Odor-resistant and water-return-resistant floor drain and using method thereof

A floor drain and water floor technology, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of difficult disassembly and repair, poor anti-odor and anti-water backlash effect of floor drains, cumbersome operation, etc., and achieves the effect of easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

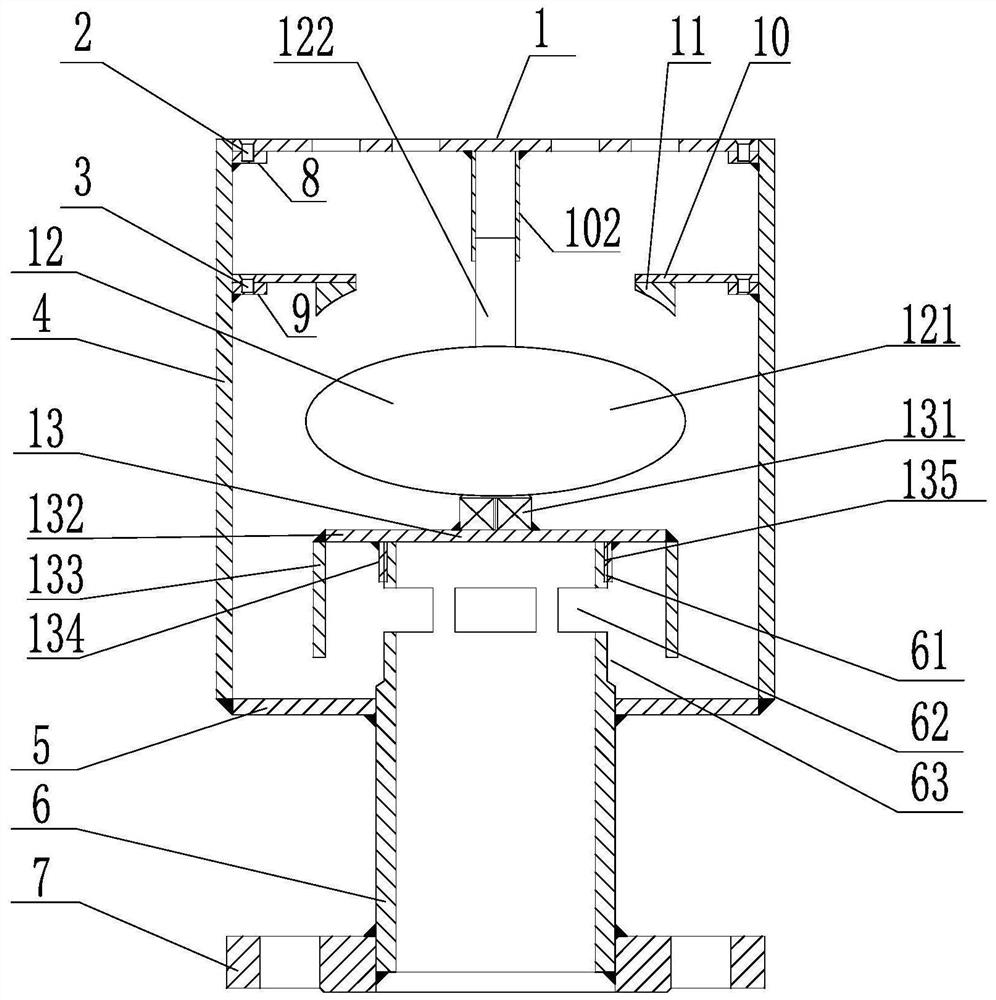

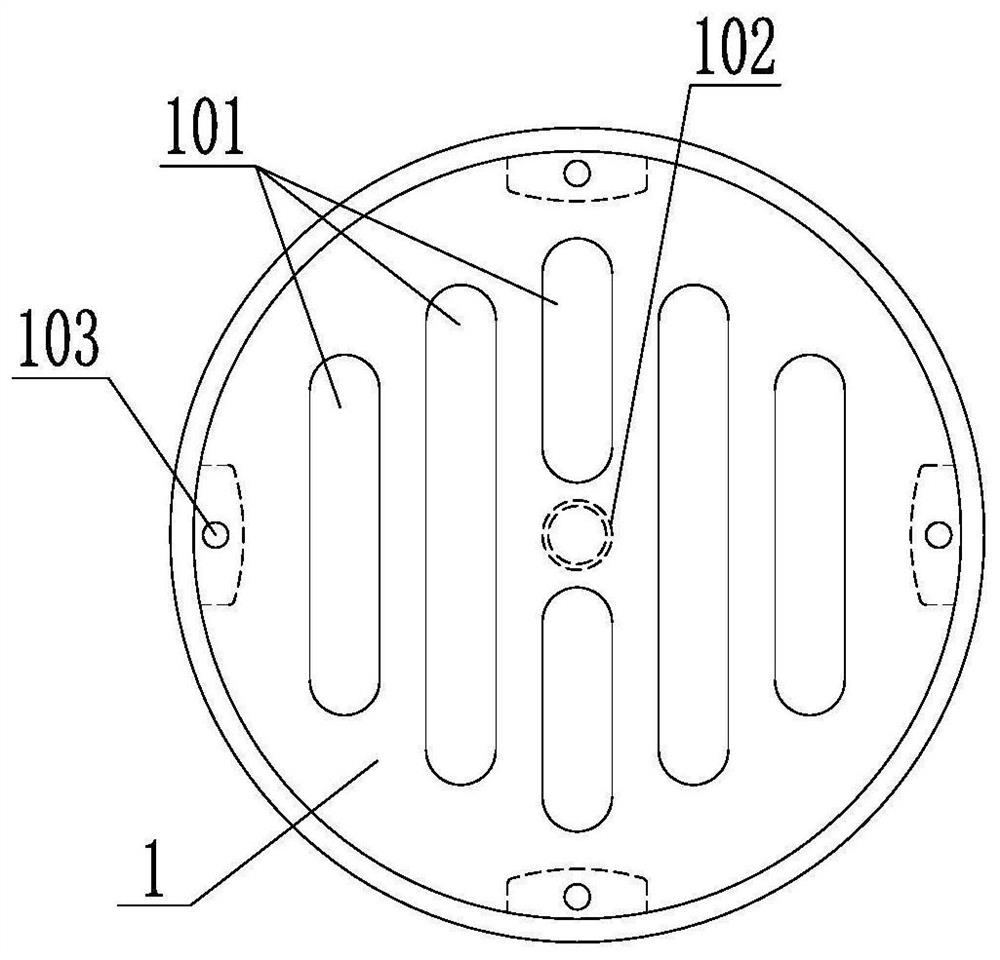

[0077] like Figure 1-2 As shown, the present invention provides a kind of anti-odor floor drain, which is characterized in that, the floor drain includes:

[0078] A cylinder 4, the lower end of the cylinder 4 is fixed with a bottom plate 5;

[0079] The short water outlet pipe 6, the short water outlet pipe 6 runs through the bottom plate 5 and is fixedly connected with the bottom plate 5, the short water outlet pipe 6 extends to the side wall of the cylinder body 4 and has a water hole 62, the The outer surface of the upper end of the outlet short pipe 6 is provided with an external thread 61;

[0080] The floating ball assembly 12, the floating ball assembly 12 is located above the short water outlet pipe 6, including a floating ball 121 and a guide rod 122 fixed above the floating ball 121;

[0081] An annular sealing ring 11, the annular sealing ring 11 is located above the floating ball 121, and the lower end surface of the annular sealing ring 11 has an arc shape mat...

Embodiment 2

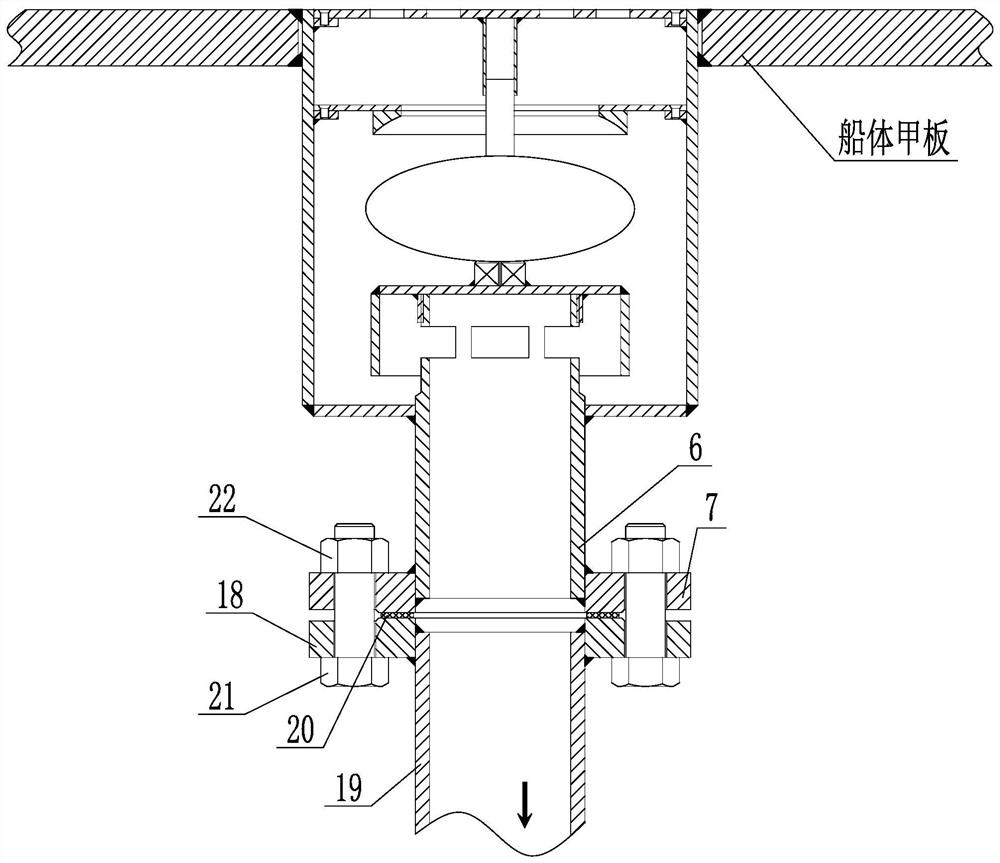

[0096] This embodiment provides a method for using the deodorant and anti-backwater floor drain, such as Figure 1-3 As shown, the method of use includes the following steps:

[0097] S1: Provide the short water outlet pipe 6 and the first flange 7, set the first flange 7 on the lower end of the short water outlet pipe 6 and weld them together reliably, the upper part of the short water outlet pipe 6 is provided with a concave edge 63, and the upper end of the short outlet pipe 6 is provided with an external thread 61;

[0098] S2: provide the cylinder 4, and arrange the welded cover mounting seat 8 and the baffle mounting seat 9 evenly on the inner wall of the cylinder 4;

[0099] S3: Weld and fix the bottom plate 5 at the lower end of the cylinder body 4, pass the short water outlet pipe 6 through the bottom plate 5 and fixedly connect it with the bottom plate 5, and extend the short water outlet pipe 6 to the side wall of the cylinder body 4 to open There are water holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com