Cutting equipment for veneer defects

A defect and equipment technology, which is applied in the field of veneer defect removal equipment, can solve the problems of fixed incision of cutting equipment and failure to meet cutting requirements, and achieve the effects of easy operation, improved manual repair efficiency, and good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

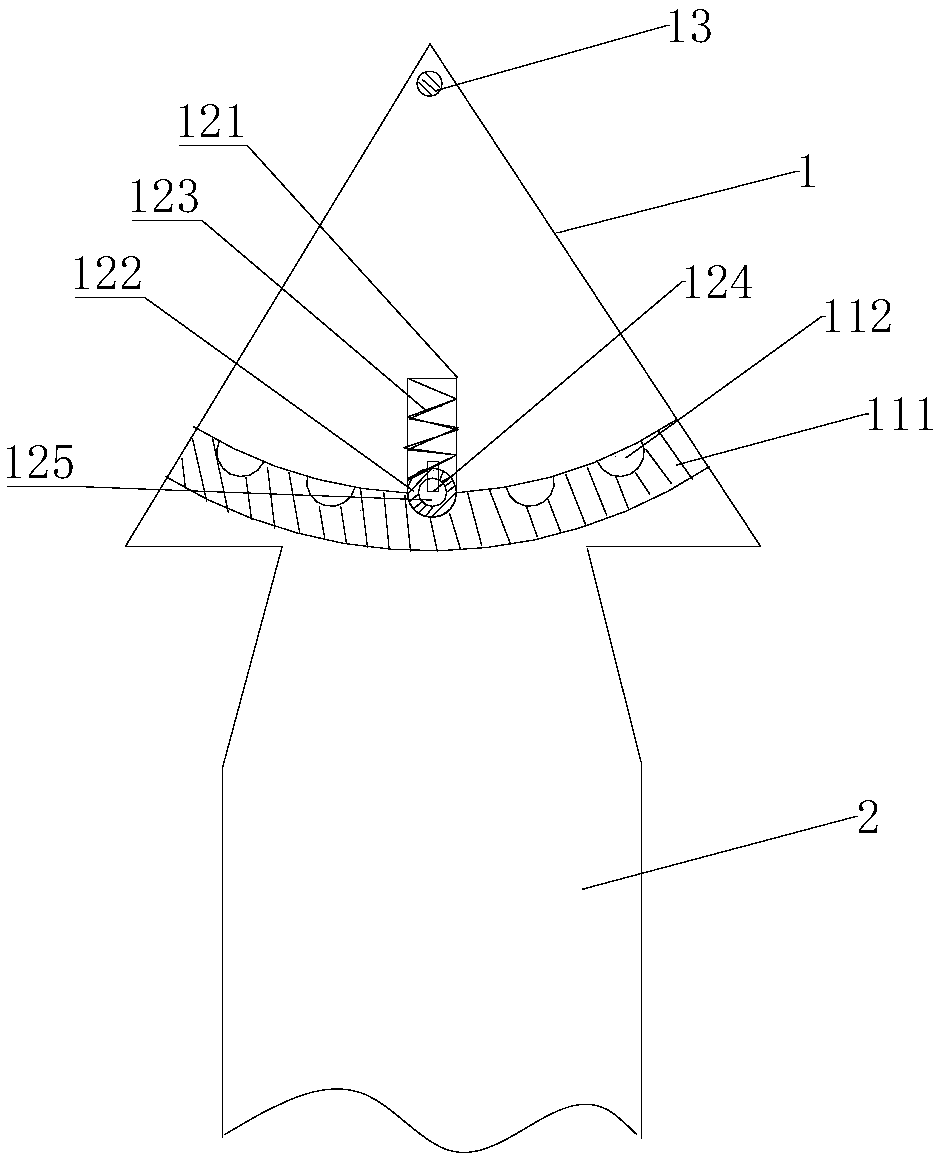

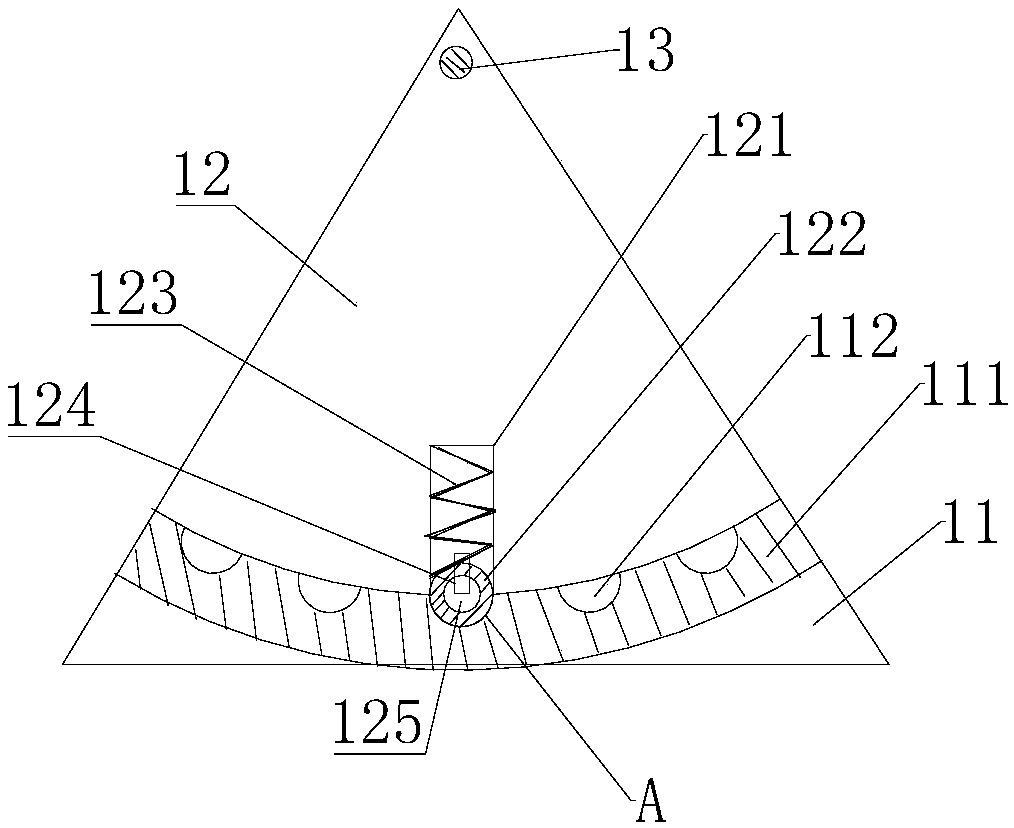

[0025] refer to Figure 1 to Figure 2 , this embodiment discloses a cutting device for veneer defects, comprising a multipurpose cutter head body 1 and a blade body 2 connected to the cutter head, the multipurpose cutter head body 1 includes a triangular part 11 and a fan-shaped part 12, wherein the The triangular part 11 is an equilateral triangle, and the central angle of the fan-shaped part 12 is 60°; the triangular part 11 and the fan-shaped part 12 are fixedly hinged by a pin 13, and the bottom edge of the triangular part 11 is welded on the blade body 2 , the remaining two sides are all set as blades; the two sides of the fan-shaped part 12 are all set as blades, and the fan-shaped part 12 can rotate freely; in order to ensure the sharpness and durability of the cutter head, the triangular part 11 and the fan-shaped part 12 The vertical distance is 1-3mm.

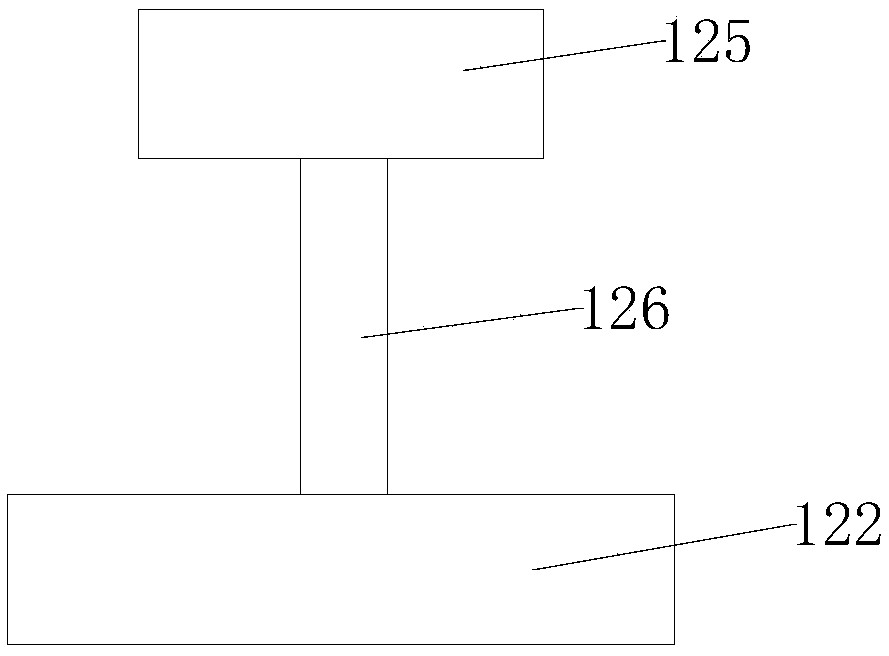

[0026] A groove 121 is provided on the bottom surface of the circular arc platform of the fan-shaped part 12, and ...

Embodiment 2

[0031] The difference between this embodiment and the first embodiment is that the bottom edge of the triangular part 11 is connected to the blade body 2 through integral molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com