Hydraulic suspension decoupling vibration isolation device

A hydraulic suspension and decoupling technology, applied in the direction of shock absorber, shock absorber-spring combination, spring/shock absorber, etc., can solve problems such as affecting the backflow of damping fluid, affecting the car experience, and abnormal sound of cavitation , to achieve a stable shock absorption effect and improve the riding experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

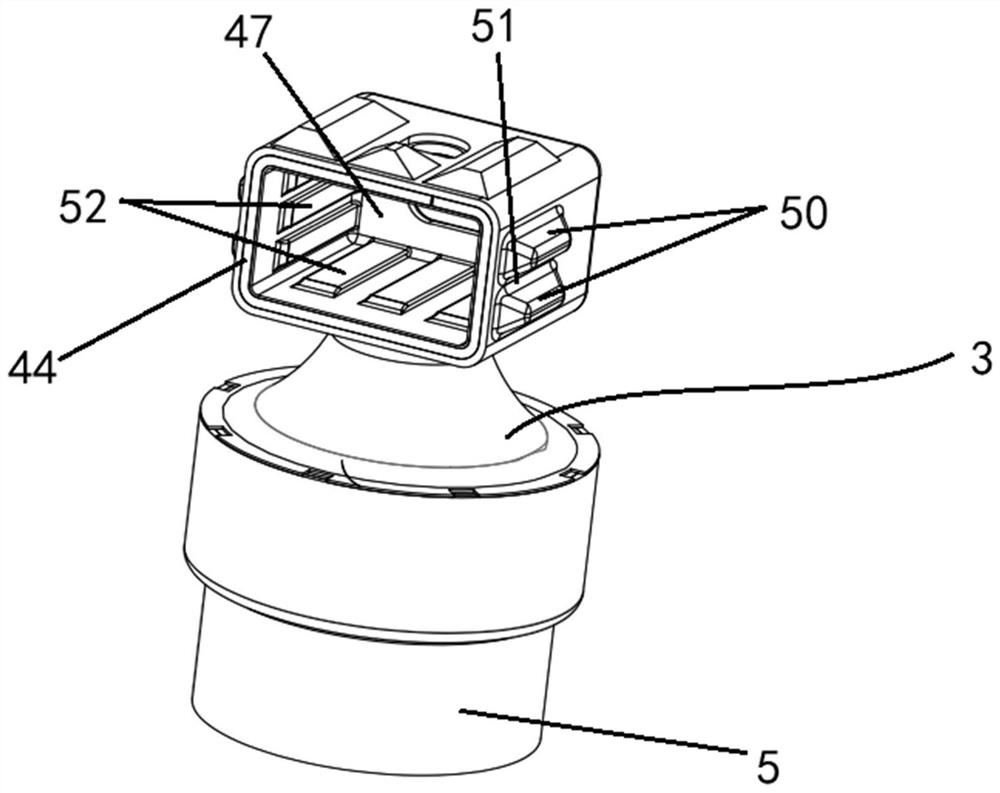

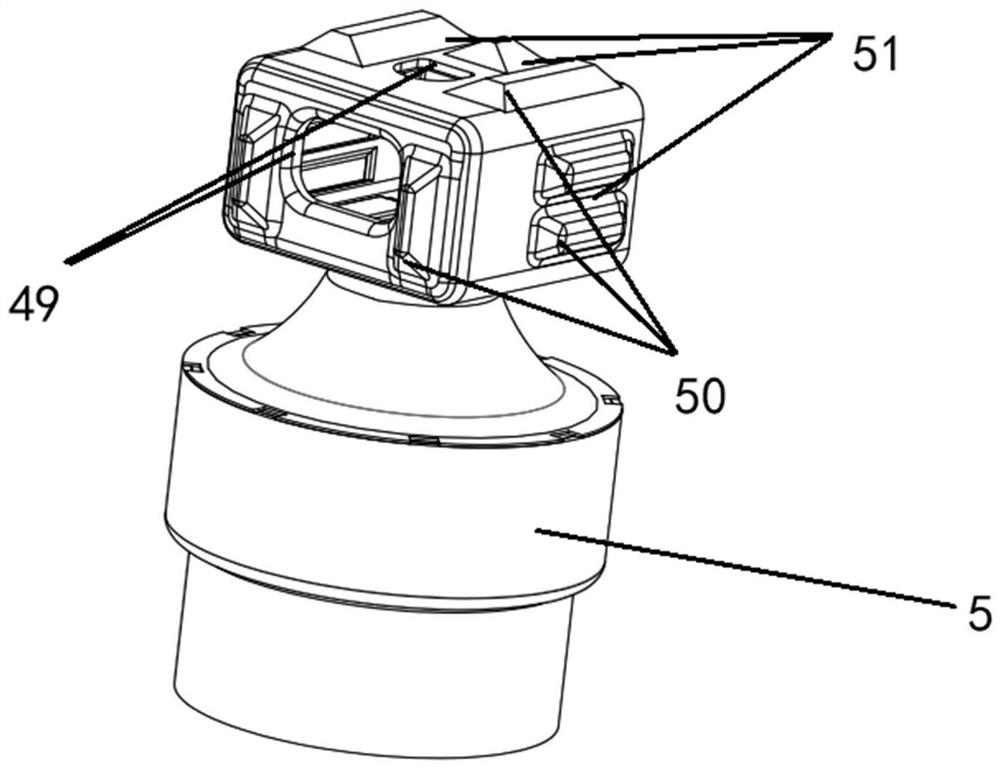

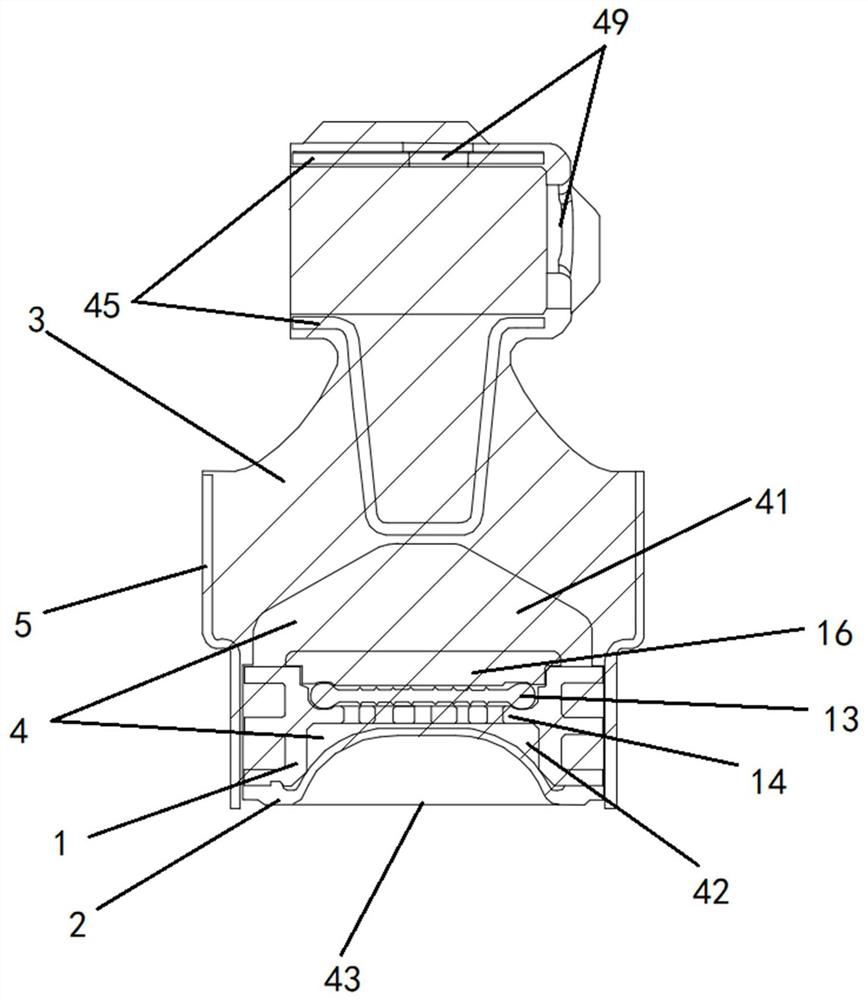

[0044] Such as Figure 1-10As shown, a hydraulic suspension decoupling vibration isolation device includes a valve body 1, and the valve body 1 includes a through hole 11 and a flow channel 12; the through hole 11 is set in the valve body 1, and the flow channel 12 is set in the valve body 1; a flow channel opening 121 is provided in the flow channel 12, and the through hole 11 and the flow channel 12 communicate through the flow channel opening 121; a decoupling plate 13 and a flow limiting plate 14 are provided in the through hole 11, and the Passing holes 15 are distributed on the restrictor plate 14, and the level of the restrictor plate 14 is higher than the level of the flow channel opening 121, and the decoupling plate 13 covers the upper surface of the restrictor plate 14; The plate 14 defines the position of the decoupling disk 13, so that the decoupling disk 13 is in a position that is convenient to open, and then the decoupling disk 13 can be opened when the damping...

Embodiment 2

[0064] Such as Figure 11-12 As shown, in this embodiment, the flow channel includes a flow channel inlet 122 and two flow channel openings 121; the flow channel opening 121 includes a first flow channel outlet 61 and a second flow channel outlet 62, and the flow channel inlet 122 and the second flow channel outlet 62 are arranged at both ends of the flow channel, and the first flow channel outlet 61 is arranged between the flow channel inlet 122 and the second flow channel outlet 62, and the height of the first flow channel outlet 61 is lower than the flow limit The horizontal height of the plate; between the channel inlet 122 and the first channel outlet 61 is the first channel 64, between the first channel outlet 61 and the second channel outlet 62 is the second channel 65, and the first channel outlet 61 Make the through hole communicate with the first flow channel 64 and the second flow channel 65; the flow channel communicates with the upper liquid chamber 41 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com