High-strength concrete with strong durability and good workability, and preparation method thereof

A high-strength concrete and water-reducing agent technology, applied in the field of concrete, can solve the problems of concrete workability (reduced workability, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

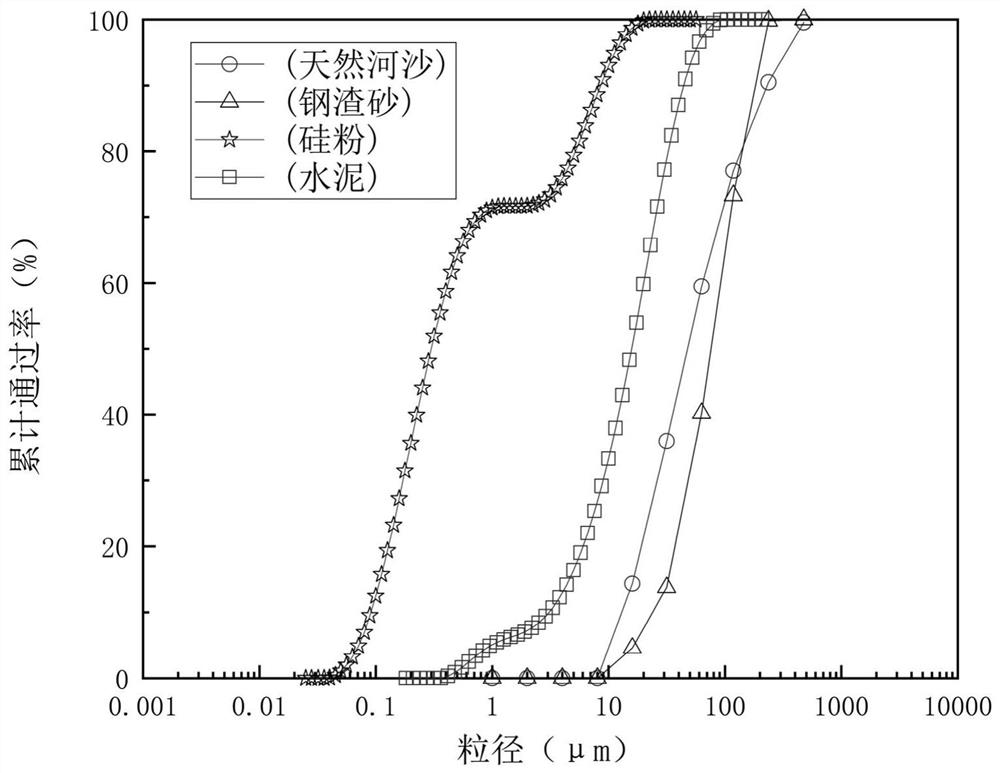

[0028] This embodiment provides a high-strength concrete, which is composed of the following raw material components in parts by weight: 153.09 parts of water, 727.16 parts of cement, 28.39 parts of silica fume, 506.85 parts of steel slag sand, 397.5 parts of natural river sand, 810 parts of granite gravel, 11.33 parts of polycarboxylate water reducer; water-binder ratio is 0.202.

[0029] Among them, the cement used is P.O42.5R ordinary Portland cement produced by Guangzhou Shijing Cement Company, with an apparent density of 3100kg / m 3 ; The silica fume used is 99-grade silica fume produced by Sichuan Langtian Resources Comprehensive Utilization Co., Ltd., with an apparent density of 2300kg / m 3 The steel slag sand used is the converter slag produced by Hunan Valin Xiangtan Iron and Steel Co., Ltd., which is crushed and sieved into steel slag sand with a particle size of 0.075-5mm and an apparent density of 3379kg / m 3 The polycarboxylate water reducer used is a polycarboxylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com