Process method device for producing stained glass by continuous casting

A technology of stained glass and process method, which is applied in the field of architectural decoration, can solve the problem that the stained glass products with layers and natural textures cannot be produced, the stirring process cannot be performed in deep glass liquid, and the amount of single-color glass liquid is difficult to adjust and control, etc. problems, to achieve the effect of expanding production capacity, simple structure, and improving glass flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

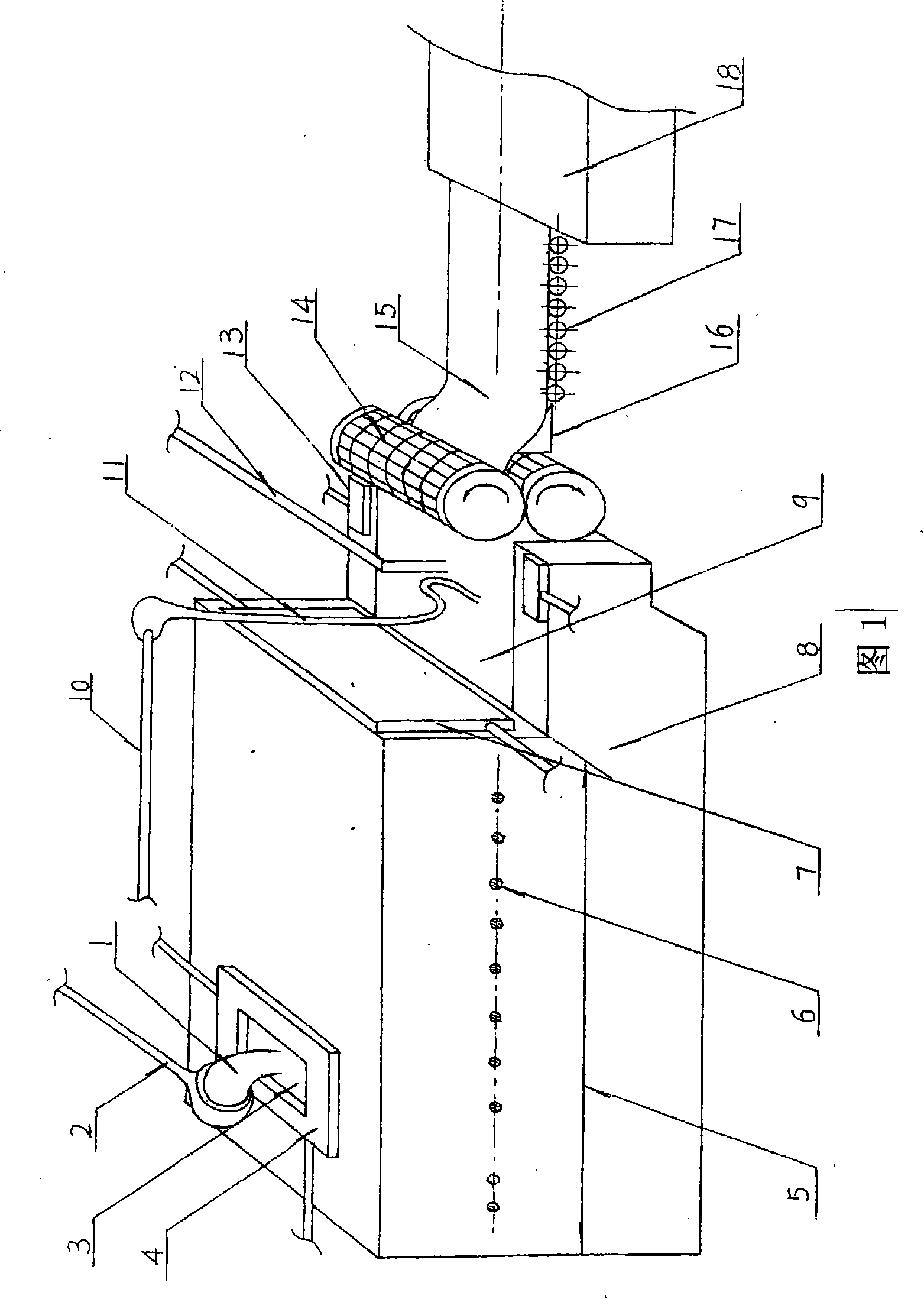

[0024] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0025] The present invention specifically produces a kind of colored drawing plate glass that base material is colorless glass, color material is three kinds of glasses of red, green, blue, and product length 1200mm, width 710mm, thickness 5mm.

[0026]The glass base material and colorant are melted in the crucible kiln, and the process flow is shown in Figure 1. The melted base material [1] is manually dug out from the crucible kiln with a steel spoon [2], sent to the material inlet [3] of the coloring channel [8], poured into the storage pool [5] , the lower part of the pool is a narrow and long material storage channel made of electro-fused refractory masonry, and the width of the rear part gradually expands in a trumpet shape to connect with the stirring pool [9]. The space above the storage tank is equipped with a silicon carbide rod electric heating eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com