Application of water-based ink in manufacturing of pinch plate, pinch plate and preparation method therefor

A technology of water-based ink and gusset, which is applied in ink, applications, household appliances, etc., can solve the problems of toxicity and other problems, and achieve the effects of low cost, small ink particles, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

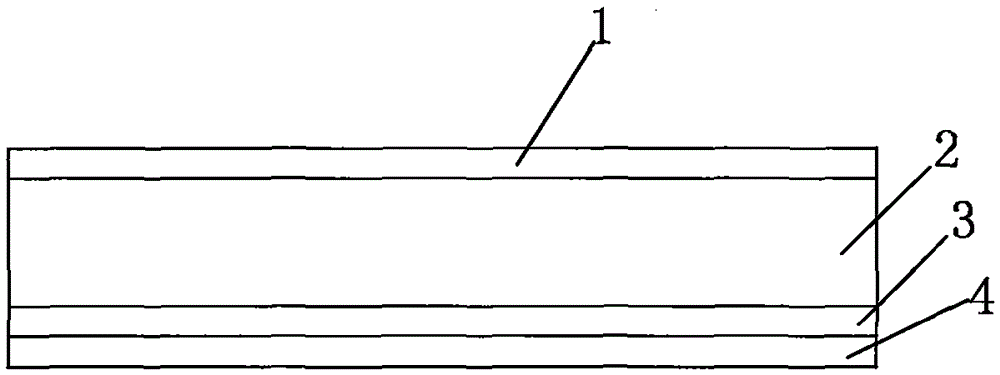

[0030] Embodiment 1: a kind of pinch plate, such as figure 1 As shown, the gusset plate includes a back coating protection layer 1, a metal substrate layer 2, a roller coating topcoat layer 3, and a water-based ink coating layer 4 from bottom to top, and the water-based ink coating layer 4 is A water-based ink coating layer made of water-based ink.

[0031] Wherein, the water-based ink is composed of the following raw materials in mass ratio: 80 parts of water-based polyester resin, 12 parts of water-based amino resin, 1 part of water-based defoamer, 1 part of water-based leveling agent, 0.5 parts of water-based thickener parts, 5 parts of water.

[0032] Wherein, the water-based defoamer is composed of organic polyether ester, mineral oil and alcohol defoamer. The mass ratio of the three is: 25 parts of organic polyether ester, 20 parts of mineral oil, alcohol 30 parts of antifoaming agent; the water-based leveling agent is a fluorocarbon modified polypropylene leveling age...

Embodiment 2

[0053] Embodiment 2: The structure of the pinch plate of this embodiment is the same as that of the embodiment, except that the proportioning of the water-based ink is different:

[0054] The water-based ink used for gussets is composed of the following mass ratio raw materials: 75 parts of water-based polyester resin, 12 parts of water-based amino resin, 1.2 parts of water-based defoamer, 1 part of water-based leveling agent, 0.8 parts of water-based thickener 8 parts of water.

[0055] The water-based defoamer is compounded by mineral oil and silicon defoamer, and the mass ratio of the two is: 27 parts of mineral oil and 15 parts of silicon defoamer.

[0056] A kind of preparation method based on above-mentioned water-based ink, comprises the steps:

[0057] 1. After activating the water-based defoamer and water-based leveling agent according to the production formula, they are used as pre-additives. Specifically, the anti-whitening water is mixed with the water-based level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com