Treatment method and device for effluent brine

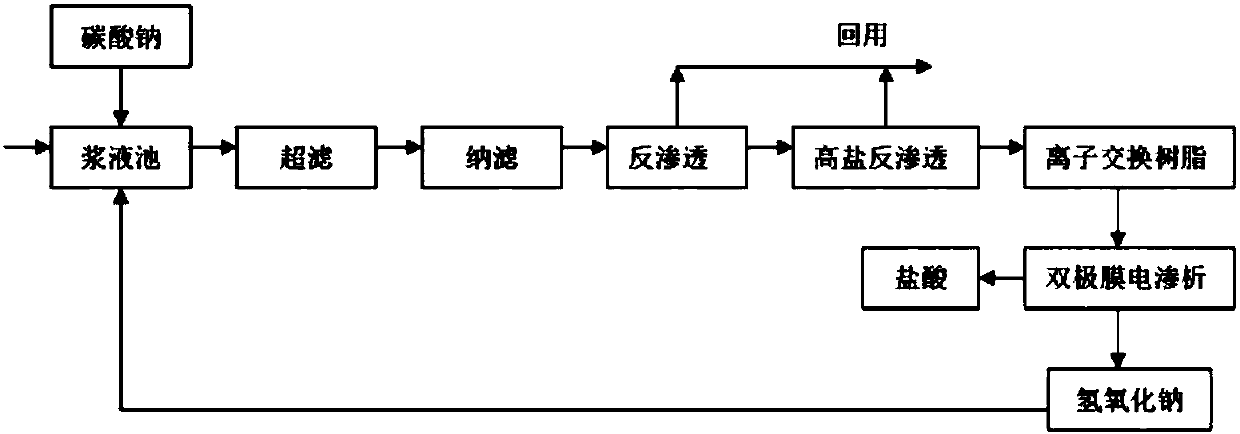

A treatment method and technology of a treatment device, which are applied in the directions of processing wastewater treatment, textile industry wastewater treatment, multi-stage water treatment, etc., can solve the problems of difficult reuse, polyvalent ions and organic pollutants, etc. Higher, saving effect of the amount of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

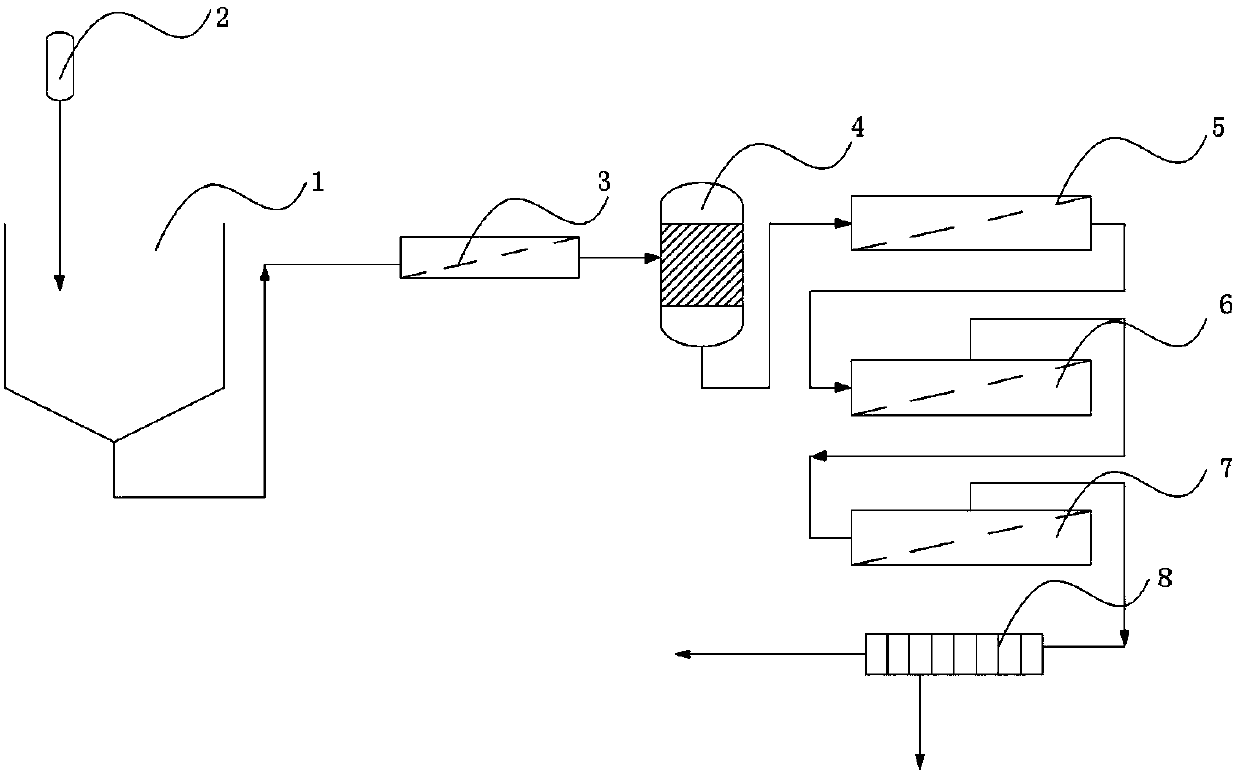

Method used

Image

Examples

Embodiment 1

[0082] The wastewater treated in this example is the waste brine obtained after the blue anthraquinone disperse dye wastewater of a certain printing and dyeing factory undergoes biochemical, oxidation, and membrane concentration, and the mixed waste brine produced by a paper mill. Wastewater brine water quality: the average concentration of ammonia nitrogen is 1.06mg / L, the concentration of COD is 164.5mg / L, the content of sodium chloride is 1800mg / L, the concentration of sulfate ions is 850mg / L, the concentration of calcium ions is 65mg / L, the concentration of magnesium ions 50mg / L.

[0083] (1) The mixed waste brine is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than the Mg in the completely precipitated brine 2+ Concentration greater than 0.1g / L, Na 2 CO 3 The dosing concentration is higher than the Ca in the complete precipitation brine 2+ and Ba 2+ Th...

Embodiment 2

[0090] The wastewater treated in this example is the waste brine obtained after the blue anthraquinone disperse dye wastewater of a certain printing and dyeing factory undergoes biochemical, oxidation, and membrane concentration, and the mixed waste brine produced by a paper mill. Wastewater brine water quality: the average concentration of ammonia nitrogen is 1.06mg / L, the concentration of COD is 164.5mg / L, the content of sodium chloride is 1800mg / L, the concentration of sulfate ions is 850mg / L, the concentration of calcium ions is 65mg / L, the concentration of magnesium ions 50mg / L.

[0091] (1) The mixed waste brine is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than the Mg in the completely precipitated brine 2+ Concentration greater than 0.20g / L, Na 2 CO 3 The dosing concentration is higher than that of Ca in completely precipitated brine 2+ and Ba 2+ ...

Embodiment 3

[0098] The wastewater treated in this example is the waste brine obtained from the 2,3-dichloro-6-carboxylchloroquinoxaline reactive dye wastewater of a printing and dyeing factory after biochemical, oxidation and membrane concentration and the mixed waste brine produced by the paper mill . Wastewater brine water quality: the average concentration of ammonia nitrogen is 1.55mg / L, the concentration of COD is 198.2mg / L, the content of sodium chloride is 1950mg / L, the concentration of sulfate ion is 1040mg / L, the concentration of calcium ion is 78mg / L, the concentration of magnesium ion 65mg / L, and 0.15wt% of 2,3-dichloro-6-carboxylic acid chloroquinoxaline.

[0099] (1) The mixed waste brine is discharged into the slurry tank, mixed and reacted with the dosing agent containing sodium hydroxide and sodium carbonate, and the concentration of NaOH is higher than the Mg in the completely precipitated brine 2+ Concentration greater than 0.15g / L, Na 2 CO 3 The dosing concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Current intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com