Lock mechanism with state indication function

A technology of state indication and lock mechanism, which is applied in the field of lock mechanism that can display the state of the lock, and can solve problems such as complex manufacturing process assembly, limited rotation angle of the lock, and poor structural stability of the indicator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

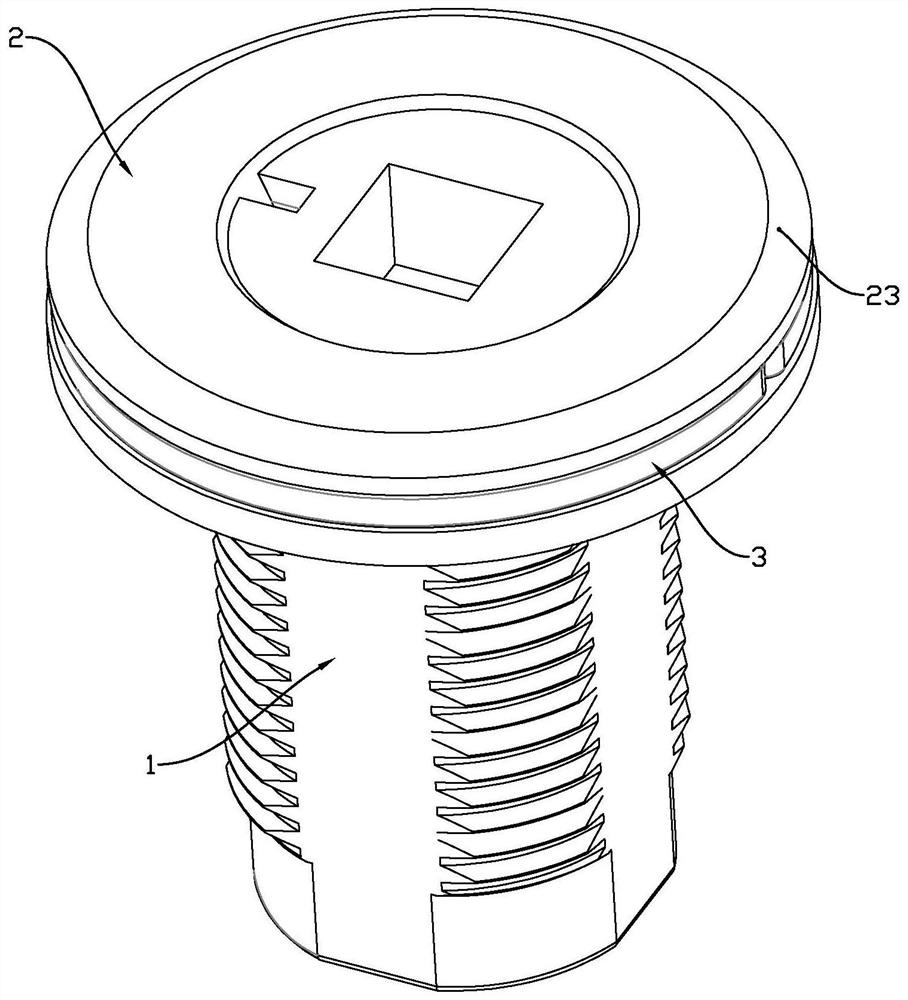

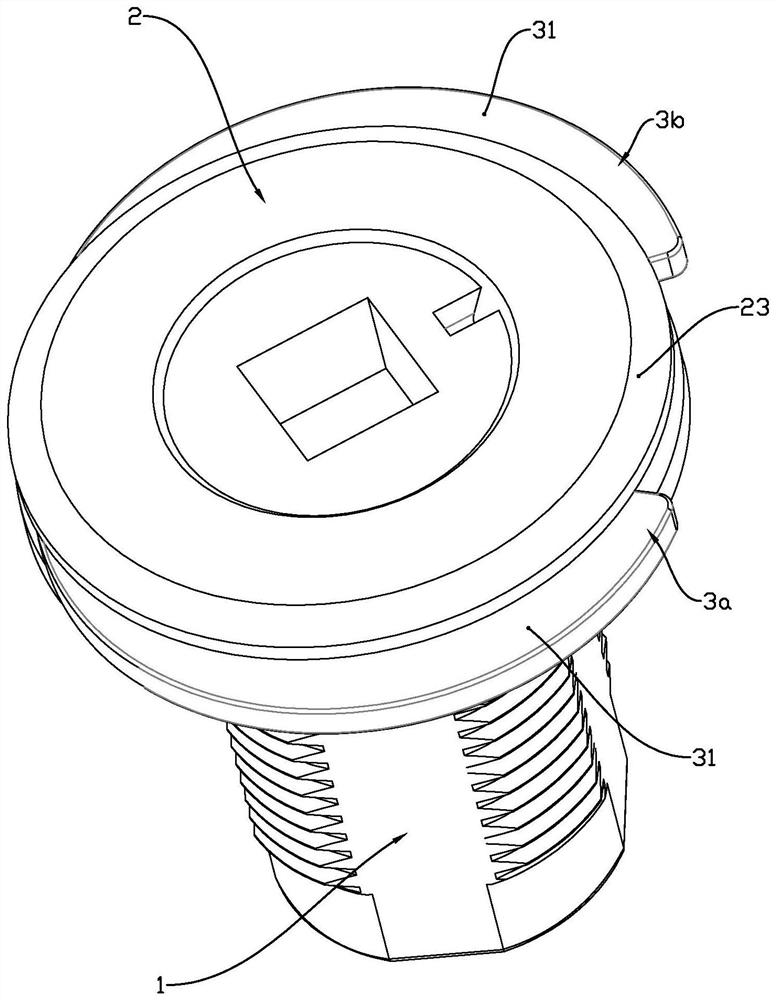

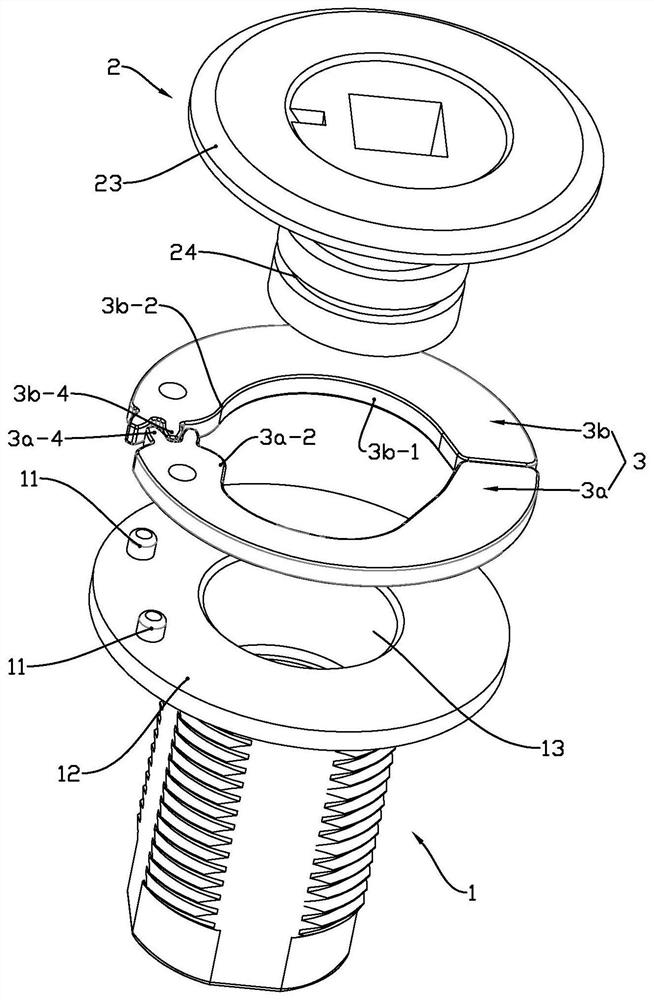

[0021] See attached Figure 1~8 , a lock mechanism with a state indication function disclosed in the present invention, comprising a housing 1, a cover 2 and an indicator 3, the cover 2 has a central axis 21, and is installed to surround the The central axis moves relative to the housing 1. The indicator 3 is inserted between the cover 1 and the housing 2. The indicator 3 has an indicating portion 31 in a covering relationship with the cover 1. The indicator 3 is Pivotably mounted on the housing 1 around a protrusion 11 , the indicator 3 moves from the central axis 21 relative to the cover 2 when the cover 2 is rotated from the latched position to the unlocked position. Move radially outward, so that the indicating portion 31 of the indicator 3 is no longer in a covering relationship with the cover; the cover corresponds to the unlocking and latching action of the locking mechanism, and the cover 2 rotates from the latched position to the unlocked position At this time, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com