Low-cost holographic anti-counterfeiting optical design and manufacturing method and platemaking device thereof

A holographic anti-counterfeiting and optical design technology, applied in the direction of printing plate preparation, printing, etc., can solve the problems of many processes, long processing time, environmental pollution, etc., and achieve the effect of solving focus matching and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to make the objects, technical solutions, and advantages of the present invention, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are merely the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are in the range protected by the present invention.

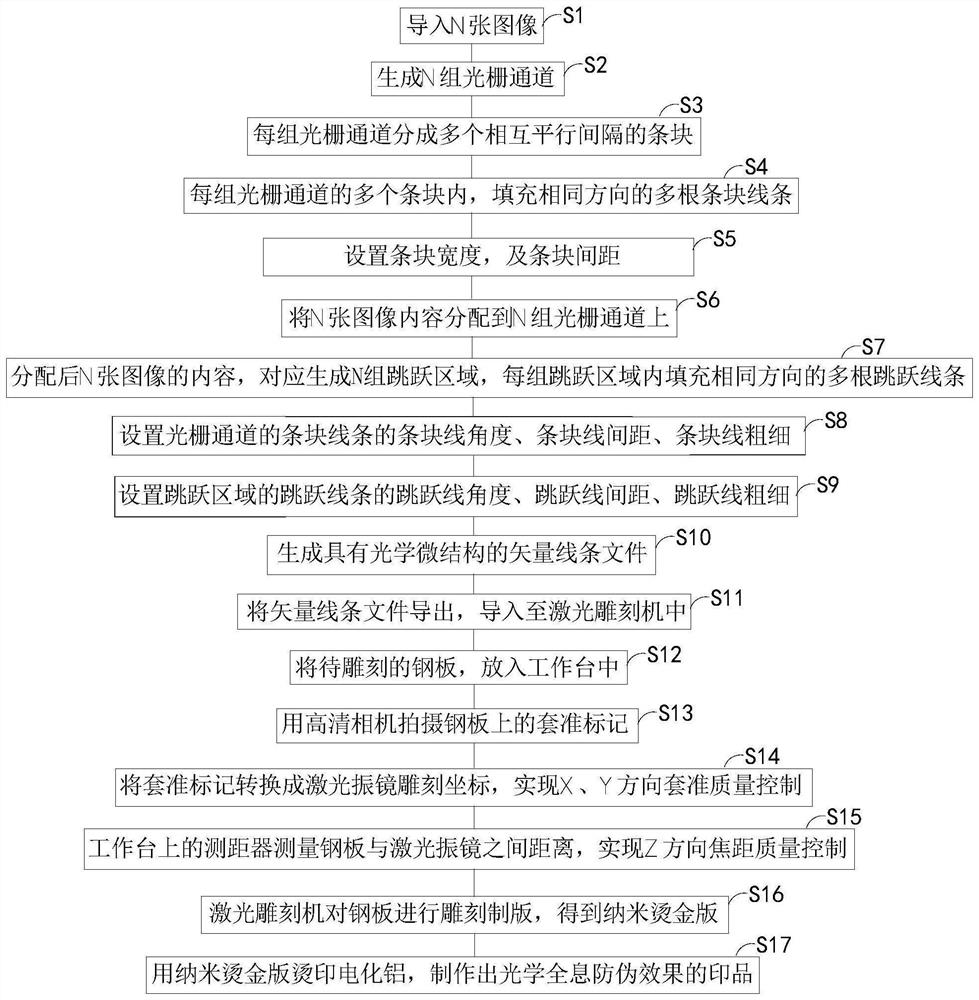

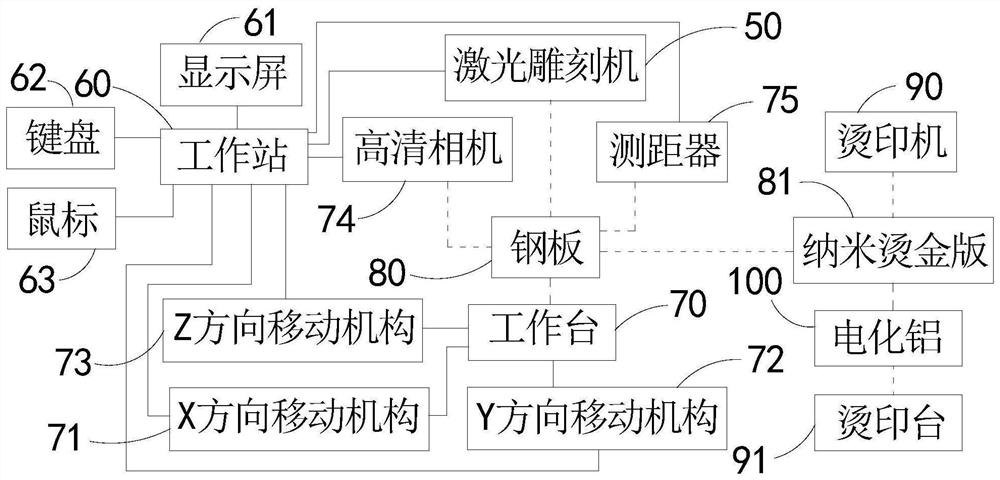

[0073] like Figure 1 to 13 , The present invention provides a low cost method of making holograms, optical design, according to the following steps:

[0074] Sl, introduced N images; (there are two such images, the first image is AB, as the second image D) (Note: the image comprises any one or combination of several words or letters or pattern.)

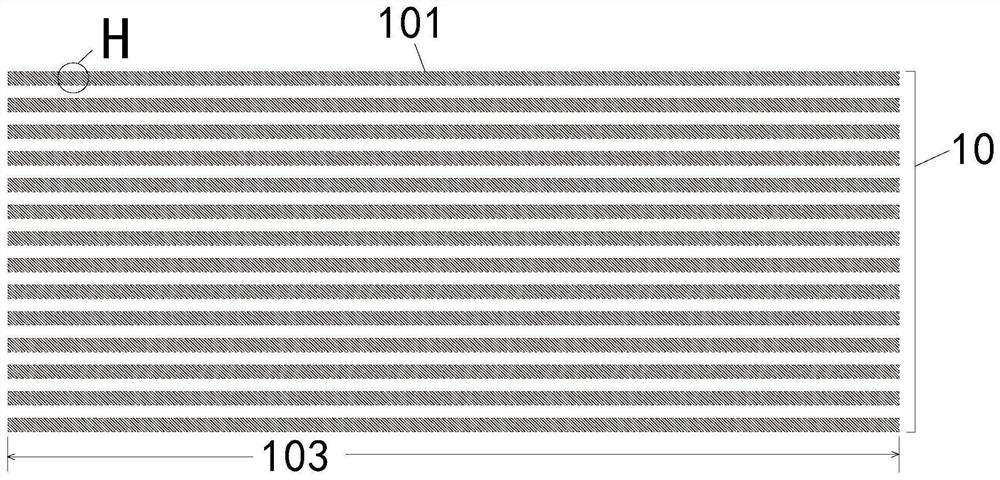

[0075] S2, generating a set of N-channel grating; (such as a 2-channel groups grating, the first grating passage 10, the second gate channel 20)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com