A kind of three-dimensional weaving processing equipment and its application method for dynamically intercepting PM2.5 three-dimensional knitted fabric

A PM2.5, three-dimensional knitting technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of single function and lack of equipment for three-dimensional knitwear, and achieve simple equipment structure, low cost, and strong reliability. controlling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

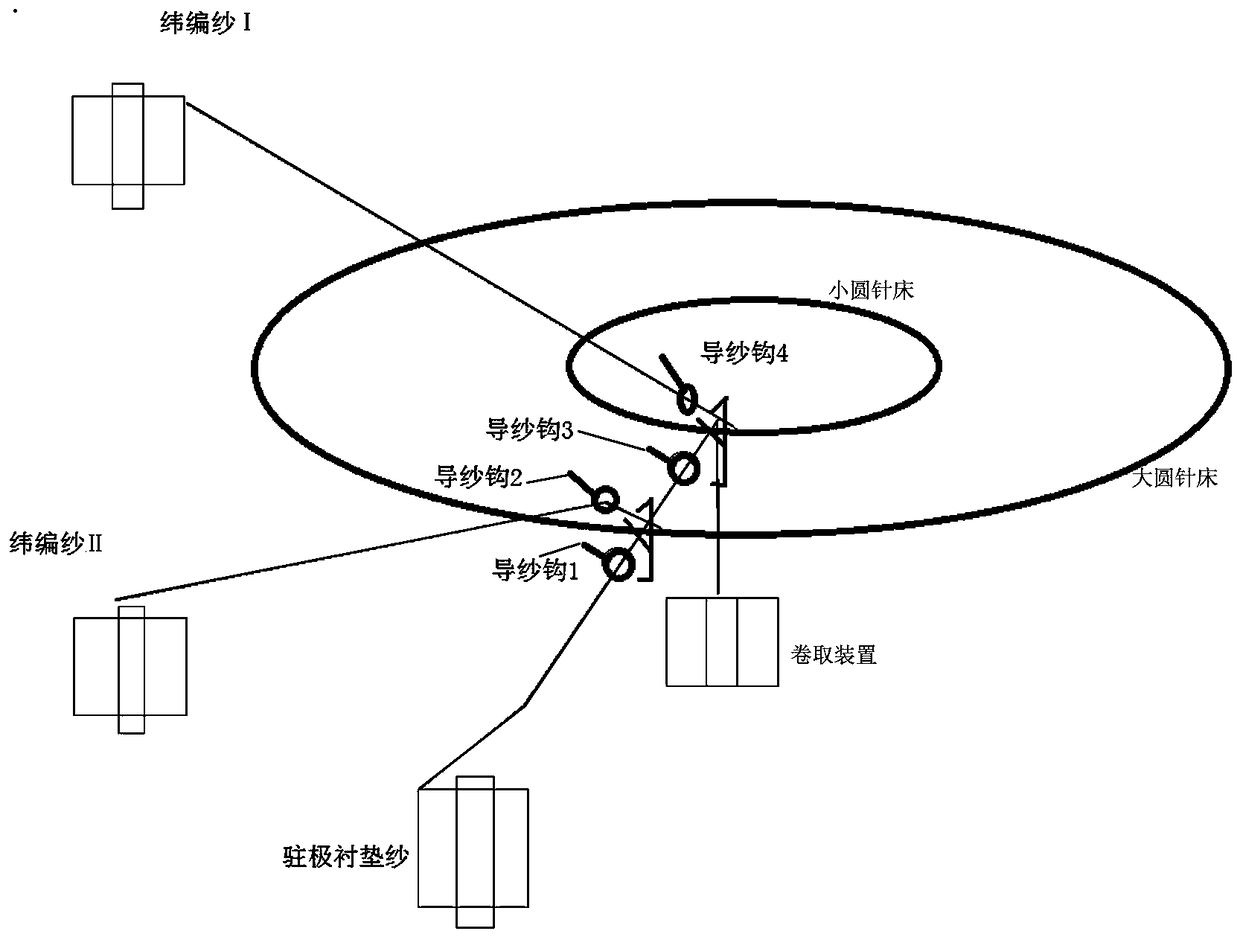

[0038] Three-dimensional knitting dynamic intercept PM2.5 three-dimensional knitted fabric processing equipment, including double circular needle bed device controlled by servo motor, yarn guide hook device, yarn supply device corresponding to the needle bed and three-dimensional fabric roll under the double circular needle bed device The take-up device, wherein the diameter of the small round needle bed is 10 cm, the diameter of the large round needle bed is 30 cm, the vertical height difference of the flat top surface of the large and small round needle beds is 5 cm, and the yarn supply device includes weft knitting yarn I, weft knitting yarn II and poly four For the electret fiber made of vinyl fluoride, the yarn guide hook device includes yarn guide hook I, yarn guide hook II, yarn guide hook III and yarn guide hook IV, and there are 16 sets of yarn supply device and yarn guide hook device respectively.

[0039] The 16 sets of weft knitting yarns Ⅰ and 16 sets of weft knitt...

Embodiment 2

[0041] Three-dimensional knitting dynamic intercept PM2.5 three-dimensional knitted fabric processing equipment, including double circular needle bed device controlled by servo motor, yarn guide hook device, yarn supply device corresponding to the needle bed and three-dimensional fabric roll under the double circular needle bed device The take-up device, wherein the diameter of the small round needle bed is 5 cm, the diameter of the large round needle bed is 25 cm, the vertical height difference of the flat top surface of the large and small round needle beds is 10 cm, and the yarn supply device includes weft knitting yarn I, weft knitting yarn II and poly-biasing For the electret fiber made of vinyl fluoride, the yarn guide hook device includes yarn guide hook I, yarn guide hook II, yarn guide hook III and yarn guide hook IV, and there are 10 sets of yarn supply device and yarn guide hook device respectively.

[0042] The 10 weft knitting yarns corresponding to the needle bed ...

Embodiment 3

[0044] Three-dimensional knitting dynamic intercept PM2.5 three-dimensional knitted fabric processing equipment, including double circular needle bed device controlled by servo motor, yarn guide hook device, yarn supply device corresponding to the needle bed and three-dimensional fabric roll under the double circular needle bed device The take-up device, wherein the diameter of the small round needle bed is 15 cm, the diameter of the large round needle bed is 20 cm, the vertical height difference of the flat top surface of the big and small round needle beds is 15 cm, and the yarn supply device includes weft knitting yarn I, weft knitting yarn II and polypropylene The produced electret fiber, the yarn guide hook device includes yarn guide hook I, yarn guide hook II, yarn guide hook III and yarn guide hook IV, and the yarn supply device and the yarn guide hook device are respectively provided with 32 groups.

[0045] The 32 sets of weft knitting yarns Ⅰ and 32 sets of weft knitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com