Heavy-load ultra-long energy-saving self-lubricating stacking machine

An energy-saving and self-lubricating technology, which is applied in the direction of engine lubrication, mechanical equipment, engine components, etc., to achieve the effect of large lifting force, stable transmission, and reduced lifting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

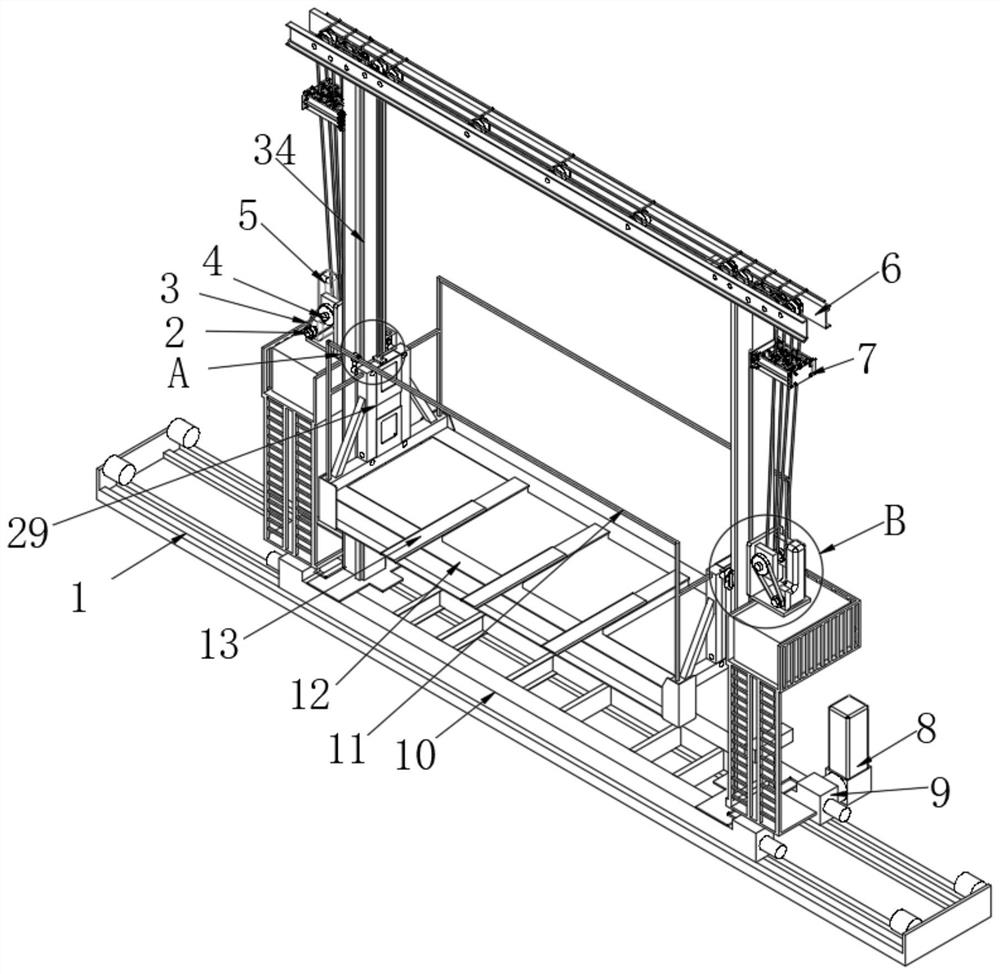

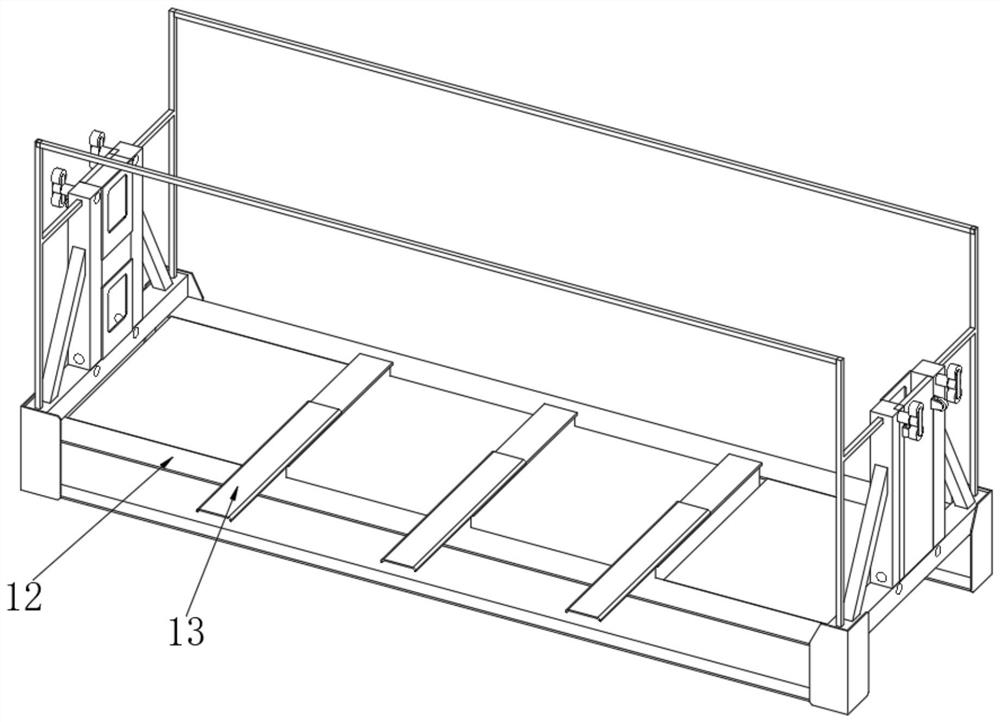

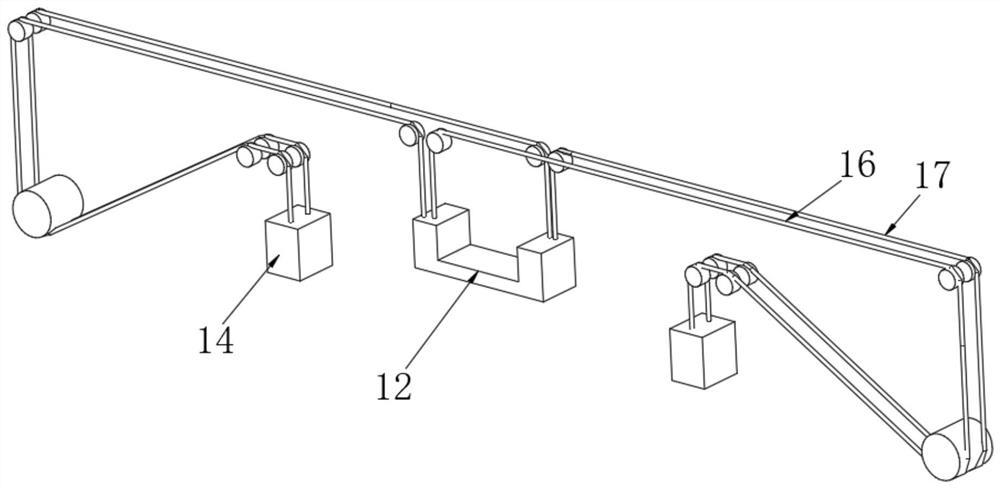

[0025] Such as Figure 1-5 As shown, a heavy-duty super-long energy-saving self-lubricating stacker includes a guide rail 1 and a lower beam 10 rolling on the top of the guide rail 1. Both sides of the top of the lower beam 10 are fixedly connected with columns 34, and the two columns 34 is provided with a loading platform 12, and both sides of the loading platform 12 are fixedly connected with the left and right hangers 29 of the loading platform. The guide wheels 28 are stuck on the front and rear sides of the column 34 and form a rolling cooperation relationship with the column 34, so that the left and right hangers 29 of the cargo platform can move up and down along the column 34, and then drive the cargo platform 12 to move up and down, and the cargo platform The top of 12 is slidingly connected with a fork 13 for loading and unloading goods, and the top of the cargo platform 12 is provided with a shape detection rod 11 for limiting the size of the goods beyond the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com