Soft package lithium battery module structure capable of effectively preventing heat diffusion in battery pack

A soft-pack lithium battery and module structure technology, applied in battery pack parts, secondary batteries, structural parts, etc., can solve problems such as combustion or explosion, large-scale thermal diffusion, etc., to prevent thermal diffusion and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

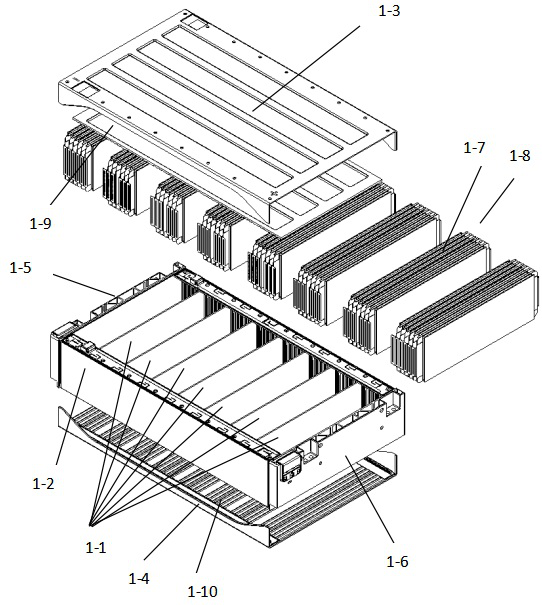

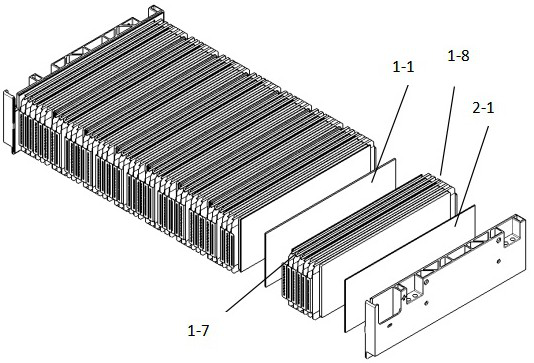

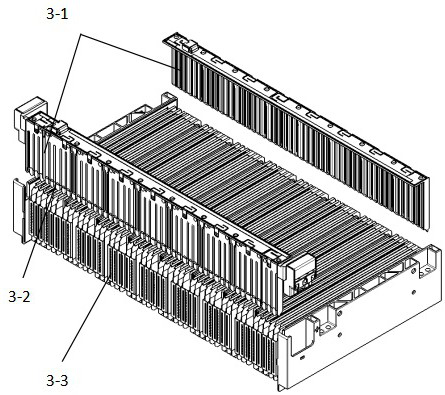

[0027] Such as figure 1 As shown, a soft pack lithium battery module structure that effectively prevents thermal diffusion in the battery pack includes a module, and the internal space of the module is composed of a heat insulation board 1-1, a fireproof board 1-2, an upper cover The lower cover plate 1-4, the left end plate 1-5 and the right end plate 1-6 are divided into several areas, and a battery unit 1-8 is placed in each area, and the battery unit 1-8 is composed of the battery cells 1-7 Composed of series and parallel stacking, the lower part of the upper cover plate 1-3 is coated with thermal conductive structural adhesive 1-9, the upper part of the lower cover plate 1-4 is coated with thermal conductive structural adhesive 1-10, and the upper cover plate 1-4 is coated with thermal conductive structural adhesive 1-10. 1-3 and the lower cover plate 1-4 are pasted and fixed to the battery cell 1-7 by applying glue, and the module uses heat-conducting structural adhesive...

Embodiment 2

[0033] Such as figure 1 As shown, a soft pack lithium battery module structure that effectively prevents thermal diffusion in the battery pack includes a module, and the internal space of the module is composed of a heat insulation board 1-1, a fireproof board 1-2, an upper cover The lower cover plate 1-4, the left end plate 1-5 and the right end plate 1-6 are divided into several areas, and a battery unit 1-8 is placed in each area, and the battery unit 1-8 is composed of the battery cells 1-7 Composed of series and parallel stacking, the lower part of the upper cover plate 1-3 is coated with thermal conductive structural adhesive 1-9, the upper part of the lower cover plate 1-4 is coated with thermal conductive structural adhesive 1-10, and the upper cover plate 1-4 is coated with thermal conductive structural adhesive 1-10. 1-3 and the lower cover plate 1-4 are pasted and fixed to the battery cell 1-7 by applying glue, and the module uses heat-conducting structural adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com