Hydraulic box girder inner mold disassembling and assembling trolley

A technology of hydraulic box and inner mold, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of inconvenient, fast and efficient disassembly, inability to disassemble bolts or steel bars quickly, and single function, and achieve the effect of easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

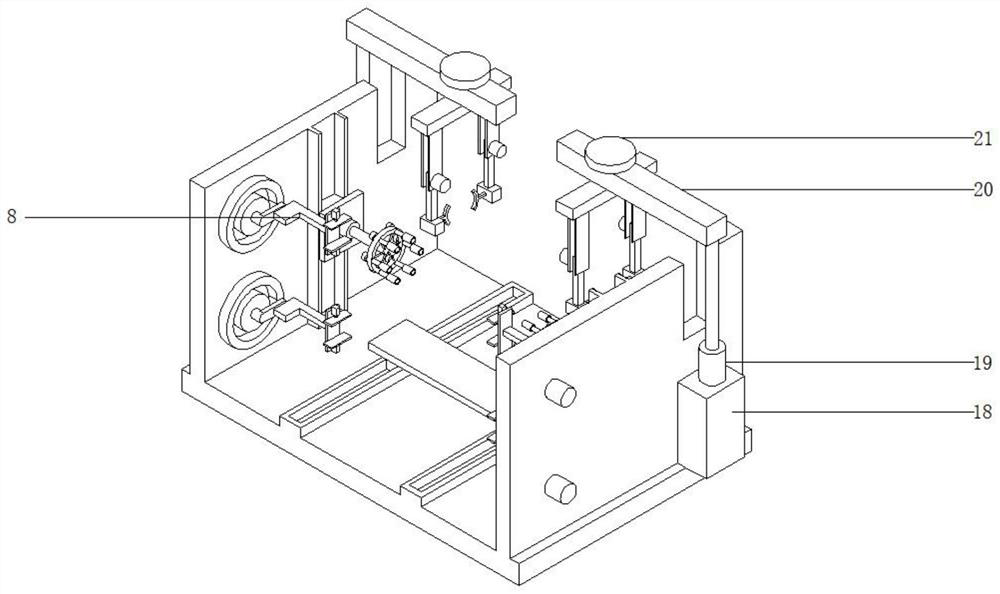

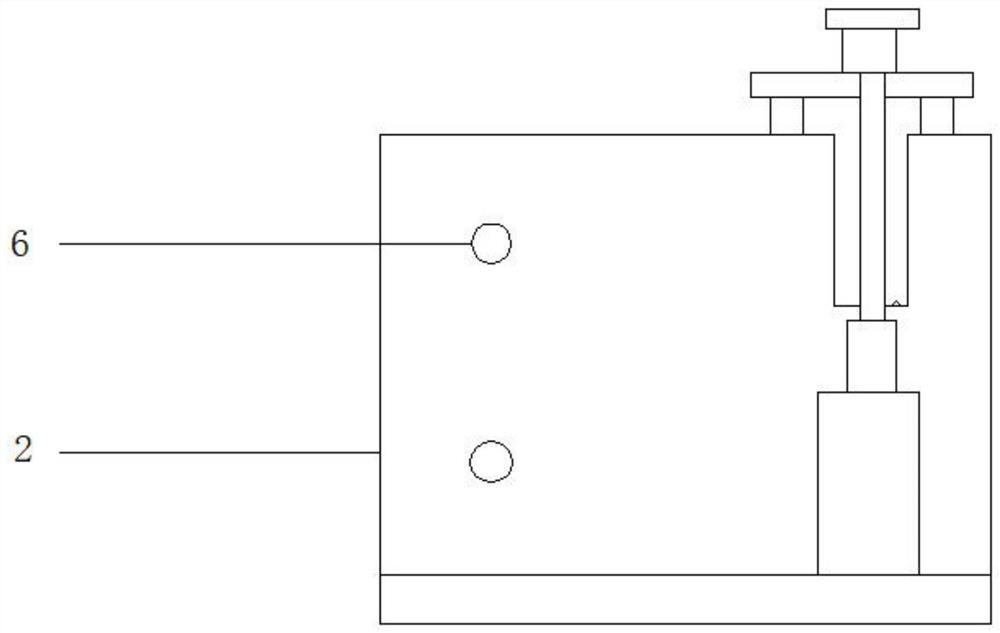

[0032] Embodiment 1, an electromagnetic guide rail 12 is vertically arranged in the middle of the column plate 2, and a movable block is embedded inside the electromagnetic guide rail 12, and a square plate 13 is vertically connected to the outside of the movable block, and a hydraulic cylinder is arranged at the outer middle of the square plate 13 Two 14, the output end of the hydraulic cylinder two 14 is connected with the ring disc 15, and several upright rods are equidistantly arranged on the ring disc 15, and the outer end of the upright rod is connected with the post tube 16, and the inside of the post tube 16 is hollow, through Electromagnetic guide rail 12 is used to drive square plate 13 and hydraulic cylinder 2 14 to move up and down, and anchor rods and steel bars can be dismantled into column pipe 16 for easy disassembly.

[0033] The inboard that is positioned at ring disk 15 is also provided with motor two 17, and the output end of motor two 17 is connected with v...

Embodiment 2

[0035] In the second embodiment, the fastening structure includes a strip plate 22, and a stand frame 23 is arranged symmetrically on both sides of the strip plate 22. The inside of the stand frame 23 is hollow and a motor 24 is arranged outside the bottom end. The output end of four 24 is connected with connecting rod 25, and the outer end of connecting rod 25 is also connected with hydraulic cylinder four 26, and the output end of hydraulic cylinder four 26 is connected with buckle plate 27, through this design, motor four 24 can be used to adjust the connecting rod 25 angle, use hydraulic cylinder 4 26 to adjust the clamping strength of pinch plate 27.

[0036] The pinch plate 27 is one of arc shape or strip shape, which is convenient for clamping and fixing the steel bar or the anchor rod.

Embodiment 3

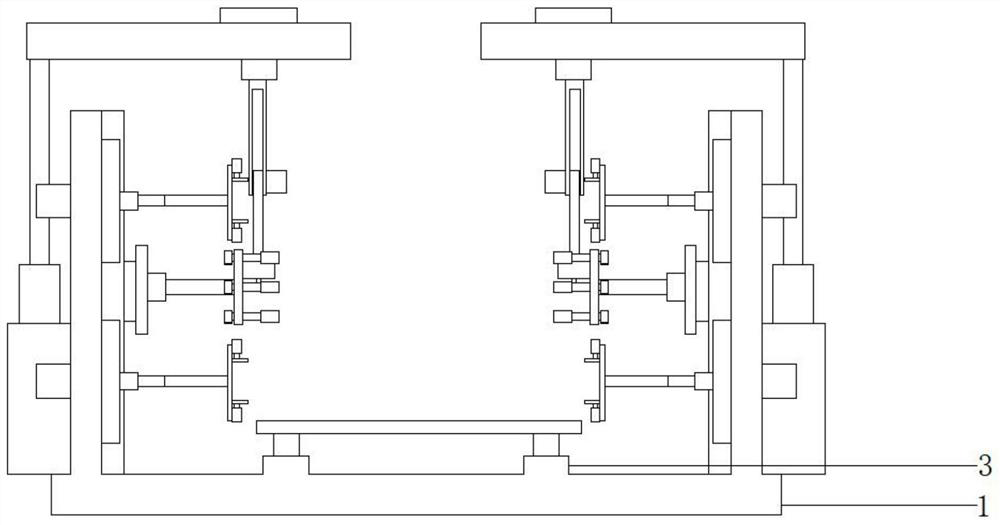

[0037] Embodiment 3, the load-bearing assembly includes a top pressure plate 28 and a bottom pressure plate 29, and the bottom of the bottom pressure plate 29 is provided with two insertion rods 30, and the two insertion rods 30 are inserted into the corresponding guide rail frame 3, and the top pressure plate 28 and the bottom pressure plate 29 There are also several buffer structures arranged between them, which can play the role of support and load bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com