Hydrate mortar system thickening separation device and separation method

A separation device, a technology for hydrates, which can be used in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., and can solve problems such as unfavorable hydrate decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

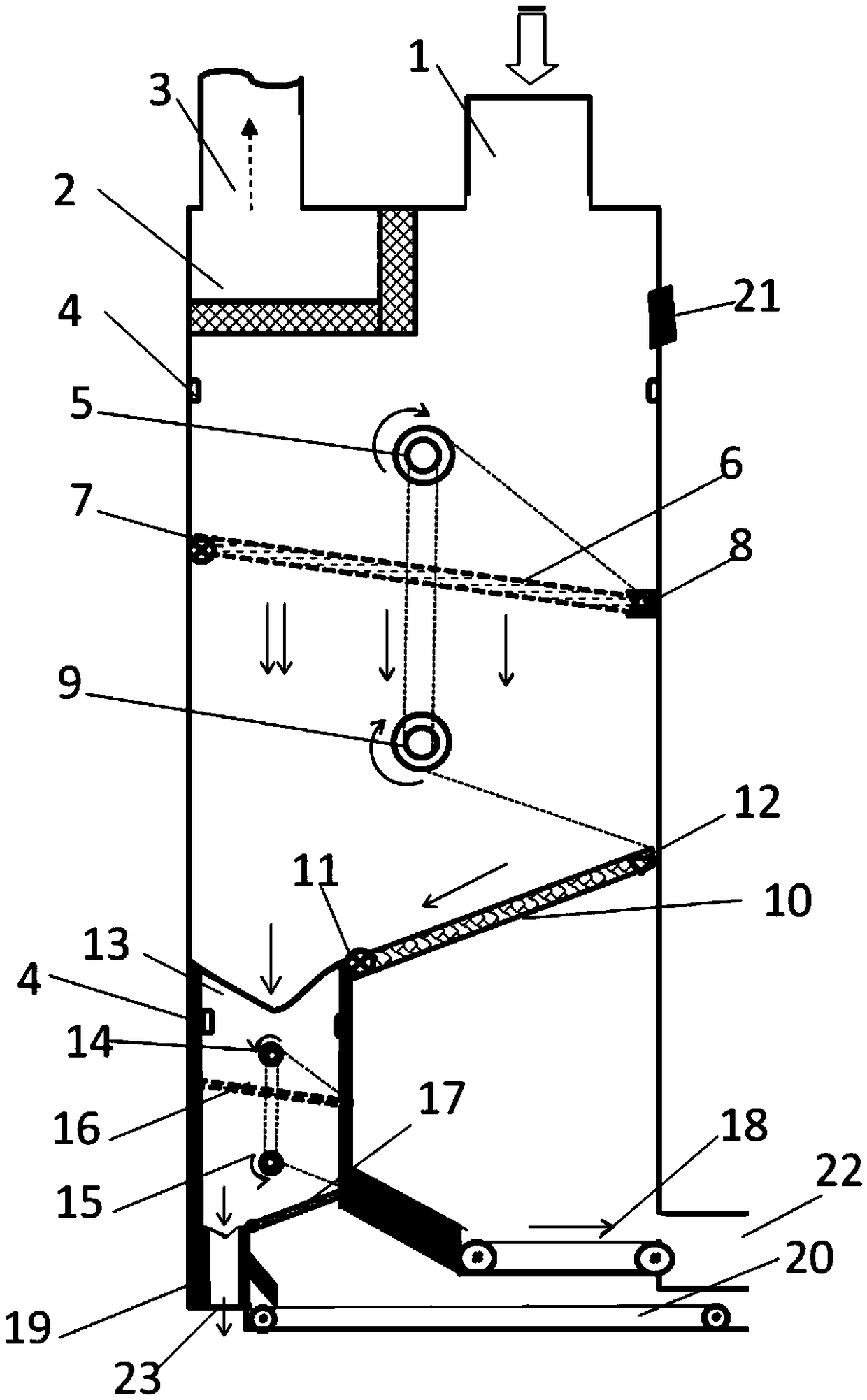

[0027] Example 1, a thickening separation device for a hydrate mortar system. The separation device is installed at the height of the seawater relay station and is used in conjunction with the relay station of the lifting system to separate cold seawater and a small amount of water from the hydrate mortar system. Hydrate decomposition gas, and the separated cold seawater is discharged into the cold seawater reinjection pipeline, a small amount of hydrate decomposition gas is introduced into the upper lifting pipeline, and the separated hydrate thick slurry is introduced into the next step decomposition process for further Decomposition treatment can not only improve the heat energy utilization efficiency in the subsequent hydrate decomposition process, but also help reduce the subsequent lifting pressure and provide more favorable technical support for massive hydrate mining.

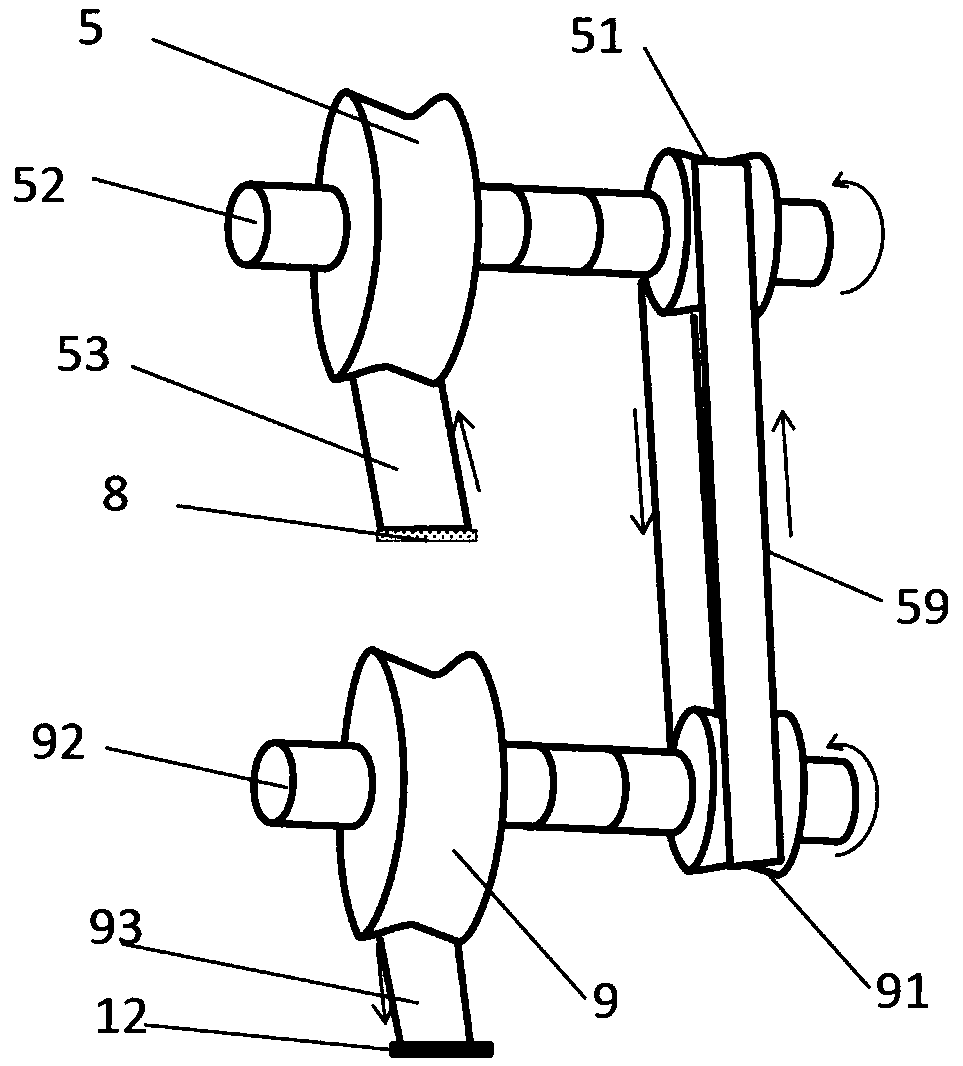

[0028] Such as figure 1 As shown, the hydrate mortar system thickening separation device includes a ...

Embodiment 2

[0035] Embodiment 2, based on the separation method of the hydrate mortar system thickening separation device described in embodiment 1, it comprises the following steps:

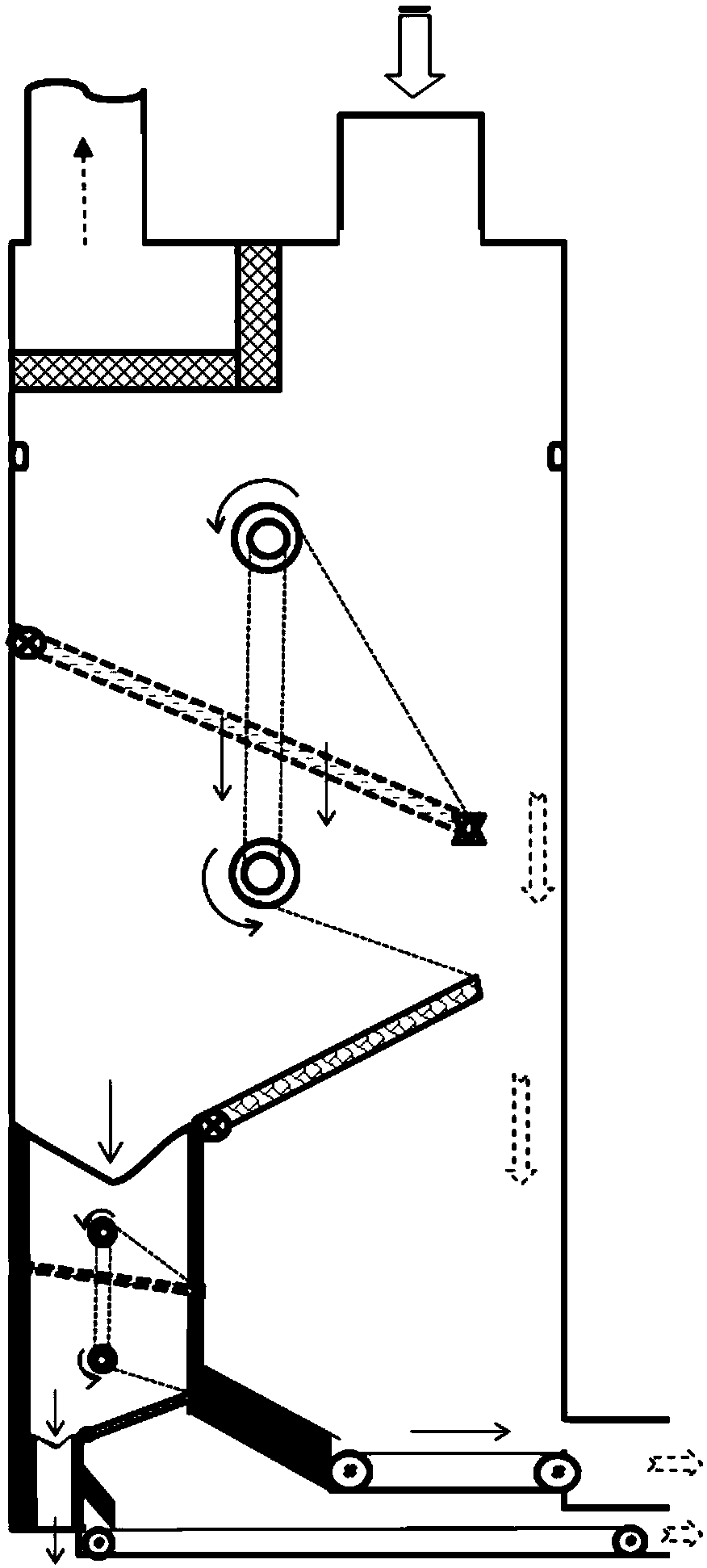

[0036] (1) In the initial state, the separator body and the internal separation structure are in a closed state (such as figure 1 ). When a large amount of cold seawater carries the hydrate mortar system into the tank of the separator, due to the increase in space volume, the flow velocity slows down, and the gas is separated from the cold water hydrate mortar system, passes through the gas separation filter plate and enters the upper pipeline, and the hydrate and cold seawater The mixed system formed with mud and sand sinks down to the first-stage seawater separation filter plate. At this time, the cold seawater continues to penetrate the seawater separation filter plate to seep downwards, enter the first-stage water filtration tank, and drip onto the first-stage seawater separation baffle. The cold sea w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com