Pre-empty soft rock tunnel supporting structure and construction method thereof

A technology for roadway support and roadway, which is applied to the support structure of pre-empty soft rock roadway and its construction field, can solve problems such as failure to achieve supporting effect, stress concentration, accelerated roadway damage, etc., so as to reduce the difficulty of laying and improve the support Strength, the effect of improving support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

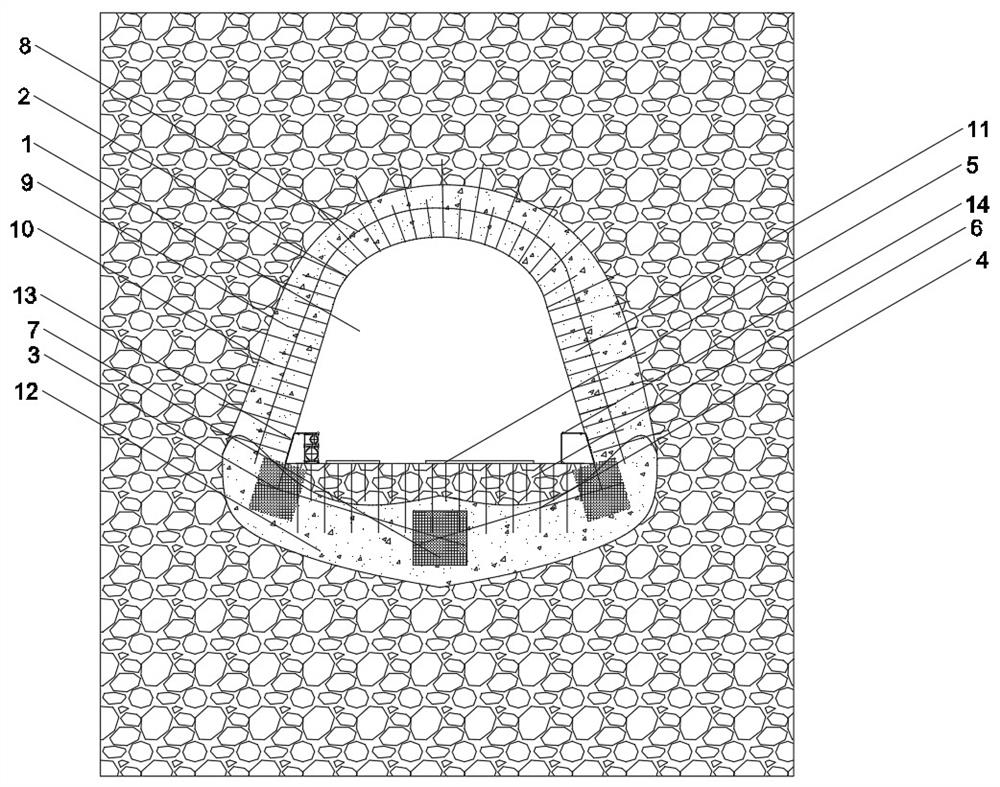

[0035] The steel arch (2) is a track steel structure; compared with the I-shaped steel structure, the support strength of the track steel is higher.

[0036] The number of the V-shaped frame (4) is the same as that of the steel arch frame (2). The V-shaped frame (4) is composed of two intersecting vertical steel materials. The intersection of the two intersecting vertical steel materials is It is the middle end of the V-shaped frame (4); the V-shaped frame (4) can be simultaneously subjected to the pressure from below and the external tension generated by the steel arch (2) caused by the downward pressure of the roof of the roadway, limiting the steel arch (2) The bottom corners move outward.

Embodiment 3

[0038] Both ends of the V-shaped frame (4) are welded to connect the bottom corners of the steel arch (2), and two steel materials in the V-shaped frame (4) are welded and connected.

Embodiment 4

[0040] The two ends of the V-shaped frame (4) are fixedly connected to the bottom corners of the steel arch frame (2) by bolts, and the two steel materials in the V-shaped frame (4) are fixedly connected to each other by bolts; welding / bolts can increase the steel The connection strength of the arch frame (2) and the V-shaped frame (4), thereby enhancing the support strength of the roadway (1).

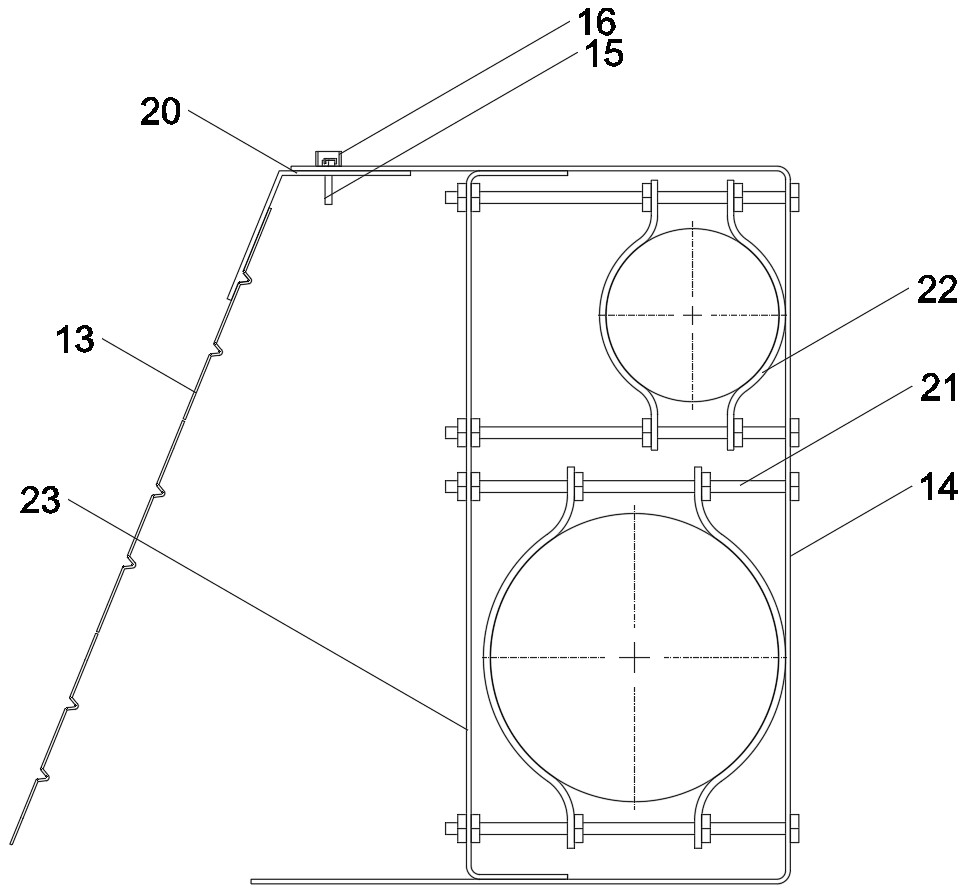

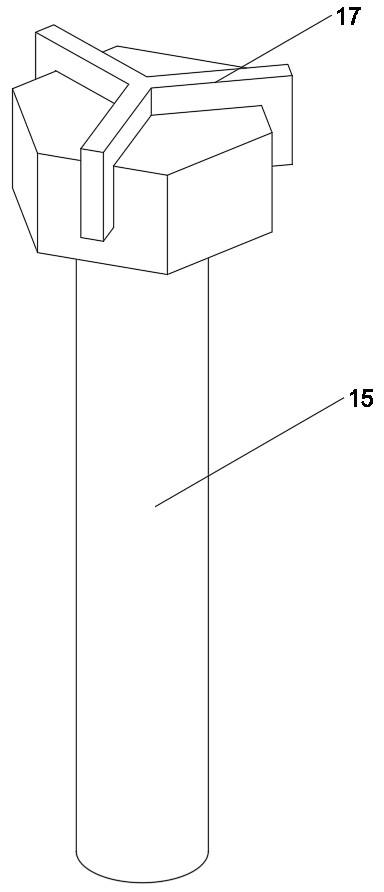

[0041] The connecting plate (13) is composed of a plurality of W-shaped steel strips installed in equal intervals along the side walls of the roadway. The longitudinal section of the clamping plate (20) is a V-shaped structure, and one end of the clamping plate (20) The side of the side is fixed with a bump structure that is fitted in the groove of the connecting plate (13); on the one hand, the connecting plate (13) composed of multiple W-shaped steel strips can improve the support strength of the side wall, and on the other hand On the other hand, multiple prestressed anchor rods (9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com