Stereoscopic silk imitation fur plus material

A technology of imitating fur and silk, applied in the field of textiles, can solve the problems of reducing the impact of silk appearance, consumer purchases, not having a three-dimensional effect, and increasing the cost of silk, etc., to achieve a wide range of product use, good three-dimensional structure and pattern effect , The effect of strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

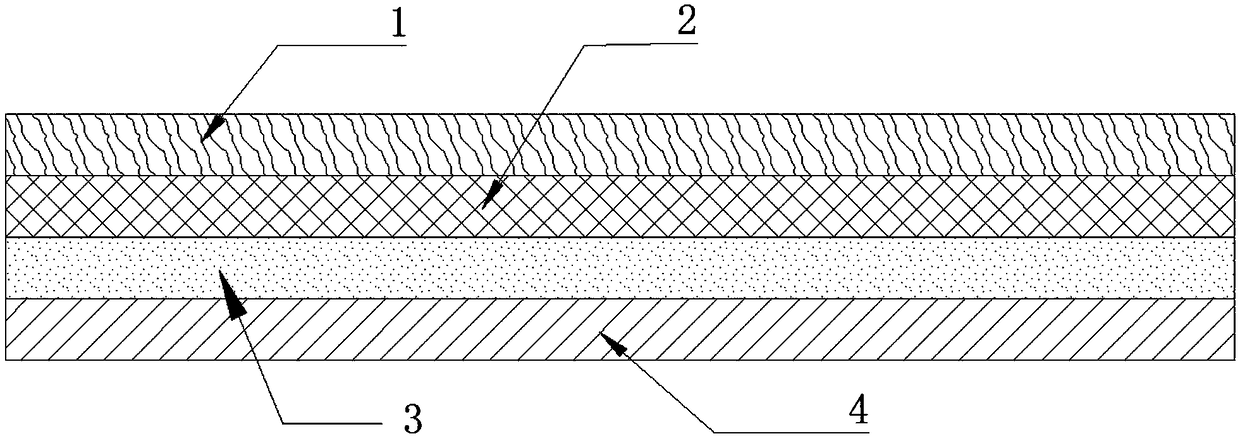

[0038] Such as figure 1 Shown, a kind of three-dimensional silk imitation fur fabric, comprises real silk fluff layer 1, rayon base layer 2, adhesive layer 3 and imitation leather fleece layer 4, and described real silk fluff layer 1 is combined with described rayon base layer by knitting 1, the rayon base layer 2 and the leather-like suede layer 4 are bonded through the adhesive layer 3. Wherein, the adhesive layer is a thermosetting adhesive layer.

[0039] The silk fluff layer 1 uses mulberry silk as fluff raw material; the rayon base layer 2 uses rayon as a raw material, and the real silk fluff layer 1 and the rayon base layer 2 are formed by circular knitting, specifically comprising the following steps:

[0040] (1a) Using mulberry silk as the fluff raw material, using rayon as the base layer raw material, putting mulberry silk and rayon on the large circular knitting machine;

[0041](2a) The large circular knitting machine reuses the yarn to form a coil, which is for...

Embodiment 2

[0053] A kind of three-dimensional silk fur-like fabric, comprising a real silk fluff layer 1, an artificial silk base layer 2, an adhesive layer 3 and an imitation leather fleece layer 4, and the real silk fluff layer 1 is knit with the top of the artificial silk base layer 1 Fixedly connected, the rayon base layer 2 and the leather-like suede layer 4 are bonded through the adhesive layer 3 . Wherein, the adhesive layer is a thermosetting adhesive layer.

[0054] The preparation method of the mulberry silk is the same as in Example 1. The fineness of the mulberry silk is 50D; the length of the mulberry silk is 10mm.

[0055] Before the mulberry silk and rayon are spun, the mulberry silk and rayon are also subjected to antibacterial modification treatment, which specifically includes the following steps:

[0056] (1d) adding rhubarb into ethanol solution according to the mass ratio of 1:20 after crushing rhubarb, extracting at 65-70° C. for 2-3 hours, centrifuging, and conce...

Embodiment 3

[0064] A kind of three-dimensional silk fur-like fabric, comprising a real silk fluff layer 1, an artificial silk base layer 2, an adhesive layer 3 and an imitation leather fleece layer 4, and the real silk fluff layer 1 is knit with the top of the artificial silk base layer 1 Fixedly connected, the rayon base layer 2 and the leather-like suede layer 4 are bonded through the adhesive layer 3 . Wherein, the adhesive layer is a thermosetting adhesive layer.

[0065] The preparation method of the mulberry silk is the same as in Example 1. The fineness of the mulberry silk is 100D; the length of the mulberry silk is 20mm

[0066] Before the mulberry silk and rayon are weaved, the mulberry silk and rayon are subjected to antibacterial modification treatment, which specifically includes the following steps:

[0067] (1d) adding rhubarb into ethanol solution according to the mass ratio of 1:15 after crushing rhubarb, extracting at 65-70° C. for 2-3 hours, centrifuging, and concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com