Automatic screwing-on and screwing-off device of sucker rod for oil field

A sucker rod, automatic technology, applied in drill pipes, drilling equipment, earthwork drilling, etc., can solve the problems of deflection of sucker rod shackle, many tools for making and breaking, and low efficiency, so as to avoid loosening and strengthen Assembly effect, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

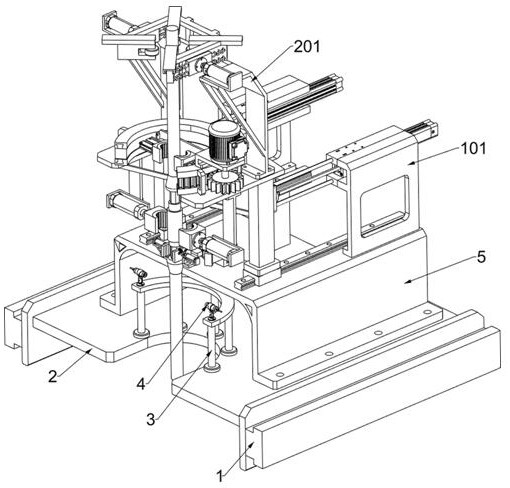

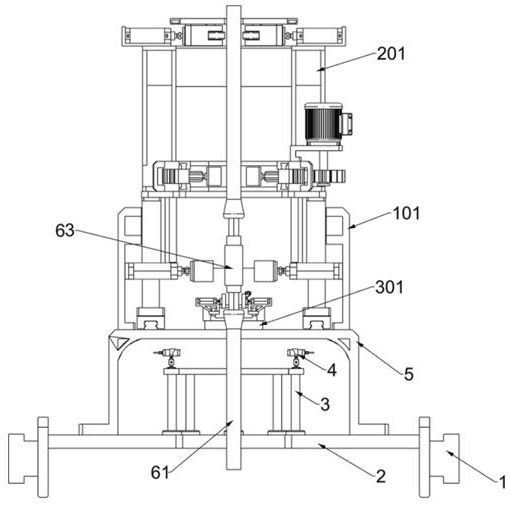

[0030] An automatic screw-on and break-out device for a sucker rod used in an oil field, such as Figure 1-3 As shown, it includes a guide mounting plate 1, a working base plate 2, a second support frame 5, a clamping and twisting system, a positive position system and an adaptive clamping system; the opposite sides of the two guide mounting plates 1 are connected with a working base plate 2; The upper surface of the working base plate 2 is connected with the second support frame 5; the upper surface of the second support frame 5 is connected with the clamping knob system; the upper part of the clamping knob system is connected with the positive positioning system; There is an adaptive snap-in system.

[0031] The left part of the working base plate 2 has a U-shaped groove.

[0032] It also includes a first support frame 3 and a monitoring positioning member 4; the upper surface of the working base 2 is fixed with the first support frame 3; the upper surface of the first supp...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and Figure 4-6 As shown, the clamping knob system includes a first support plate 101, a first electric telescopic member 102, a third support frame 103, a support slider 104, a first straight slide rail 105, a second support plate 106, a second electric Telescopic piece 107, first arc-shaped clamp 108, arc-shaped slide rail 109, gear ring 1010, first fixed plate 1011, third electric telescopic piece 1012, second arc-shaped clamp 1013, third support plate 1014, motor 1015 and flat Gear 1016; the upper surface of the second support frame 5 is fixed with two symmetrical and parallel first support plates 101; each of the two first support plates 101 is connected with a first electric telescopic member 102 by bolts; two first electric telescopic members 102, the telescopic part is fixedly connected with a third support frame 103; the bottom of the third support frame 103 is welded with two symmetrical support sliders 104; the upp...

Embodiment 3

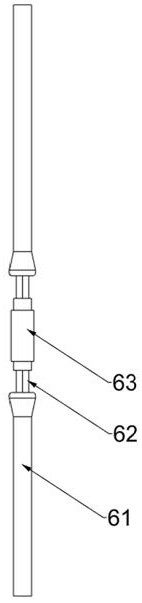

[0042] On the basis of Example 2, such as Figure 10 As shown, the adaptive clamping system includes a sixth support frame 301, an electric slide rail 302, an electric slider 303, a third fixed plate 304, a seventh support frame 305, a fifth electric telescopic member 306, straight-nose pliers 307, Fixed frame 308 and distance measurer 309; The left part of the upper surface of the second support frame 5 is fixedly connected with the sixth support frame 301; The left part of the sixth support frame 301 is fixedly connected with the electric slide rail 302; Electric slider 303; a third fixed plate 304 is fixedly connected to the electric slider 303; two symmetrical seventh support frames 305 are welded on the third fixed plate 304; each of the two seventh support frames 305 is fixed with a The fifth electric telescopic part 306; each of the telescopic parts of the two fifth electric telescopic parts 306 is fixedly connected with a straight-nose pliers 307; Each is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com