Automatic paper guiding mechanism for paper winding machine

A paper winding machine and paper rolling technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of the safety of personnel contacting the operating equipment, the failure of separation between the paper strip and the paper threading roller core, and the blowing point. Different problems, to achieve the effect of improving the flexibility of use, improving the effect of blowing, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

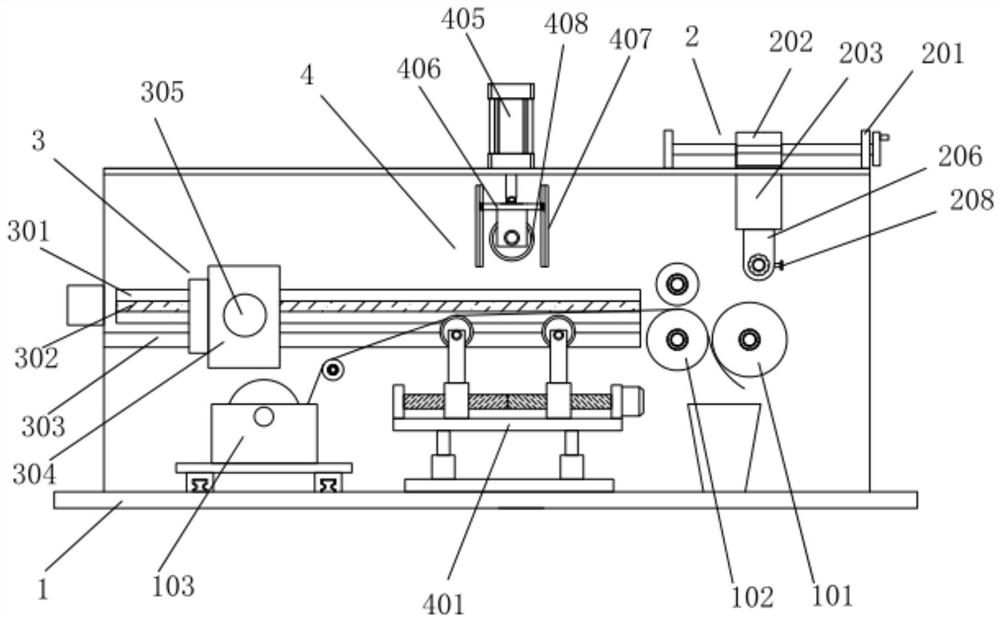

[0037] see Figure 1-Figure 3 As shown, the present invention is a mechanism for automatic paper leading of a paper winding machine. The paper winding machine platform 1 includes an upper horizontal plate, a bottom plate and a vertical plate arranged between the upper horizontal plate and the bottom plate. The paper winding machine platform 1 is provided with a paper threading roll core 101 for paper transfer, and a multi-dimensional pneumatic stripping mechanism 2 is arranged on the winder table 1 and above the paper threading roll core 101, and the pneumatic stripping mechanism 2 is used to The paper strip on the tailing core 101 is blown off.

[0038]When in use, the air pipe 207 in the pneumatic stripping mechanism 2 is adjusted in multiple dimensions, so that the air pipe 207 is adjusted to the best blowing angle to the paper threading roll core 101, thereby improving the blowing of the air pipe 207 to the paper strip on the paper threading roll core 101. away from the e...

Embodiment 2

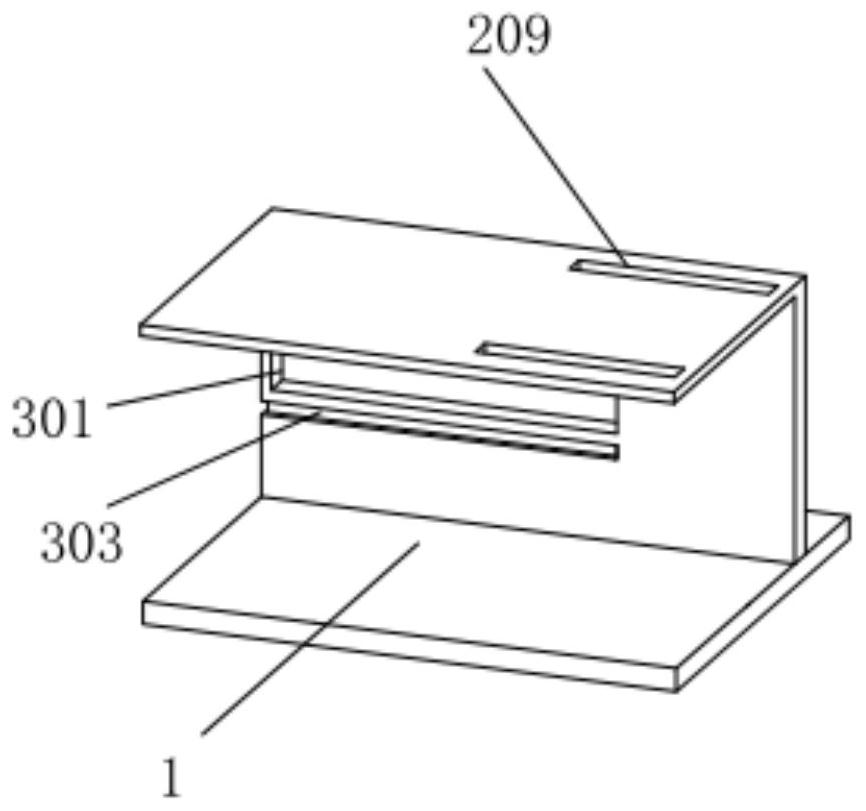

[0046] refer to Figure 1-Figure 4 As shown, the implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that a winding paper traction mechanism 3 is provided on the vertical plate of the winding machine table 1 and on the left side of the winding core 101. The roll paper traction mechanism 3 is used to pull the paper passing through the paper threading roller core 101 to the roll paper winding stand 103 for winding, and the roll paper winding stand 103 is detachably connected to the bottom plate of the paper winding machine 1 , and the roll paper winding stand 103 is provided with a winding roller;

[0047] When in use, through the setting of the roll paper traction mechanism 3, the paper is adsorbed by the pneumatic suction cup in the adsorption chamber 304 during the paper rolling process, and the suction chamber 304 transmits the drawn paper to the roll paper rewinding station Frame 103 for rewinding, that is, abandoning the trad...

Embodiment 3

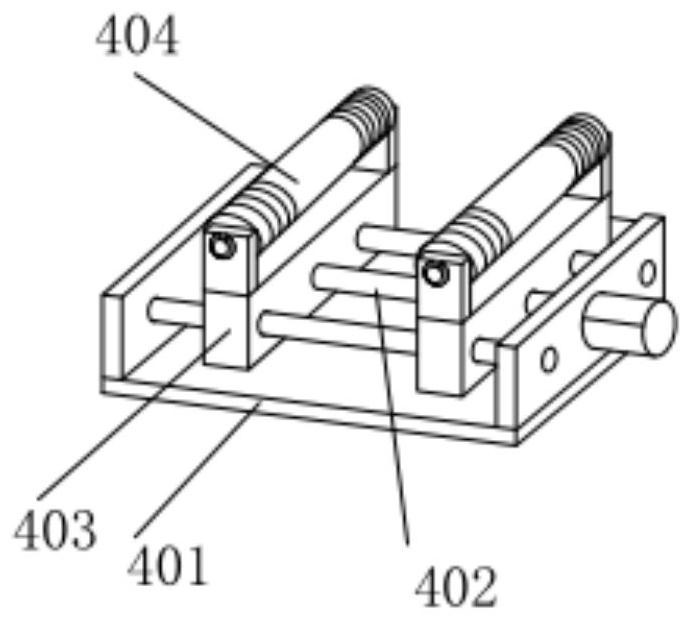

[0053] refer to Figure 1-Figure 5 As shown, the implementation of this embodiment is basically the same as that of Embodiment 1, the difference is that a roll paper positioning mechanism 4 is provided on the paper winding machine table 1 and on the left side of the paper threading roller core 101, and the roll paper positioning Mechanism 4 includes a lower support frame 401 and an upper support frame for paper clamping. The lower support frame 401 is arranged on the bottom plate of the reeling machine table 1. The lower support frame 401 is in a U-shaped structure, and the lower support frame 401 The screw three 402 is arranged inside, the threads of the two ends of the three screw 402 along the center line direction are opposite, and the two ends of the screw three 402 are symmetrically provided with the nut seat three 403, and the top of the nut seat three 403 is provided with a lower support roller 404, the upper support frame includes a hydraulic cylinder 405 fixedly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com