Garment processing excess material recovery device

A recovery device and residual material technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of crushing device damage, screen blockage, small stones, etc., and achieve the effect of high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

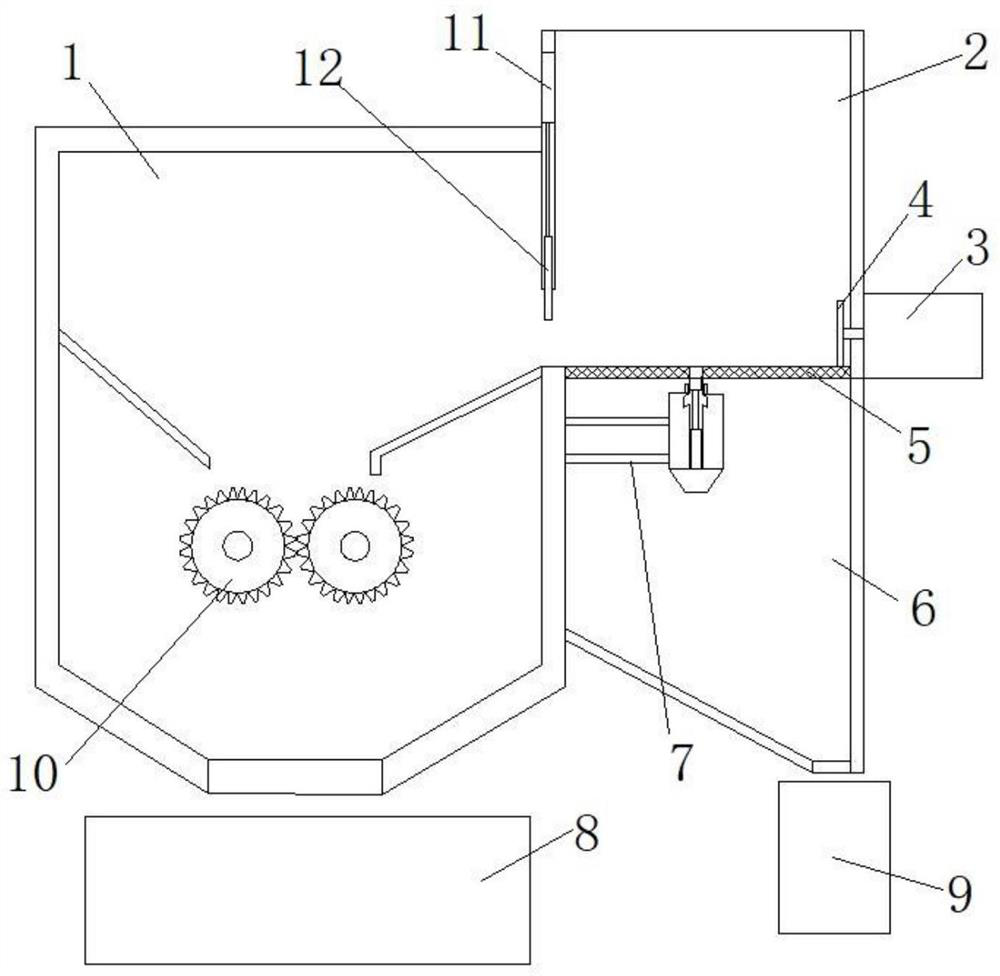

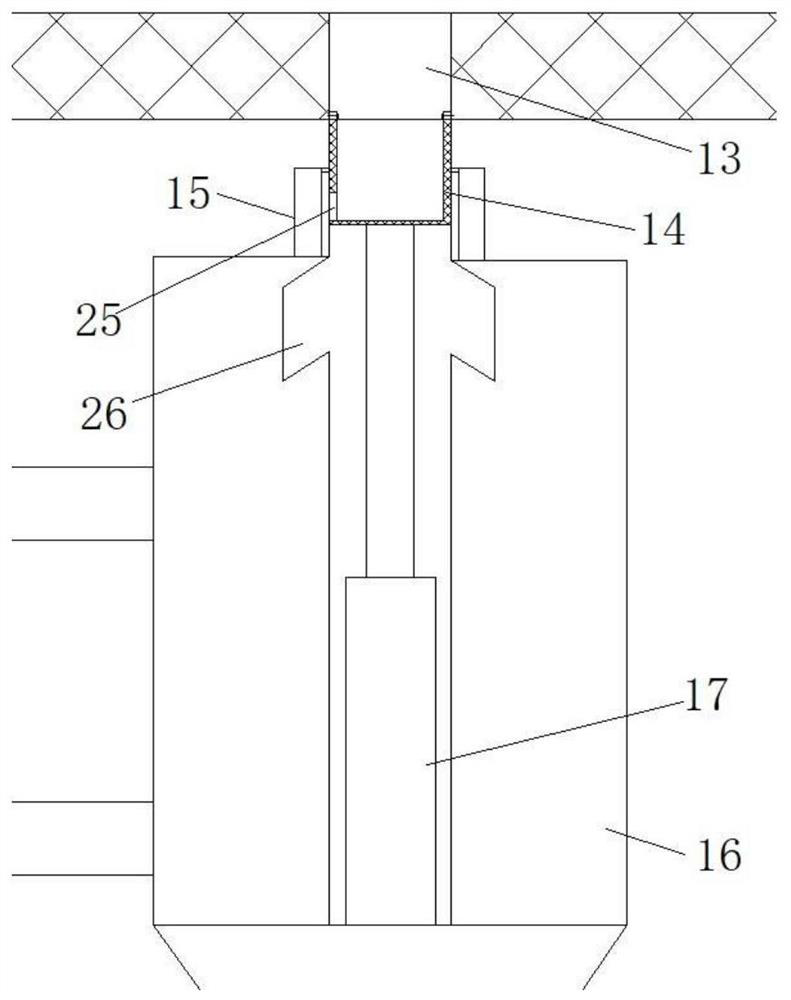

[0029] like Figure 1 to Figure 3 As shown, the screening mechanism includes a screening buffer box 2, a screen cloth 5 located at the bottom of the screening buffer case 2, and a particle separation mechanism located below the screen cloth 5. The feed port of 1 is connected, and the middle part of the screen 5 is provided with a through hole 13, and the particle separation mechanism drives the screen 5 to move downward to guide the collected impurity particles downward through the through hole 13. Among them, the aperture of the through hole is larger than the aperture of the screen. Since the screen has elastic deformation force, the particle separation mechanism drives the screen to move downward, and the relatively large particles will gather at the through hole in the middle of the screen, which is relatively convenient. Large particles of impurities are screened out through the through holes.

[0030] The particle separation mechanism comprises a separation box 16, a bu...

Embodiment 2

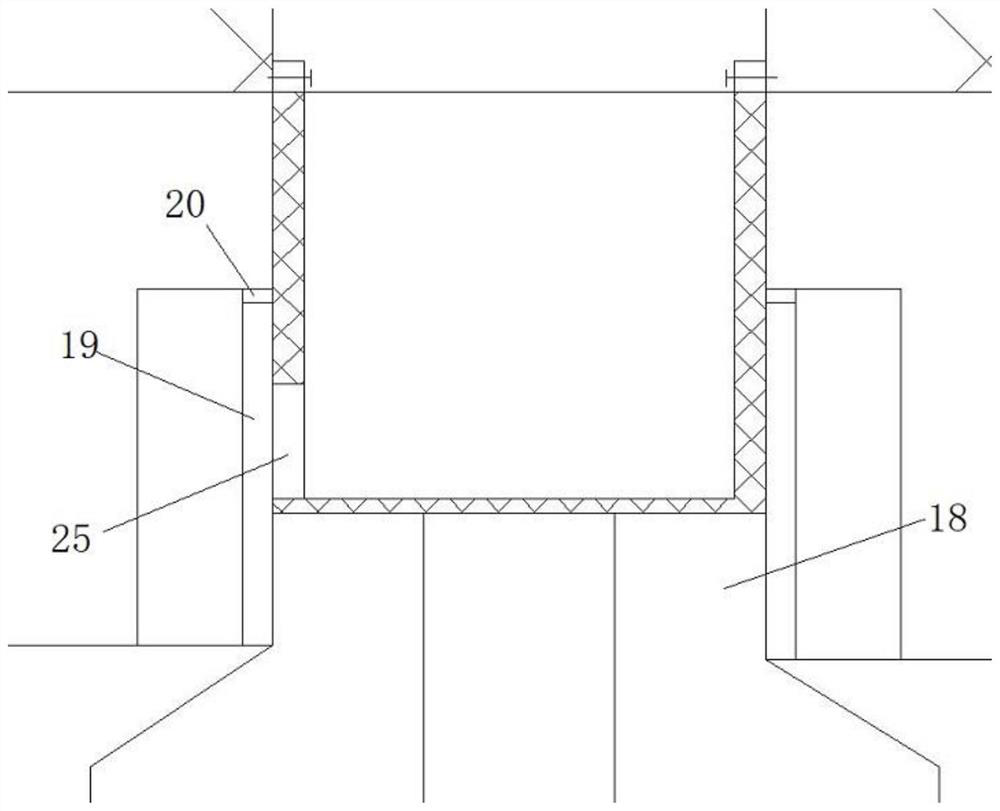

[0038] The difference between this embodiment and embodiment 1 is that, as Figure 4 and Figure 5 As shown, the lifting mechanism includes a drive motor 21, a rack 22 disposed in the cavity, and a gear 23 meshed with the rack 22. The gear 23 is installed in the cavity by rotating a shaft 24. The output of the drive motor 21 The end is connected with the rotating shaft 24, and the driving motor 21 rotates through the driving gear 23 so that the rack 22 drives the shielding plate 12 to move up and down. When setting, the gear is connected with the bearing on the inner wall of the cavity through one end of the rotating shaft, and the other end of the rotating shaft is connected with the output shaft of the driving motor through a coupling. When needing to open and close the feeding port of the pulverizing hopper, start the driving motor 21, the driving motor drives the gear to rotate, the gear drives the rack to move up and down in the cavity, and the rack drives the baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com