Nitrogen trifluoride production pollution discharge equipment and process method

A nitrogen trifluoride and process method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as affecting production progress, strong corrosion, complicated operation procedures, etc., and achieve strong production continuity and economical efficiency. The effect of the amount of alkali used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

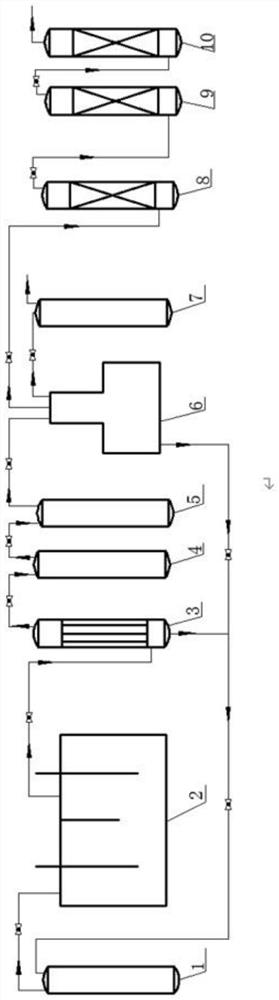

[0028] Nitrogen trifluoride production blowdown equipment in the present embodiment, as figure 1 As shown, it includes an electrolytic cell 2, the anode gas outlet of the electrolytic cell 2 is connected with the air inlet at the bottom of the cooler 3 through a pipeline, and the gas outlet at the top of the cooler 3 is connected with the air inlet at the top of the balance tank 4 through a pipeline, and the The air outlet at the top of the balance tank 4 is connected with the air inlet at the top of the negative pressure tank 5 through a pipeline, and the air outlet at the top of the negative pressure tank 5 is connected with the air inlet at the top of the cold trap 6 through a pipeline, and an air outlet of the cold trap 6 passes through Pipeline is connected with crude product tank 7, and another gas outlet of described cold trap 6 is connected with cracking tower 8 bottom gas inlets by pipeline, and described cracking tower 8 top gas outlets are connected with alkali washi...

Embodiment 2

[0030] Adopt the equipment among the embodiment 1 to carry out the processing method of nitrogen trifluoride production blowdown in the present embodiment and comprise the following steps:

[0031] S1, using molten NH in the electrolytic cell 2 3 -xHF is used as the electrolyte system to electrolyze nitrogen trifluoride gas, the molar ratio of the electrolyte system in the electrolytic cell 2 is x=2.5, the electrolysis temperature is 100°C, and the pressure is 0.01MPa;

[0032] S2. The electrolytic gas produced by the anode of the electrolytic cell 2 enters the cooler 3 through a pipeline for cooling. The temperature of the cooler 3 is -100° C. and the pressure is 0 MPa. Part of the HF in the electrolytic gas is cooled in the cooler. 3 is liquefied to obtain a cooled gas;

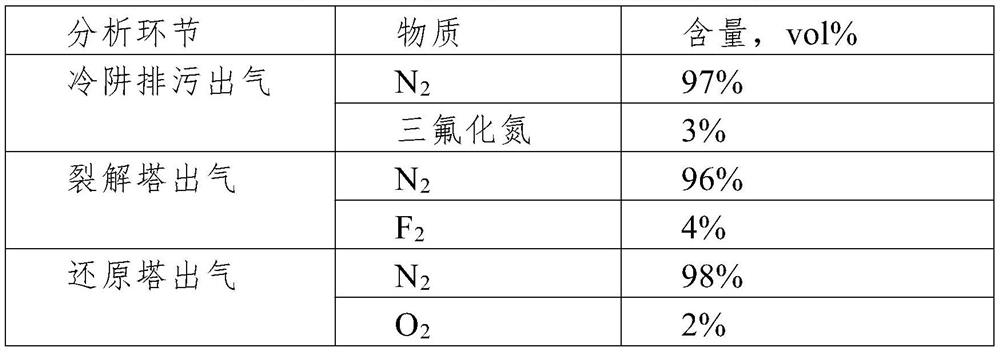

[0033] S3, passing the cooled gas generated in S2 through the balance tank 4, the negative pressure tank 5 and the cold trap 6 in sequence, the temperature of the balance tank 4 is 20°C, and the pressure i...

Embodiment 3

[0043] Adopt the equipment among the embodiment 1 to carry out the processing method of nitrogen trifluoride production blowdown in the present embodiment and comprise the following steps:

[0044] S1, using molten NH in the electrolytic cell 2 3 -xHF is used as the electrolyte system to electrolyze nitrogen trifluoride gas, the molar ratio of the electrolyte system in the electrolytic cell 2 is x=3, the electrolysis temperature is 90°C, and the pressure is 0MP;

[0045] S2. The electrolytic gas produced by the anode of the electrolytic cell 2 enters the cooler 3 through a pipeline for cooling. The temperature of the cooler 3 is -70° C., and the pressure is -0.012 MPa. Part of the HF in the electrolytic gas is Cooler 3 is liquefied to obtain cooled gas;

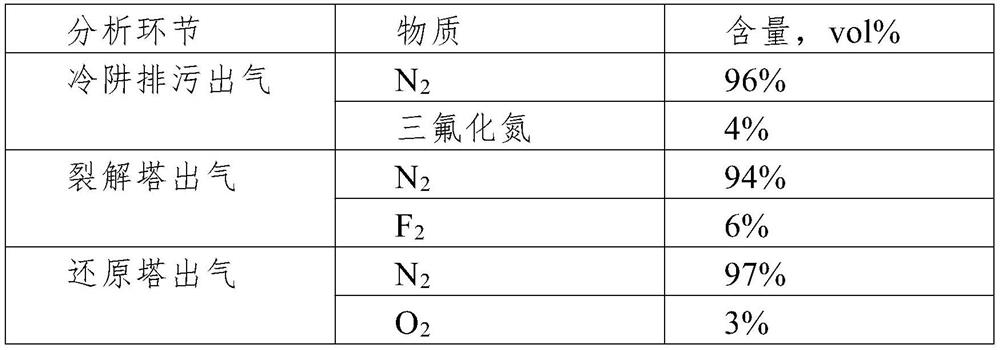

[0046] S3, passing the cooled gas generated in S2 through the balance tank 4, the negative pressure tank 5 and the cold trap 6 in sequence, the temperature of the balance tank 4 is 20°C, and the pressure is -0.002MPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com