Sealing device for electrolytic copper foil

A sealing device and electrolytic copper foil technology, applied in the direction of sealing device, electrolytic process, electrolytic components, etc., can solve the problems of forming burrs, large, poor sealing effect, gaps, etc., to achieve not easy to loosen, good sealing, quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

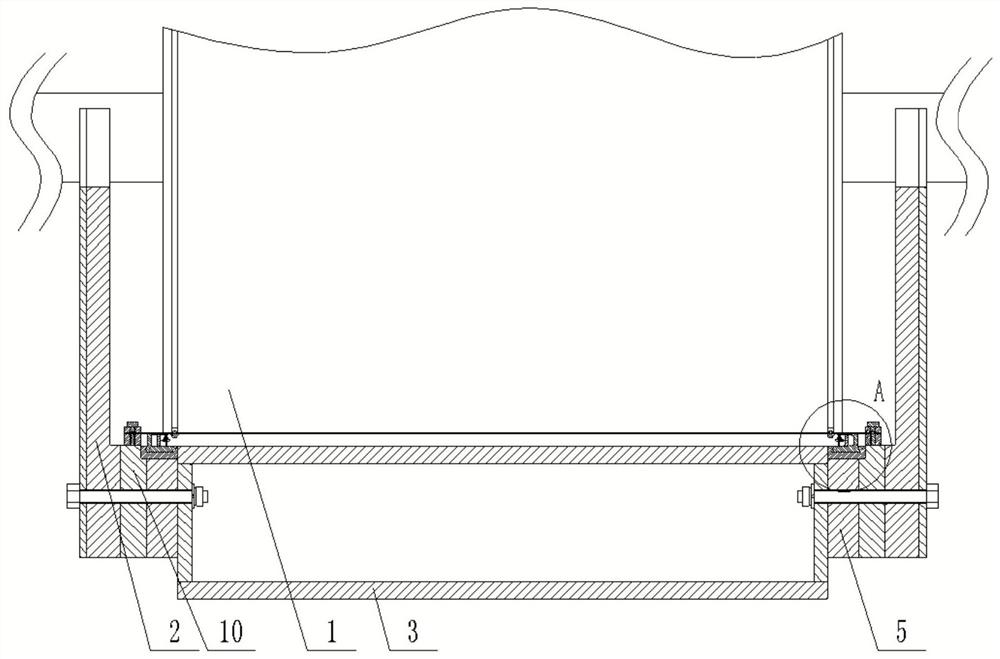

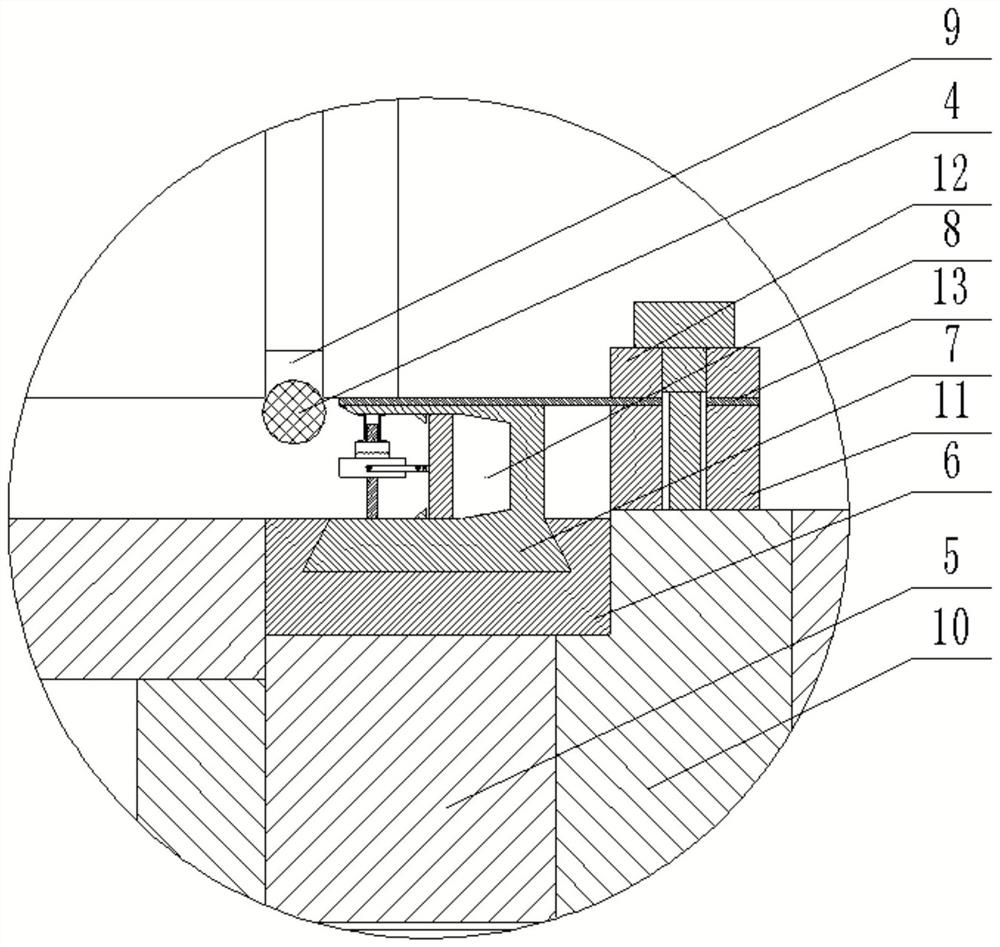

[0027] refer to Figure 1-5 This embodiment provides a sealing device for electrolytic copper foil, including support plates 2 located on both sides of the cathode roll 1 and a support frame 3 located at the bottom of the cathode roll 1, and sealing rings 4 are clamped at both ends of the cathode roll 1, An arc-shaped bottom plate 5 is fixedly connected between the support plate 2 and the support frame 3, and a base 6 is fixedly connected to the arc-shaped bottom plate 5. A sealing block 7 is clamped inside the base 6, and the top of the sealing block 7 abuts against the cathode roller 1, sealing The block 7 is provided with an accommodation groove 8, and a pretension assembly is fixedly arranged in the accommodation groove 8, and the pretension assembly is connected with a control part, and the control part and the pretension assembly are fixedly connected with a limiting part; the control part controls the pretension assembly to The sealing block 7 is supported to make the s...

Embodiment 2

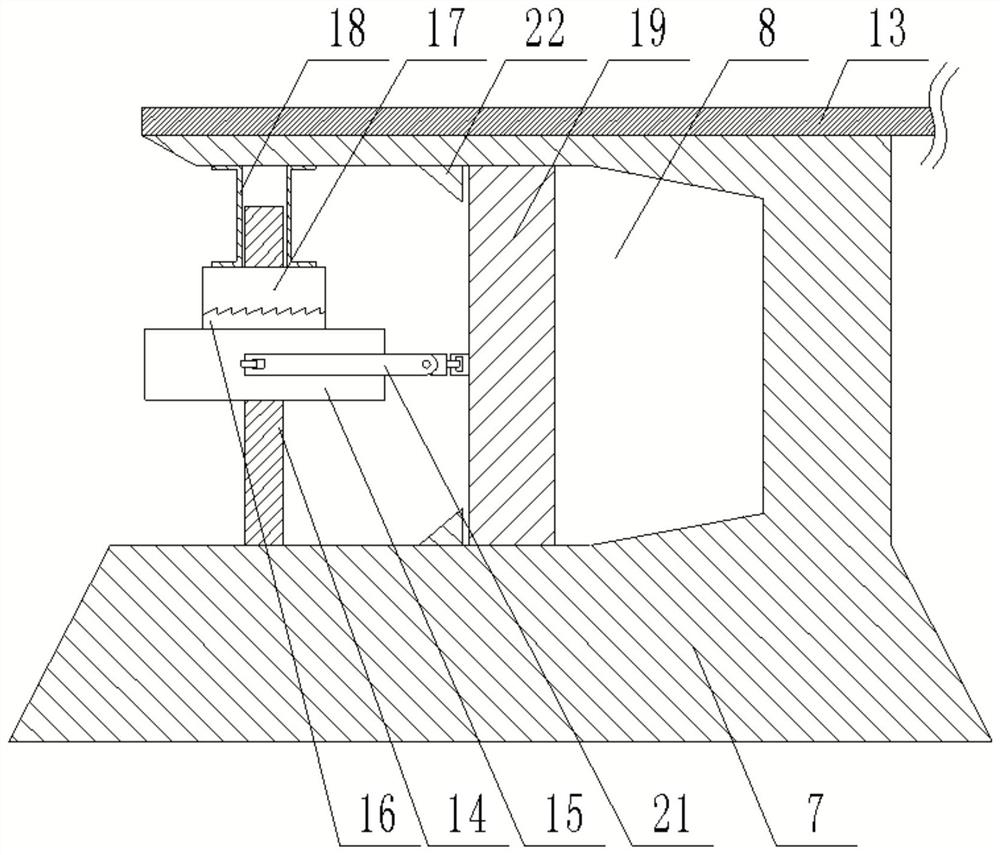

[0041] refer to Image 6 , this embodiment provides a sealing device for electrolytic copper foil. The difference between this embodiment and Embodiment 1 is that there are several blades 23 fixedly connected to the hinged side of the rotating block 15 and the pull rod 21, and the blades 23 are not connected to the pull rod. 21 interferes, when the electrolyte flows to the vicinity of the rotating block 15, first move the blade 23, thereby driving the rotating block 15 to rotate, and then push the sliding block 19 to slide, when the electrolyte returns, it will drive the rotating block through the blade 23 15 is rotated in the opposite direction, so that the engaging block 16 on the rotating block 15 is away from the top block 17, and at the same time drives the sliding block 19 to slide back, preventing the accommodating groove 8 from making the sliding block 19 slide back, causing the engaging block 16 to always engage with the top block 17 , the rotating block 15 cannot tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com