Method for detecting pole piece folding and platform for detecting pole piece folding

A detection platform and pole piece technology, applied in the direction of using radiation for material analysis, etc., can solve problems such as the inability to guarantee zero leakage, outflow of defective products, deviation of detection results, etc., and achieve the effect of improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to a method for detecting the turning over of a pole piece, which is beneficial for detecting the turning over of the pole piece of a battery cell.

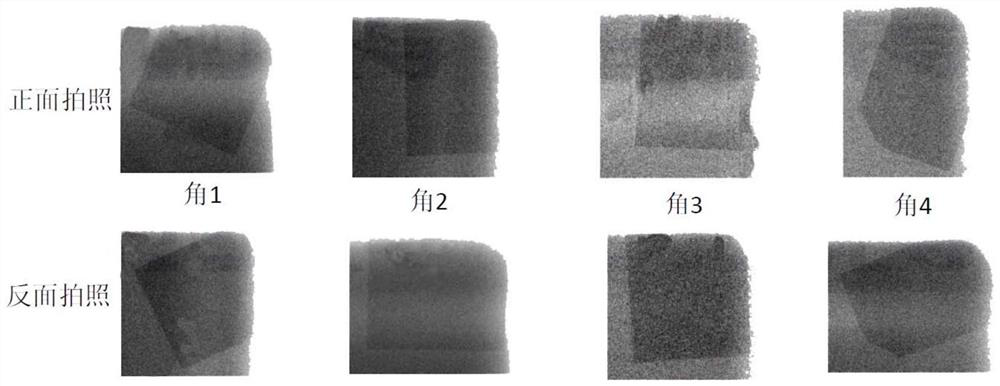

[0034] In this method, the pole piece is placed between the X-ray source and the detection device, and the radiation irradiated by the X-ray source on the pole piece and its periphery is projected on the detection device, which is converted into visible light by the detection device, and then the detection image of the pole piece is generated. .

[0035] Based on the above-mentioned detection principle, in this embodiment, the X-ray source 11 adopts the X-ray source with the highest tube voltage of 130KV; in this way, it can meet the imaging requirements of the pole piece and reduce the damage to the characteristics of the pole piece.

[0036] When testing, it is preferable to set the relevant parameters of the X-ray source as follows: FOD = 150 ~ electrode piece mm, FID = 450 ~ 550mm; single frame ...

Embodiment 2

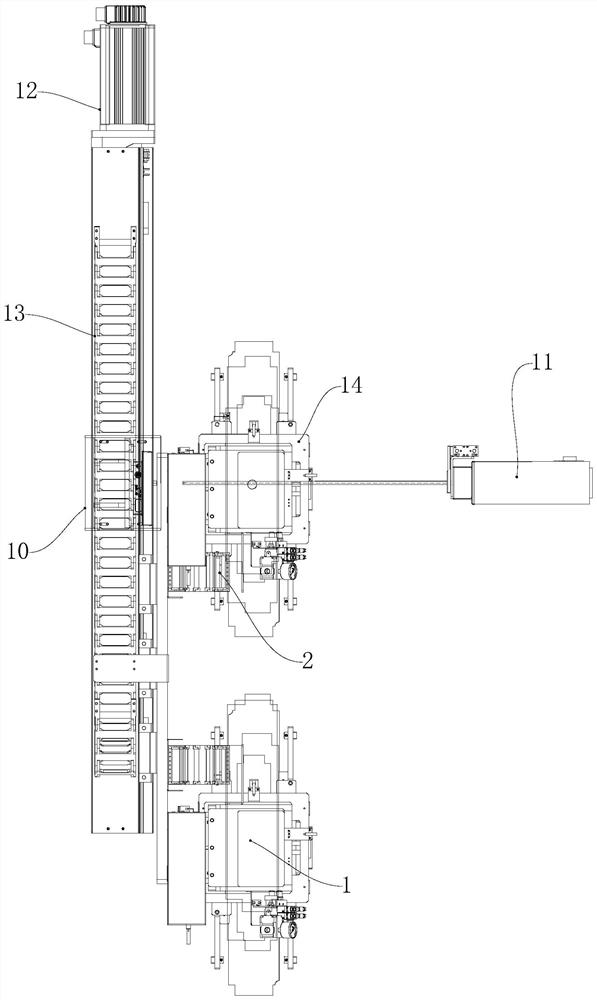

[0053] This embodiment relates to a pole piece turning detection platform, which is set based on the method provided in the first embodiment, and can be used to detect the turning position of the pole piece; an exemplary structure thereof is as follows figure 2 shown.

[0054] The pole piece turning detection platform includes a detection platform 1 , a positioning mechanism 14 disposed on the detection platform 1 , and a detection device 10 and an X-ray source 11 respectively disposed on both sides of the positioning mechanism 14 . Wherein, the pole piece or pole group 2 to be tested can be fixed on the positioning mechanism 14 .

[0055] By setting the positioning mechanism 14, the detection device 10 and the X-ray source 11 on the detection platform 1, the pole piece is fixed on the positioning mechanism 14, the pole piece is irradiated by the X-ray source 11, and the radiation is converted into visible light by the detection device 10 and generated Image; For the folded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com