A kind of polymer modified adsorbent, its preparation method and its application

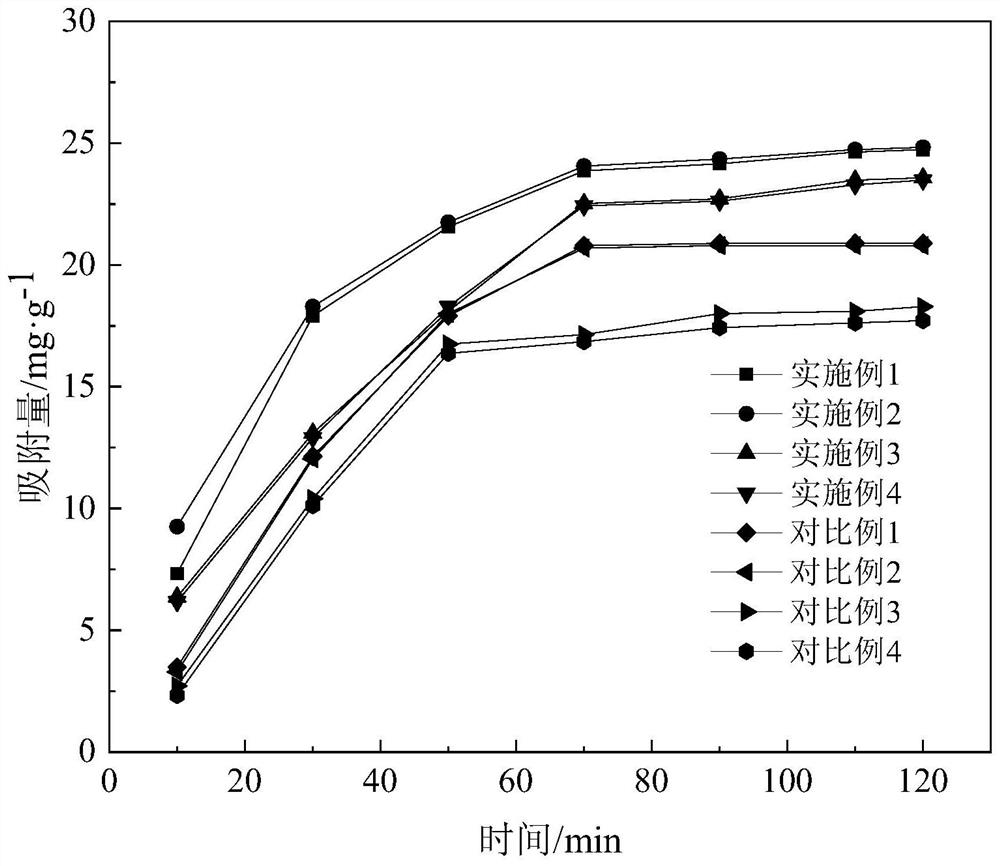

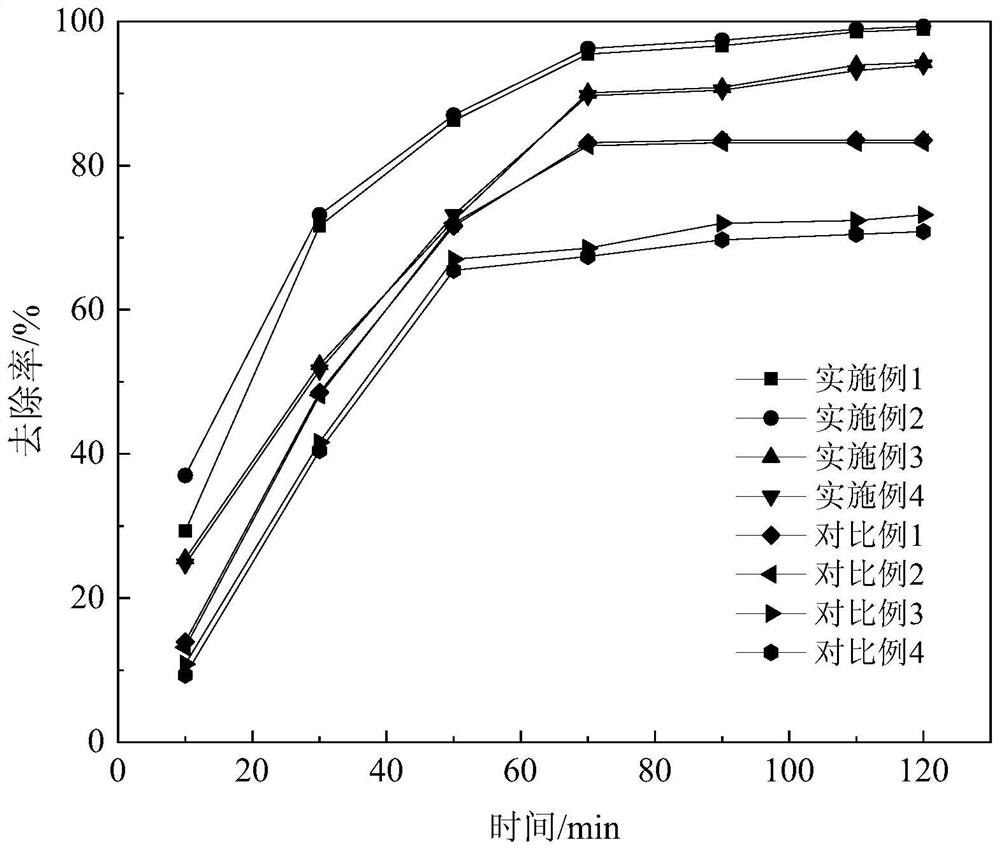

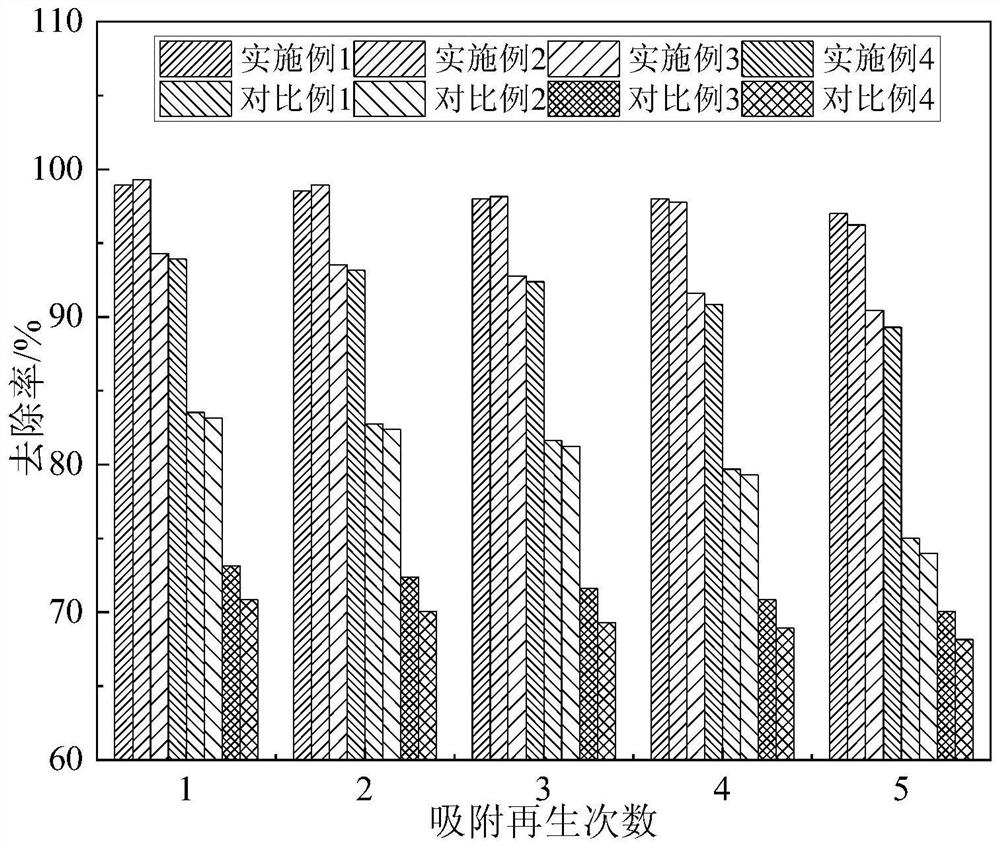

A polymer and adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of poor phosphorus adsorption capacity, poor regeneration and recycling capacity, and high cost, and achieve accelerated removal , Fast adsorption speed, strong regenerative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of 6%-PEI-CaAlLa-LDH:

[0032] At room temperature, 4.44g CaCl 2 , 1.07g AlCl 3 and 0.87g La (NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of deionized water to form a mixed salt solution, and then a polyethyleneimine solution with a concentration of 6 wt% was slowly added to the mixed salt solution to form an imine salt mixed solution. Take 0.5mol / L Na 2 CO 3 The solution was added dropwise to the imide salt mixed solution at a speed of 5 mL / min, and the reaction was carried out to obtain an intermediate reaction solution.

[0033]Keep stirring the intermediate reaction solution until the pH of the intermediate reaction solution = 8, then age at 60 °C for 6 hours, filter, wash the filter cake several times, dry at 70 °C for 12 hours, and finally grind , that is, a polyethyleneimine-modified calcium aluminum lanthanum hydrotalcite (6%-PEI-CaAlLa-LDH) composite material is obtained.

[0034] When the intermediate reaction solution was stirred, the stirrin...

Embodiment 2

[0037] Preparation of 7%-PEI-CaAlLa-LDH:

[0038] At room temperature, 4.44g CaCl 2 , 1.07g AlCl 3 and 0.87g La (NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of deionized water to form a mixed salt solution, and then a polyethyleneimine solution with a concentration of 7 wt% was slowly added to the mixed salt solution to form an imine salt mixed solution. Take 0.6mol / L Na 2 CO 3 The solution was added dropwise to the imide salt mixed solution at a speed of 6 mL / min, and the reaction was carried out to obtain an intermediate reaction solution.

[0039] Keep stirring the intermediate reaction solution until the pH of the intermediate reaction solution = 8, then age at 70 °C for 7 hours, filter, wash the filter cake several times, dry at 70 °C for 16 hours, and finally grind , that is, a polyethyleneimine-modified calcium aluminum lanthanum hydrotalcite (7%-PEI-CaAlLa-LDH) composite material is obtained.

[0040] When the intermediate reaction solution was stirred, the stirri...

Embodiment 3

[0042] Preparation of 8%-PEI-CaAlLa-LDH:

[0043] At room temperature, 4.44g CaCl 2 , 1.07g AlCl 3 , 0.87g La (NO 3 ) 3 ·6H 2 O was dissolved in 100 mL of deionized water to form a mixed salt solution, and then the polyethyleneimine solution with a concentration of 8wt% was slowly added to the mixed salt solution to form an imide salt mixed solution. Take 0.7mol / L Na 2 CO 3 The solution was added dropwise to the imide salt mixed solution at a speed of 7 mL / min, and the reaction was carried out to obtain an intermediate reaction solution.

[0044] Keep stirring the intermediate reaction solution until the pH of the intermediate reaction solution = 9, then age at 80°C for 10h, filter, wash the filter cake several times, dry at 80°C for 20h, and finally grind it , that is, a polyethyleneimine-modified calcium aluminum lanthanum hydrotalcite (8%-PEI-CaAlLa-LDH) composite material is obtained.

[0045] When the intermediate reaction solution was stirred, the stirring time w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com