 180 degrees so that the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com