A method for simulating the motion path of a manipulator

A simulation method and motion path technology, applied in the field of manipulators, can solve problems such as workpiece damage and machining parts collision, and achieve the effect of ensuring integrity, ensuring safety, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

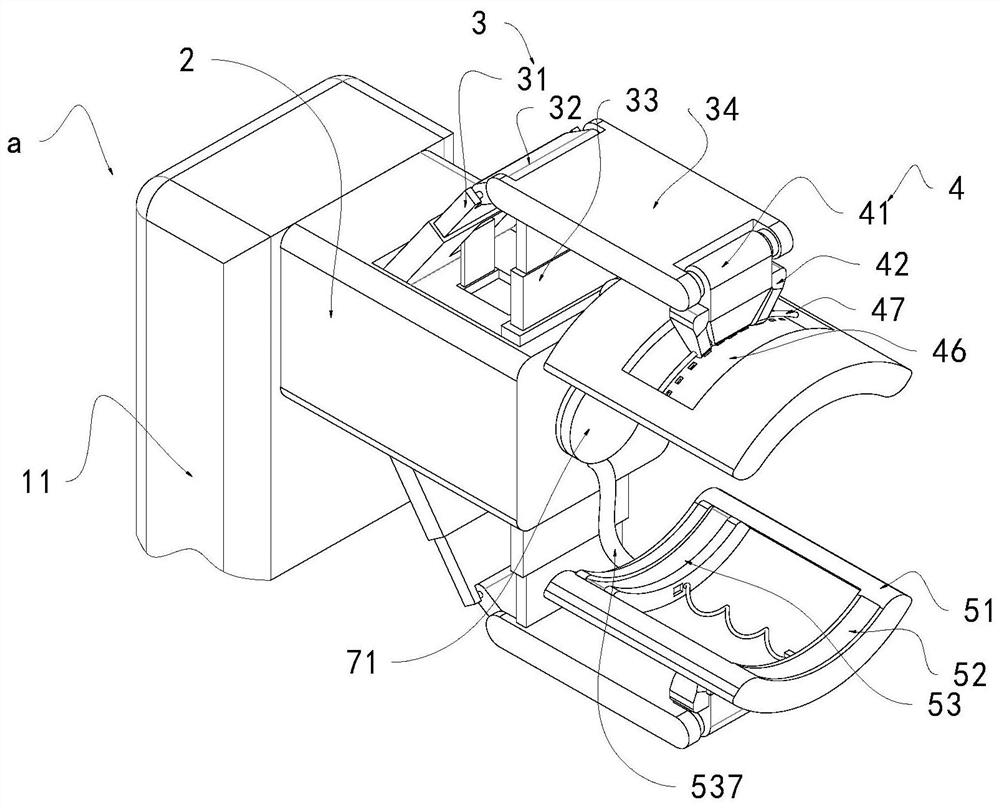

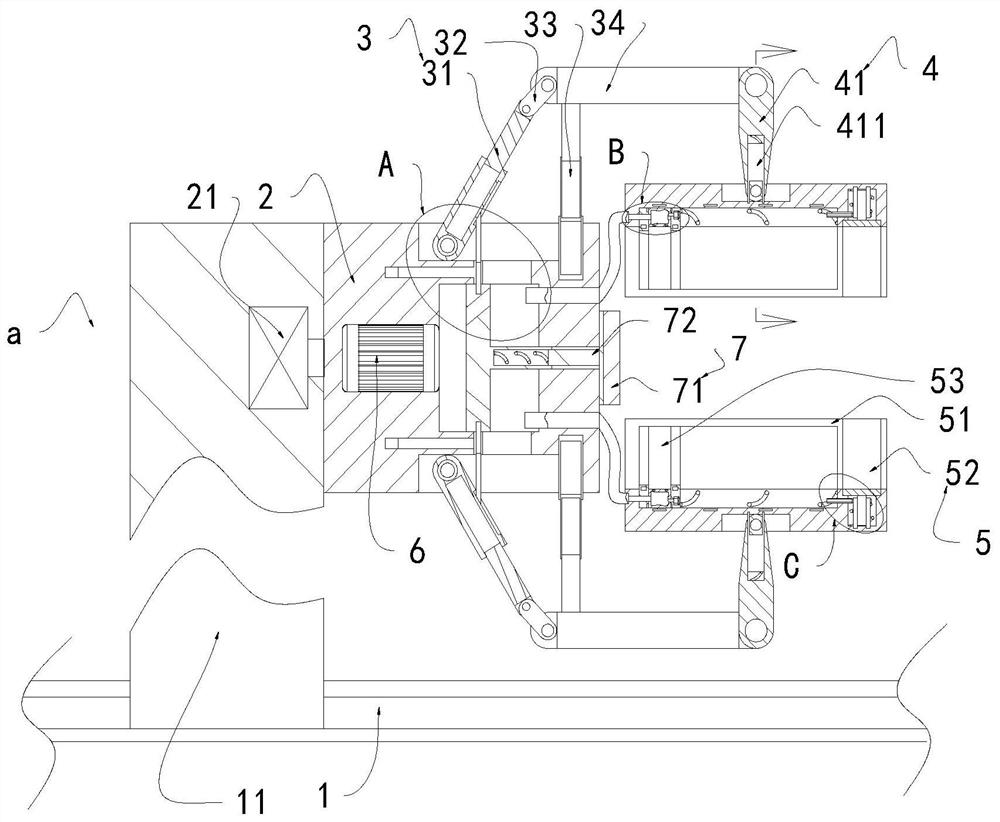

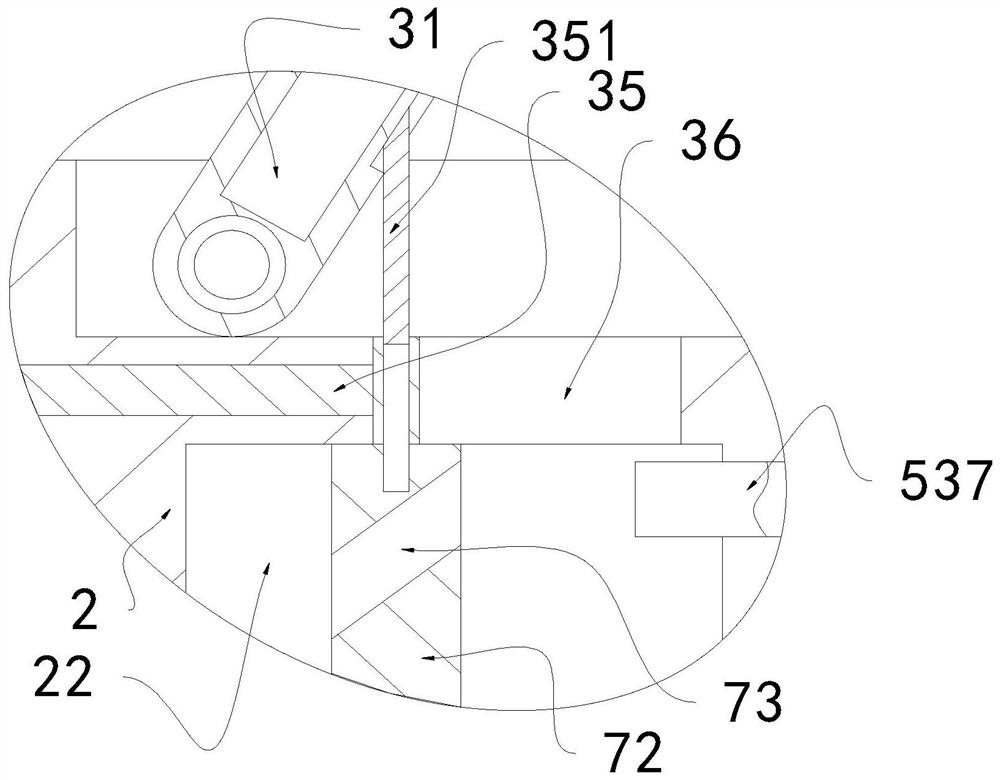

[0034] see Figure 1-8 A method for simulating the motion path of a manipulator, the steps are as follows:

[0035] The first step is to move the manipulator a to the position of the double-spindle machining center, and lay the working track 1 on the moving path of the manipulator a, so that the central control system can establish the coordinate system of the workpiece position and the coordinate system of the manipulator a in the same coordinate system Next, to determine the specific spatial position of the manipulator a in the coordinate system;

[0036] The second step is to obtain the initial mathematical model of the unprocessed workpiece surface, denoted as b1, and at the same time retrieve the programmed workpiece surface shape on the dual-spindle machining center, and perform mathematical modeling on it, denoted as the programmed workpiece surface mathematical model b2 , through b2 to determine the specific position coordinates of the workpiece after machining in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com