Assembly mechanism for increasing torque of hydraulic retarder

A hydraulic retarder and retarder technology, applied in the direction of liquid resistance brakes, mechanical equipment, brake types, etc., can solve unfavorable mass production and assembly, inability to install directly, reduction of effective diameter of retarder output shaft, etc. problems, to achieve the effect of protecting life and property safety, improving assembly efficiency, and ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

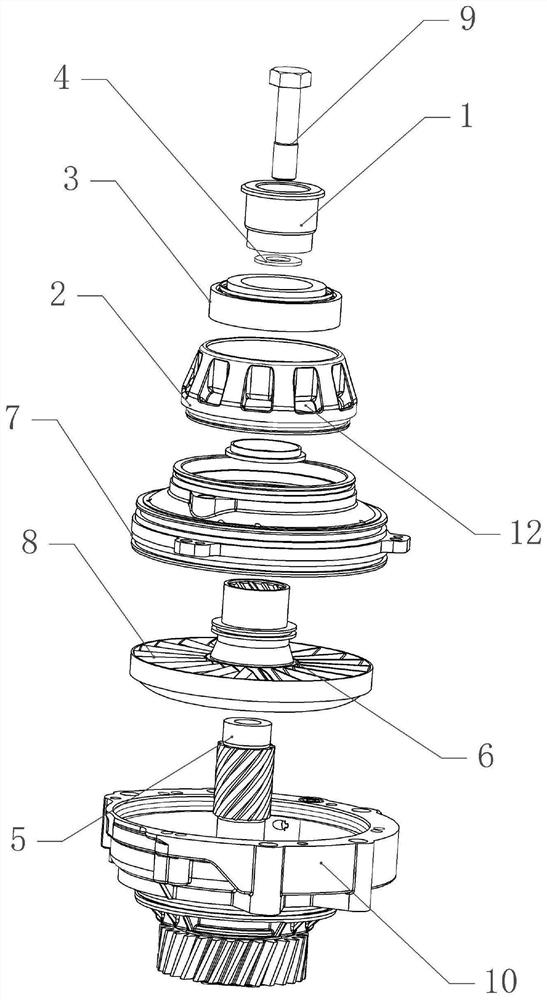

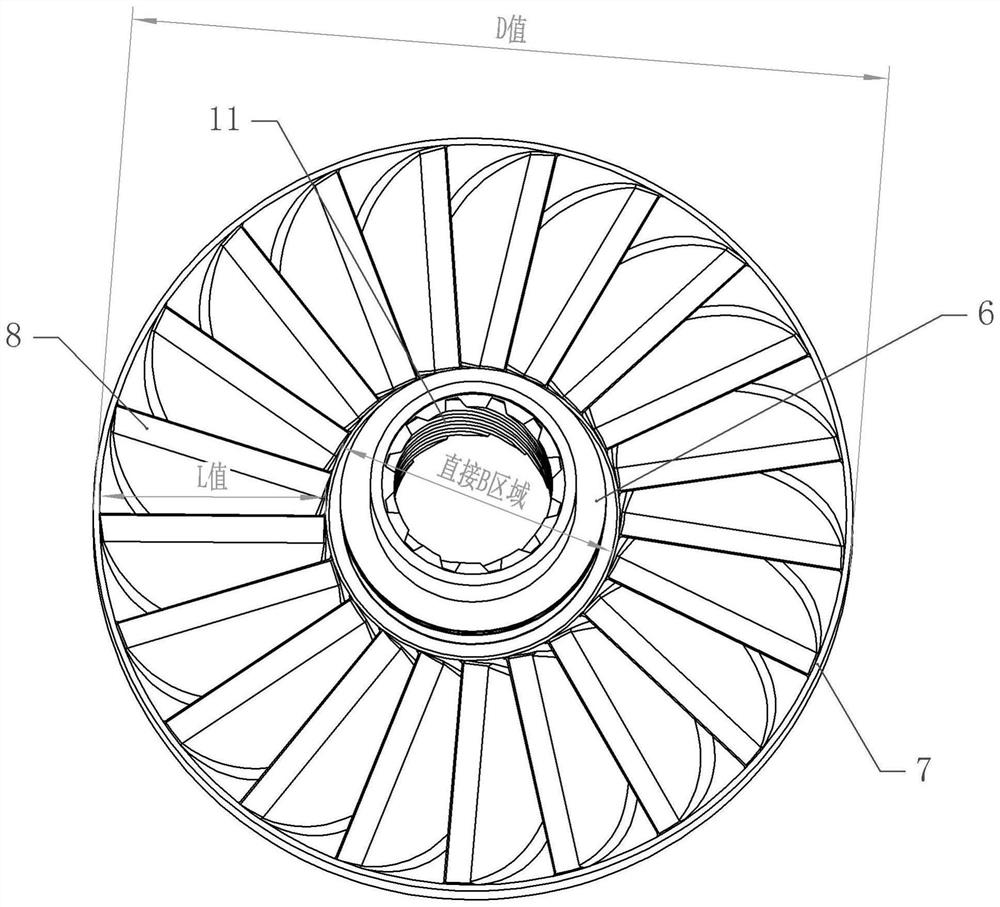

[0028] Basic as attached figure 1 And attached figure 2 As shown, a component mechanism for increasing the torque of a hydraulic retarder includes a retarder housing 10, the upper bolt of the retarder housing 10 is fixed with a bearing race 2, and the circumference of the bearing race 2 is provided with several The oil inlet hole 12 and the bearing race 2 are coaxially fixed with a bearing 3, and the bearing 3 in this embodiment is a tapered roller bearing.

[0029] A shaft diameter ring 1 is coaxially fixed inside the bearing 3, and the shaft diameter ring 1 is coaxially fixed with a retarder output shaft 5, and the end of the retarder output shaft 5 is threaded to a limit piece, and the limit piece is a limit bolt 9 , the limit bolt 9 rotates with the retarder housing 10, that is, the limit bolt 9 limits the retarder output shaft 5. A free gap adjustment block 4 is arranged between the shaft diameter ring 1 and the output shaft 5 of the retarder, and the free gap adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com