Roasting device and roasting method for high-purity graphite powder production

A technology of high-purity graphite powder and roasting equipment, which is applied in descaling equipment, chemical instruments and methods, waste heat treatment, etc., can solve the problems affecting the processing efficiency of high-purity graphite and the decline of roasting effect, and achieve self-cleaning and energy saving , to ensure the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

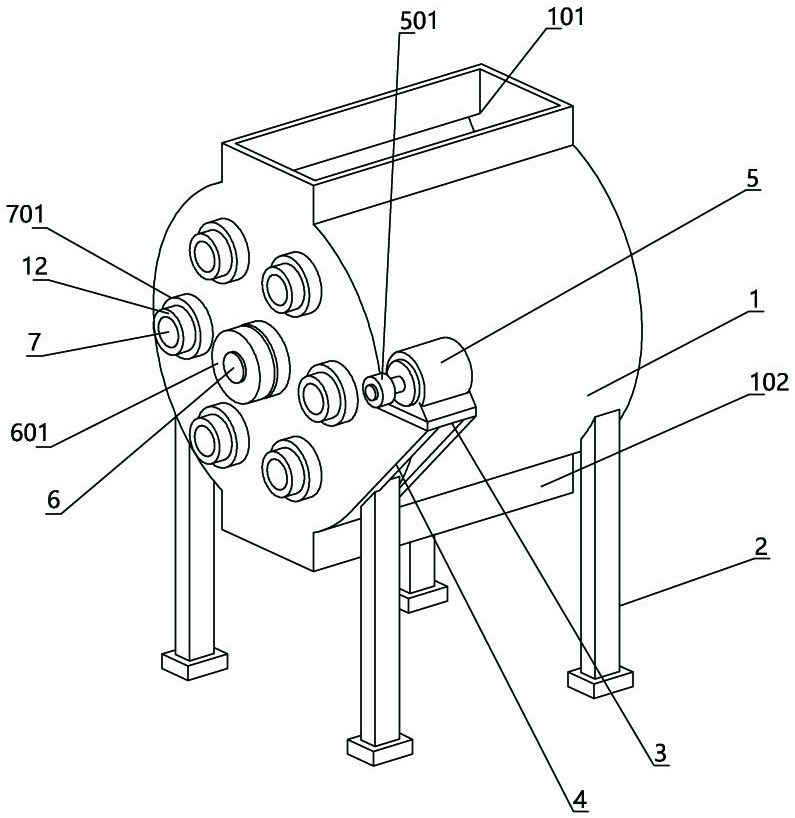

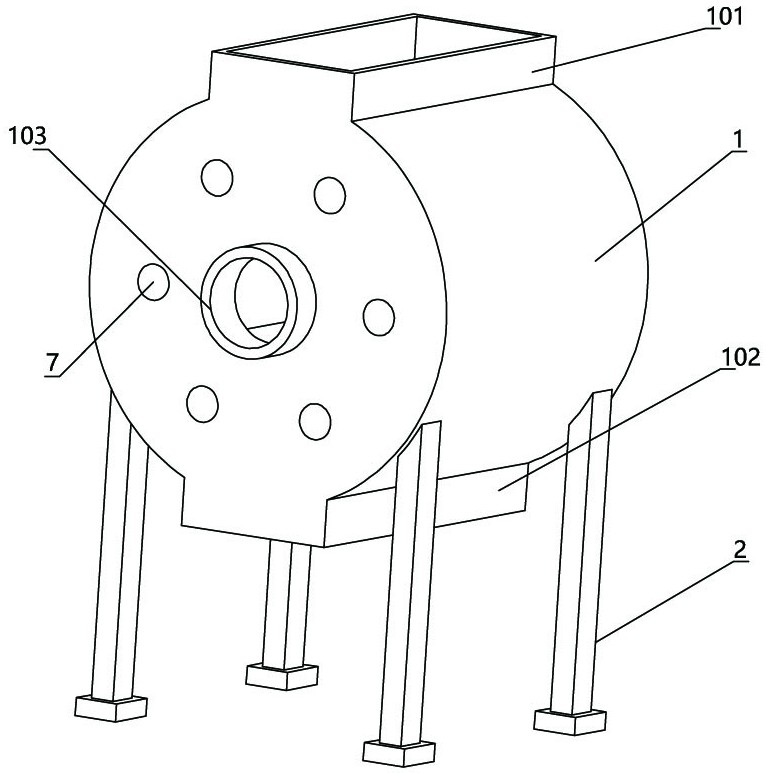

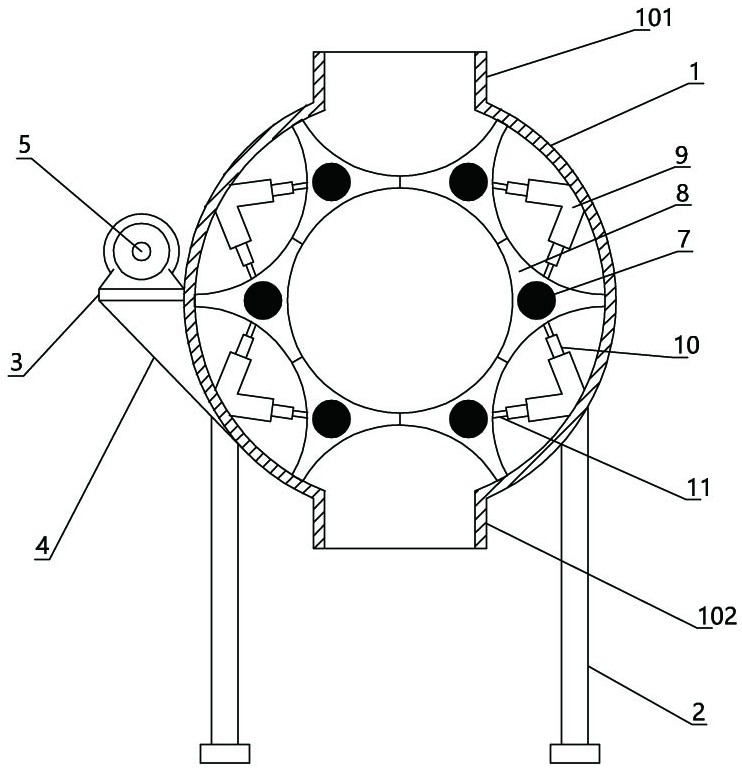

[0021] Such as Figure 1-6 As shown, a roasting device and roasting method for high-purity graphite powder production include a hollow cylindrical roasting box 1 inside, a triangular plate 8 arranged inside the roasting box 1, and the upper side of the roasting box 1 is provided with a feed port 101, and the lower side of the roasting box 1 is provided with a discharge port 102, four legs 2 are fixed on the lower side of the roasting box 1, a fixed seat 3 is fixed on the curved side wall of the roasting box 1, and a fixed seat 3 is fixed on the lower side of the roasting box 1. Reinforcing rib 4, and reinforcing rib 4 is fixedly connected with roasting case 4, motor 5 is fixed on fixed base 3, the output shaft of motor 5 is fixed with first transmission wheel 501, and the rear side middle part of roasting case 1 is provided with air inlet 103 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com