Transition roller table bearing mounting plate and machining method thereof

A transition roller and mounting plate technology, which is applied in the direction of bearing cooling, bearing components, shafts and bearings, etc., can solve the problems of inaccurate positioning, difficult splicing of transition roller table bearing mounting plates, large welding deformation, etc., to achieve convenient processing and solve Difficult splicing and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

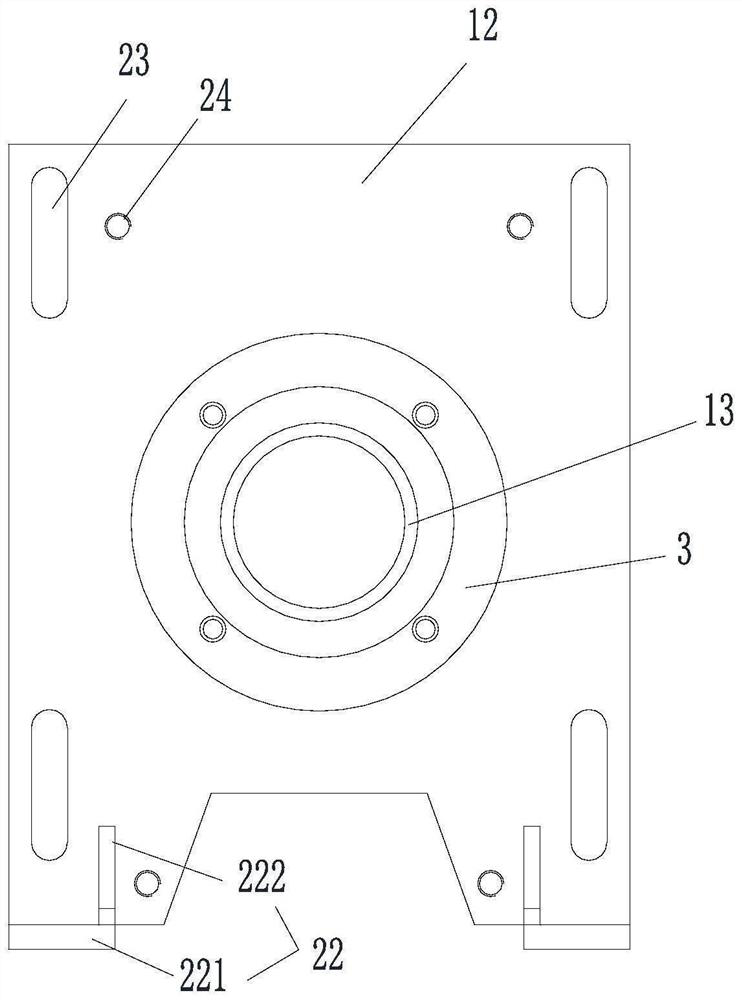

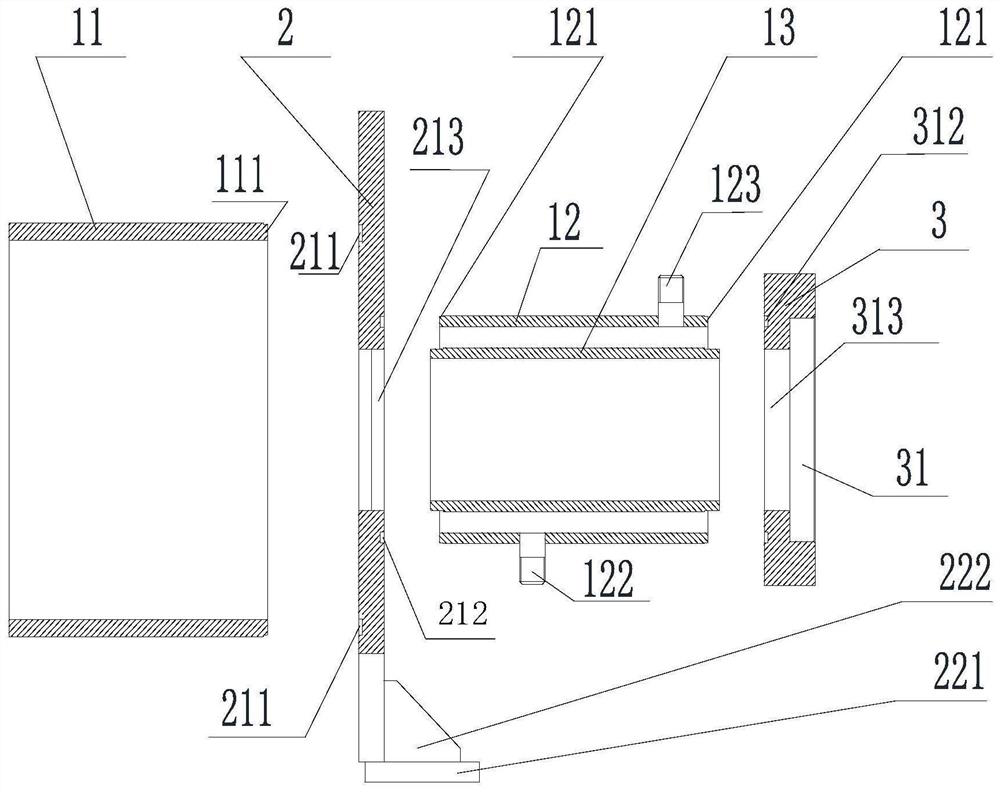

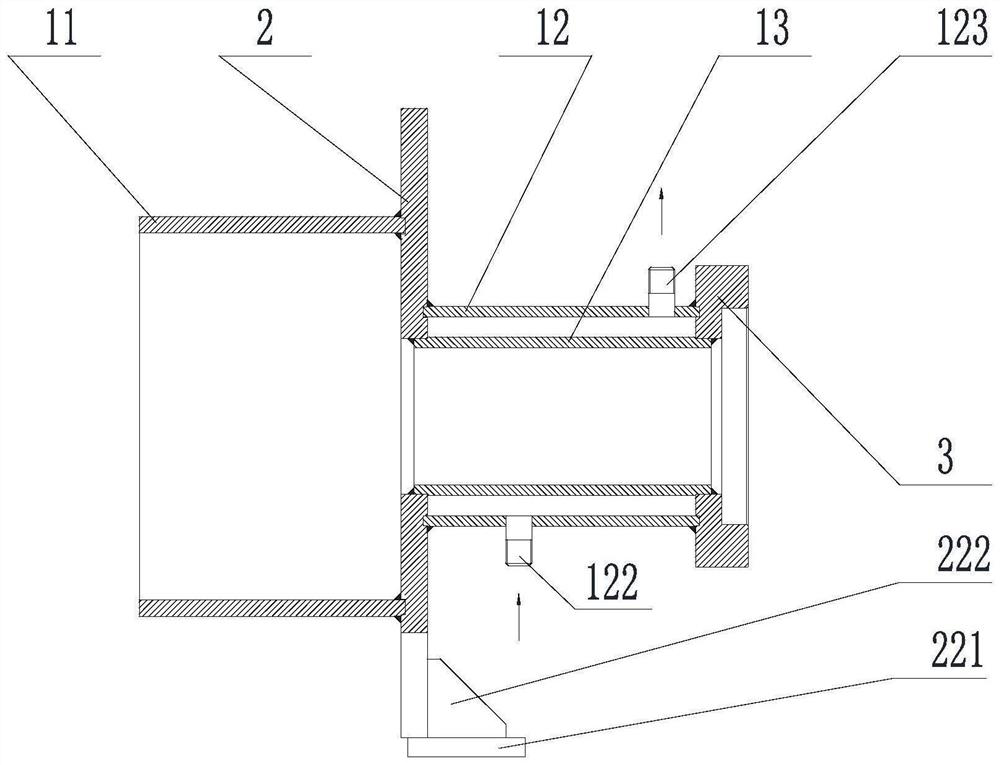

[0037] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a transition roller table bearing installation plate, including a first steel pipe 11 , a middle connecting plate 2 , a second steel pipe 12 , a third steel pipe 13 and an end connecting plate 3 .

[0038] The first steel pipe 11, the second steel pipe 12, and the third steel pipe 13 are all round pipes, and the right side of the first steel pipe 11 is increased with a 3mm long annular first positioning piece 111, and the thickness dimension of the first positioning piece 111 is less than The thickness of the first steel pipe 11, the inner wall of the first positioning member 111 is flush with the inner wall of the first steel pipe 11, the outer wall of the first positioning member 111 and the outer wall of the first steel pipe 11 form a step shape, and the left side of the first steel pipe 11 The side is connected with the sealed box.

[0039] The two ends of the second steel pipe 12 are incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com