Quick resetting system for machine table

A fast and machine-based technology, applied in the direction of fluid pressure actuation system components, presses, mechanical equipment, etc., can solve problems such as affecting the rising speed and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

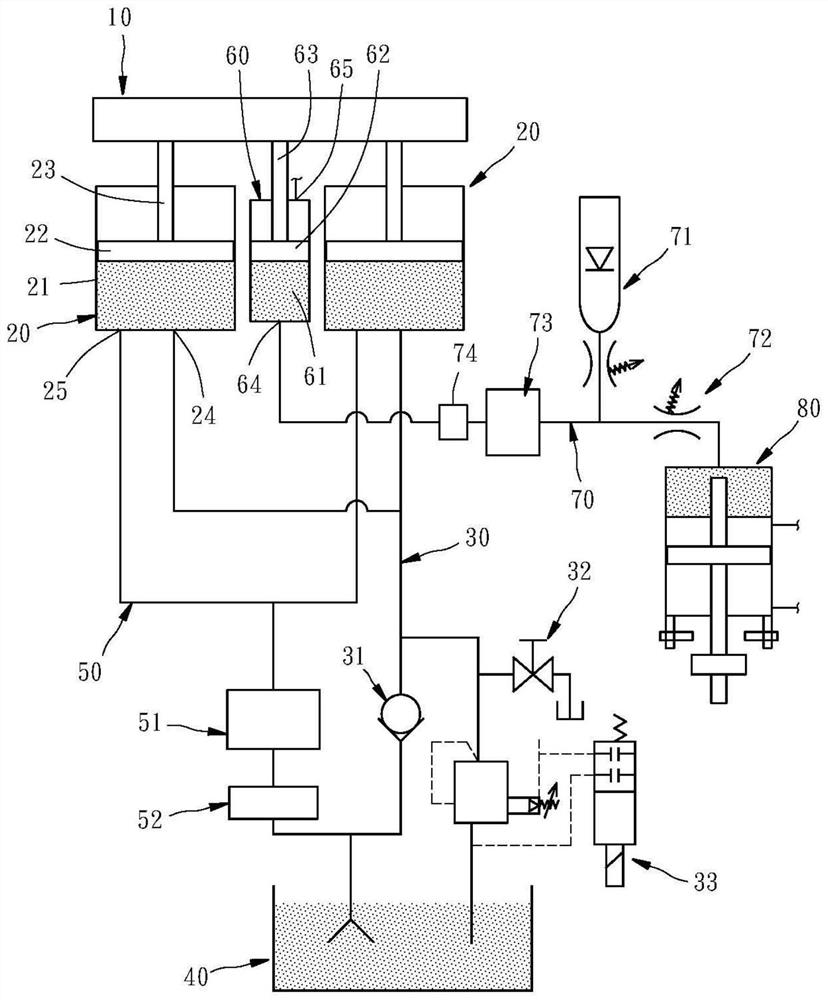

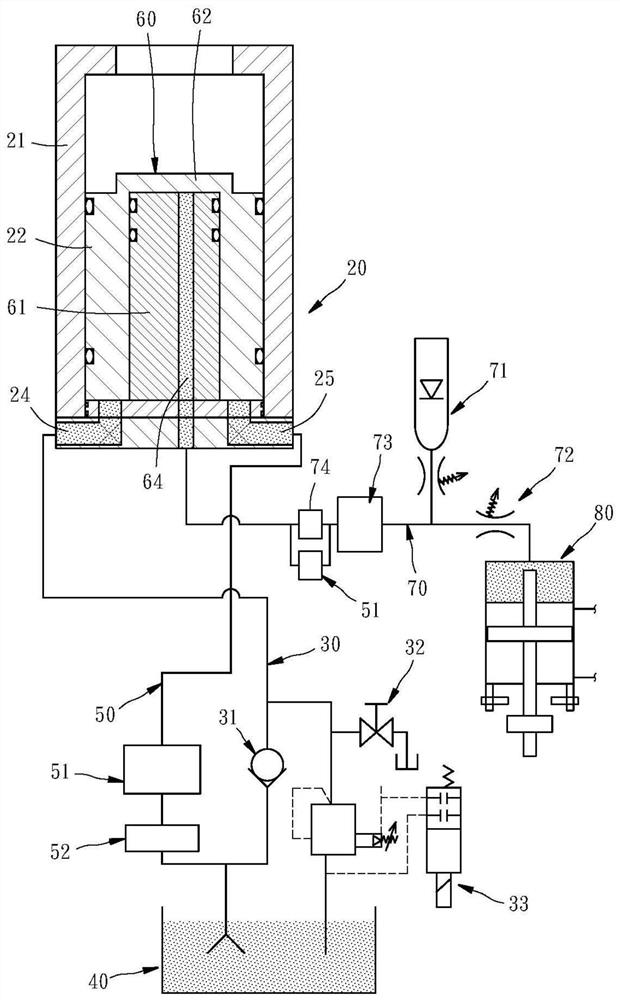

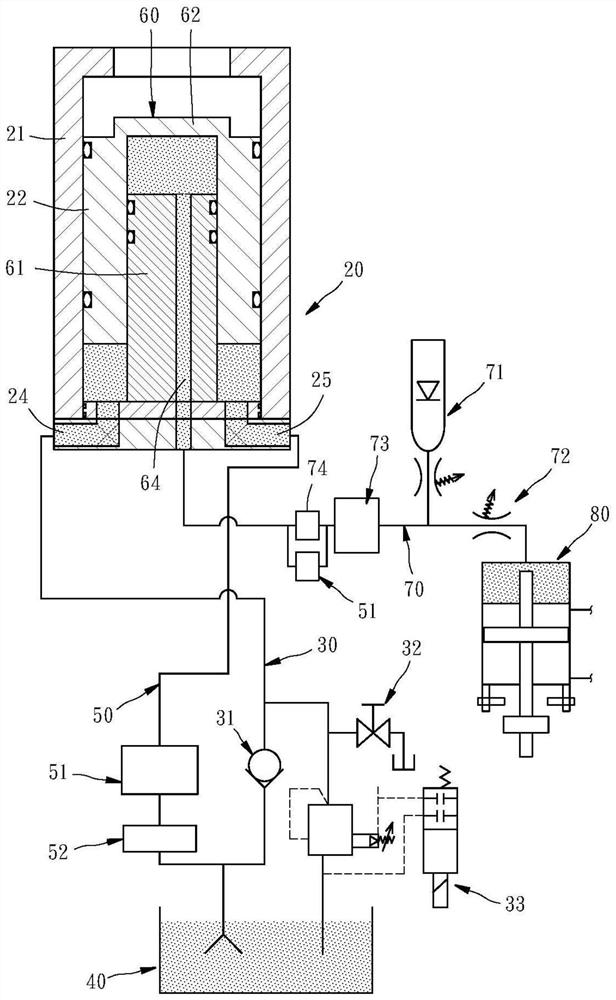

[0023] Such as figure 1 As shown, a machine rapid return system provided by a preferred embodiment of the present invention, such as for punch presses, etc., includes:

[0024] A movable platform 10 is located at a predetermined position of the machine platform.

[0025] A pair of buffer cylinders 20 each have a buffer cylinder 21, a buffer piston 22, and a buffer rod 23 connected to the buffer piston 22 and the movable table 10; each buffer cylinder 21 has an oil suction hole 24 and an oil discharge hole 25.

[0026] An oil suction pipeline 30 connects the oil suction holes 24 of the pair of buffer cylinders 20 with an oil tank 40 , and can absorb oil into the buffer piston 22 of the buffer cylinders 20 .

[0027] In this embodiment, the oil suction line 30 has a one-way valve 31 .

[0028] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com