Production method and production equipment of high-moisture peanut drawing protein

A technology of drawing protein and production method, which is applied in the direction of protein food processing, plant protein processing, protein food ingredients, etc., and can solve the problems of wasteful equipment configuration and power, complicated procedures, and polluted wastewater discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for producing high-moisture peanut silk protein, comprising the following steps,

[0037] Compounding peanut protein powder, soybean protein, wheat protein, and pea protein powder into materials, and mixing the materials in the mixer 1;

[0038] The mixed material is sent into the conditioner 3 through the first screw conveyor 2;

[0039] Inject the seasoning liquid into the conditioner 3 once, and mix the mixed material with the seasoning liquid;

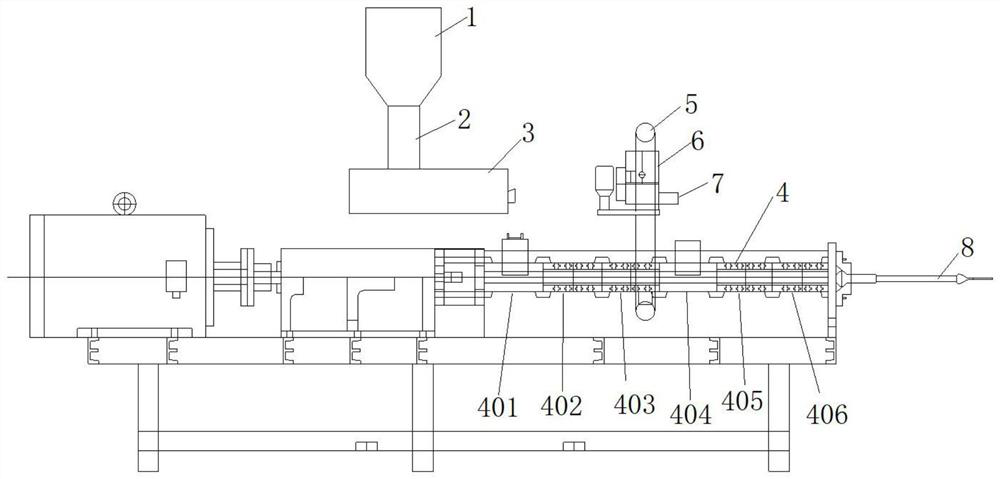

[0040] The mixture of the material and the seasoning liquid is sent into a twin-screw extruder 4, the twin-screw extruder 4 includes a front zone and a rear zone, and the front zone includes a first front zone 401 and a second front zone 402 and a third front zone 403, the temperature of the third front zone 403 is greater than the temperature of the first front zone 401 and lower than the temperature of the second front zone 402;

[0041]After the mixture of the material and the seasoning liquid is preliminarily ...

Embodiment 2

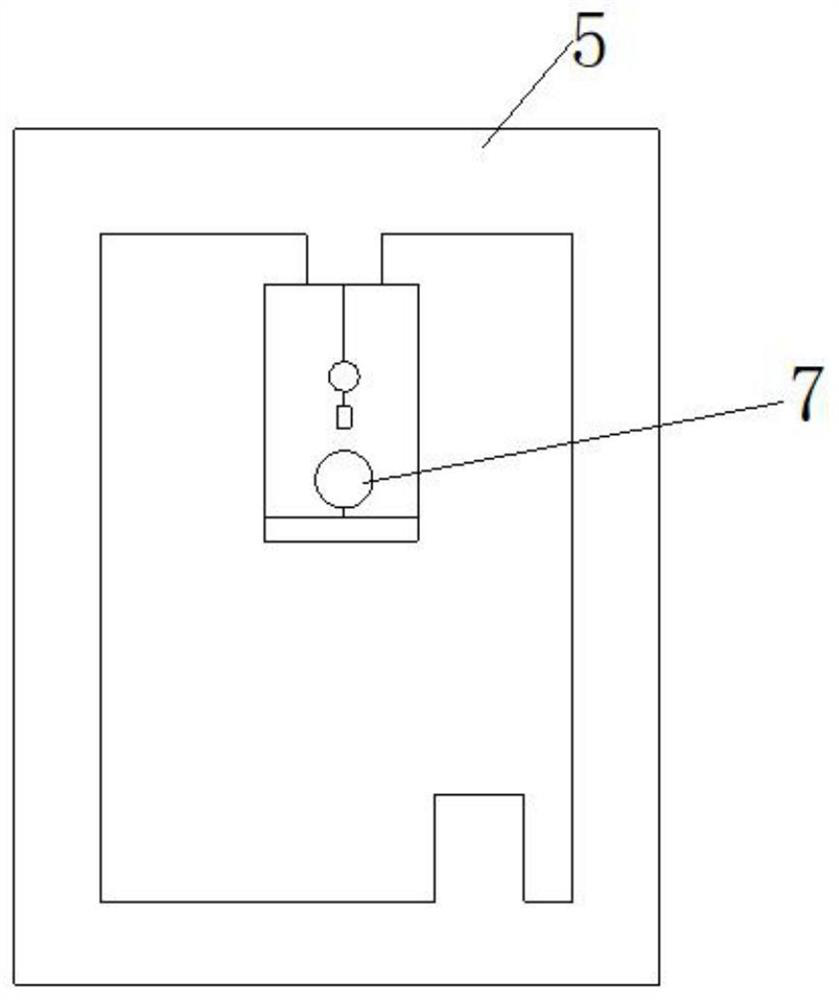

[0061] The production equipment of the high-moisture peanut silk protein production method of embodiment 1, such as figure 1 and figure 2 , including a mixer 1 and a twin-screw extruder 4, the twin-screw extruder 4 includes a front section and a rear section, and the front section includes a first front section 401, a second front section 402 and a third front section 403, The discharge port of the first front area 401 is communicated with the feed port of the second front area 402, and the discharge port of the second front area 402 is connected with the feed port of the third front area 403; the rear area includes the first One rear area 404, the second rear area 405 and the third rear area 406, the discharge port of the first rear area 404 is connected with the feed inlet of the second rear area 405, and the discharge port of the second rear area 405 is connected with the second rear area 405 The feeding port of the third back zone 406 is connected; The feed port is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com