Ejector, processing device, and cleaning device

A technology for injectors and cleaning objects, which is applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve problems such as increased chip manufacturing costs, reduced attractiveness of injectors, poor processing or cleaning, etc., to reduce defects Affects, inhibits the effect of reducing attractiveness, cheap processing or cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

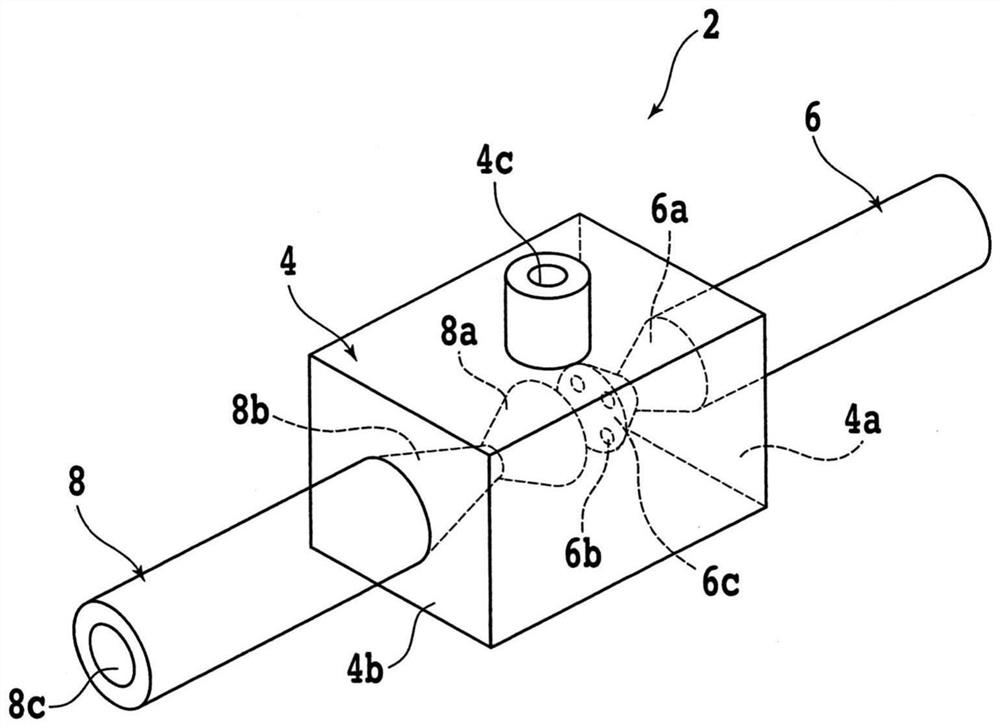

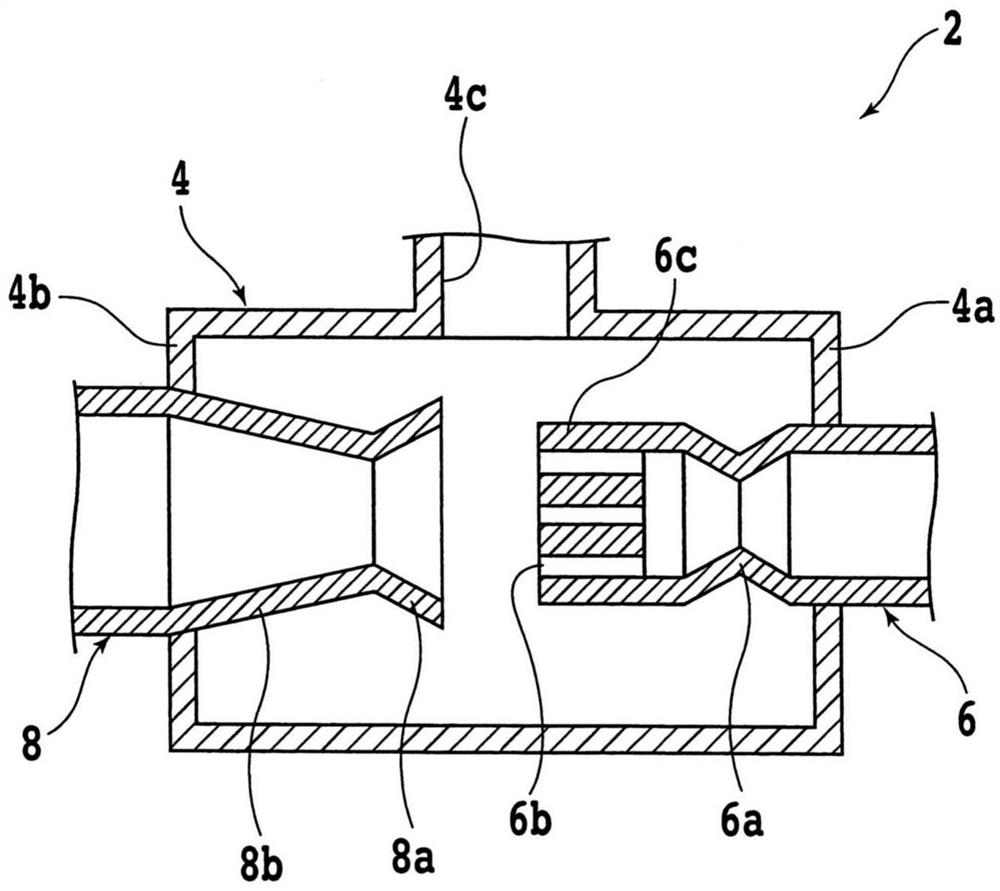

[0033] Embodiments of the injector will be described with reference to the drawings. figure 1 is a perspective view schematically showing the injector 2 of the embodiment, figure 2 is schematically shown figure 1 A cross-sectional view of a portion of injector 2 is shown.

[0034] The injector 2 generates an attractive force by causing a driving fluid to flow inside the main body portion 4 isolated from the outside. The driving fluid may be either liquid or gas. The driving fluid is, for example, a liquid such as water, or a gas such as air or an inert gas such as argon or nitrogen.

[0035] The main body part 4 has mutually opposing walls 4a and 4b, and the suction path 4c provided in the wall of the main body part 4 other than the walls 4a and 4b. Furthermore, one end side of the inflow pipe 6 is inserted into the wall 4a, and one end side of the outflow pipe 8 is inserted into the wall 4b.

[0036] The inflow pipe 6 provides a path for the driving fluid to flow into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com