Hot continuous rolling production method for 530-mm large-diameter seamless steel pipe

A technology for seamless steel pipes and production methods, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as short service life, increased production costs, and excessive pipe diameters, so as to reduce production costs and improve Production efficiency, effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Prepare a steel pipe with an outer diameter of 530 mm and a thickness of 12 mm, which belongs to the extreme thin-walled pipe (D / S=44.17).

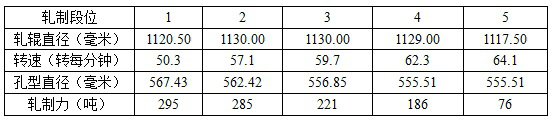

[0048] The steel grade of the billet is No. 20 steel. The temperature of the billet out of the annular heating furnace is 1280 degrees Celsius. The annular heating furnace is divided into 7 sections for heating, which are respectively: 900 degrees Celsius, 1100 degrees Celsius, 1220 degrees Celsius, 1250 degrees Celsius, 1310 degrees Celsius. degrees Celsius, 1290 degrees Celsius and 1280 degrees Celsius; when the billet is pierced, the diameter of the mandrel is 527 mm, and the capillary size after piercing is 606 mm in outer diameter and 27 mm in thickness. figure 1 As shown; the size of the blank tube after continuous rolling is 554 mm in outer diameter, 11.94 mm in thickness, and the elongation coefficient is 9.45; there are 5 racks in total for the tube removal rack and the sizing rack, of which there are 3 racks for the tube r...

Embodiment 2

[0050] Prepare a steel pipe with an outer diameter of 530 mm and a thickness of 24 mm, which is a thin-walled pipe (D / S=22.08).

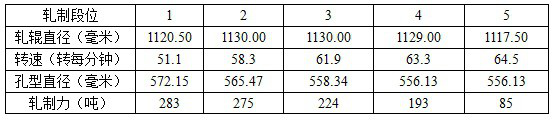

[0051] The steel grade of the billet is No. 20 steel. The temperature of the billet out of the annular heating furnace is 1270 degrees Celsius. The annular heating furnace is divided into 7 sections for heating, which are respectively: 900 degrees Celsius, 1100 degrees Celsius, 1220 degrees Celsius, 1250 degrees Celsius, 1310 degrees Celsius. degrees Celsius, 1280 degrees Celsius and 1270 degrees Celsius; the size of the perforated capillary tube is 606 mm in outer diameter and 36 mm in thickness. figure 2 As shown; the size of the waste tube after continuous rolling is 554 mm in outer diameter and 23.92 mm in thickness, and there are 5 de-pipe racks in total, of which 3 are de-pipe racks, and the minimum 2B value of the de-pipe rack (pass type Size) is 540 mm, and the finished product size after sizing the frame is 508 mm in outer diameter and 24 ...

Embodiment 3

[0053] Prepare a steel pipe with an outer diameter of 530 mm and a thickness of 36 mm, which belongs to thick-walled pipes (D / S=14.72).

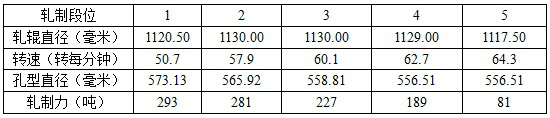

[0054] The steel grade of the billet is No. 20 steel. The temperature of the billet out of the annular heating furnace is 1260 degrees Celsius. The annular heating furnace is divided into 7 sections for heating, which are respectively: 900 degrees Celsius, 1100 degrees Celsius, 1220 degrees Celsius, 1240 degrees Celsius, 1300 degrees Celsius. degrees Celsius, 1270 degrees Celsius and 1260 degrees Celsius; the size of the perforated capillary tube is 606 mm in outer diameter and 47 mm in thickness. image 3 As shown; the size of the waste tube after continuous rolling is 530 mm in outer diameter and 35.92 mm in thickness, and there are 3 racks in total, of which there are 3 racks, and the smallest rack 2B value (pass type Size) is 540 mm, and the finished product size after sizing the frame is 530 mm in outer diameter and 36 mm in thickness. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com