A water-stabilized crushed stone grading method with large differences in aggregate density

A water-stabilized gravel, high-density technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as large volume, not meeting the needs of sustainable ecological development, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

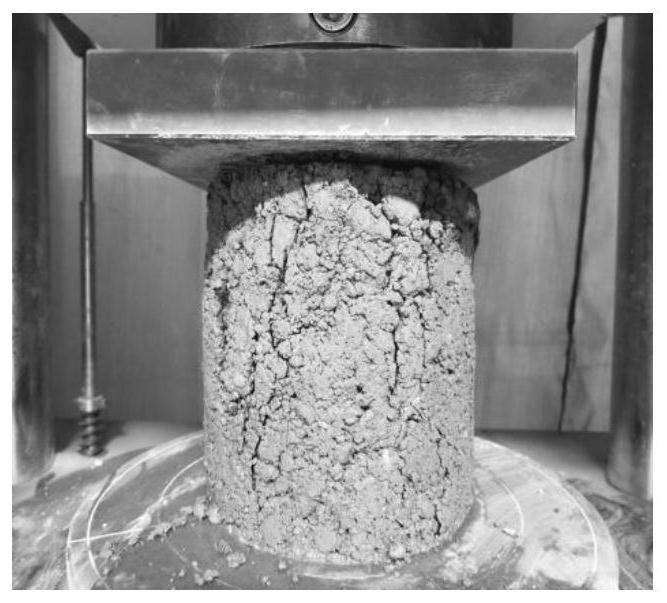

Image

Examples

Embodiment Construction

[0022] The following will describe in detail a water-stabilized crushed stone grading method with large differences in aggregate density of the present invention through specific examples.

[0023] The recommended grading range (CF-B-2S) of the base cement and fly ash stabilized crushed stone provided by Table 4.5.7 in the specification "Highway Pavement Base Construction Technical Specifications" (JTG / T F20-2015), hereinafter collectively referred to as "" Standard", the upper and lower limits of the sieve quality of each grade of sieve are shown in Table 1 (converted from the cumulative sieve of each grade to the sieve of each grade of sieve quality).

[0024] Table 1 Recommended quality sieve residue for cement fly ash stabilized graded crushed stone

[0025]

[0026] Concrete recycled crushed stone is selected as the main aggregate and recycled brick as the auxiliary aggregate, and the density of the brick is 0.992g / cm 3 , the density of recycled concrete is 1.58g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com