Compression-resistant and impact-resistant mobile explosion-proof monitoring terminal equipment

A monitoring terminal and shock-resistant technology, applied in mechanical equipment, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of construction site changes, increased labor costs, inability to move at any time, etc., to improve compression and shock resistance. , the effect of reducing monitoring costs and improving protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

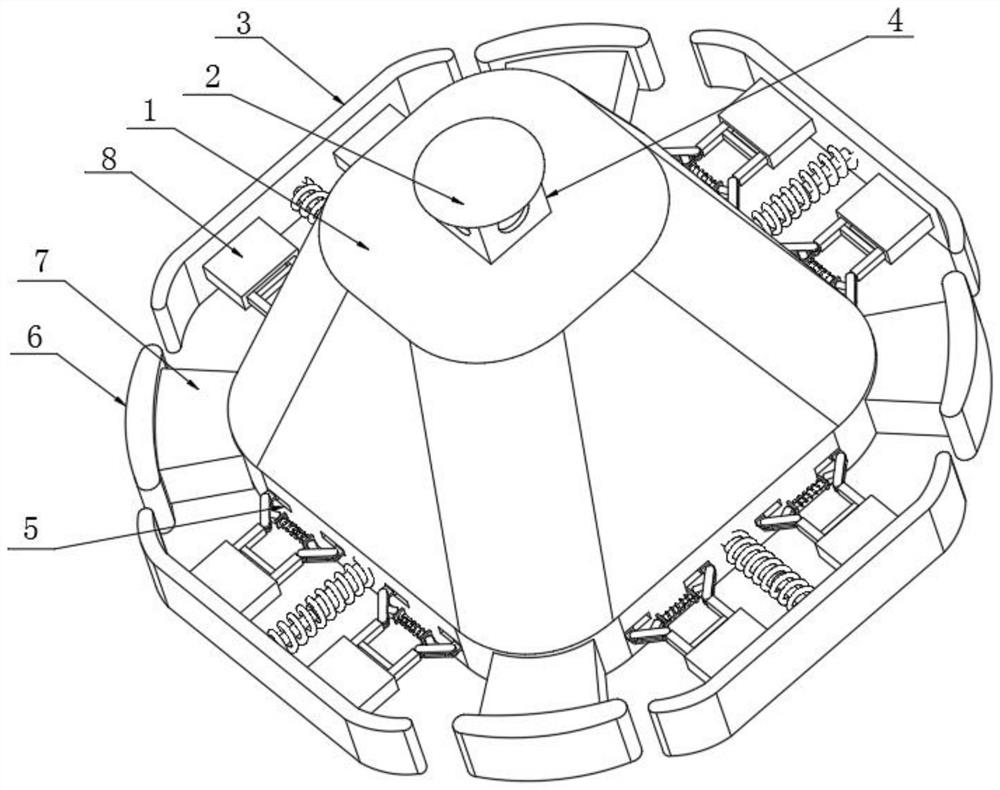

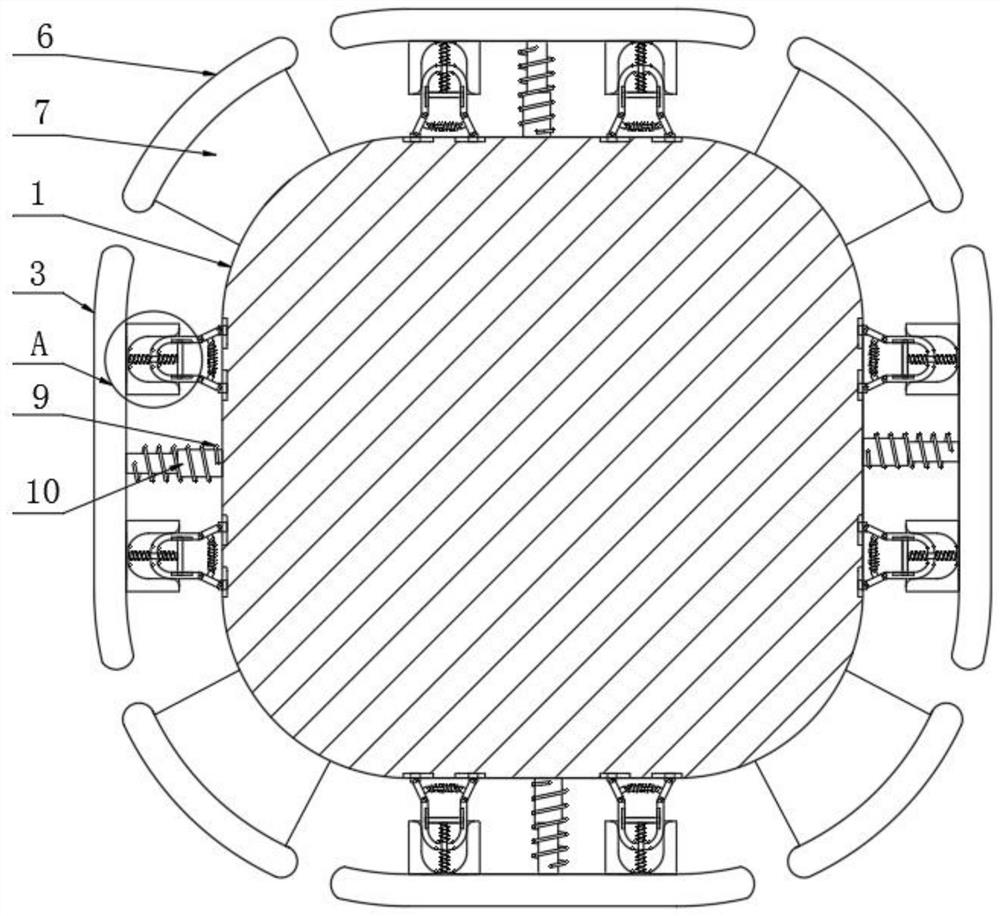

[0031] Embodiment 1, with reference to attached Figure 1-8 , a mobile explosion-proof monitoring terminal device that is resistant to pressure and shock provided by the present invention, including a detection terminal body 1, an anti-shock mechanism is provided on the outside of the detection terminal body 1, and four pressure-resistant Assemblies, the top of the detection terminal body 1 is provided with a square groove 38, and the top of the square groove 38 is provided with an explosion-proof detection mechanism;

[0032] The anti-shock mechanism includes an anti-shock assembly, the anti-shock assembly includes four impact baffles 3, the four impact baffles 3 are equidistantly distributed outside the detection terminal body 1, and one side of the impact baffle 3 is fixed Two buffer shells 8 are connected, one side of the two buffer shells 8 is provided with a U-shaped connecting plate 14, one end of the two U-shaped connecting plates 14 extends into the interior of the bu...

Embodiment 2

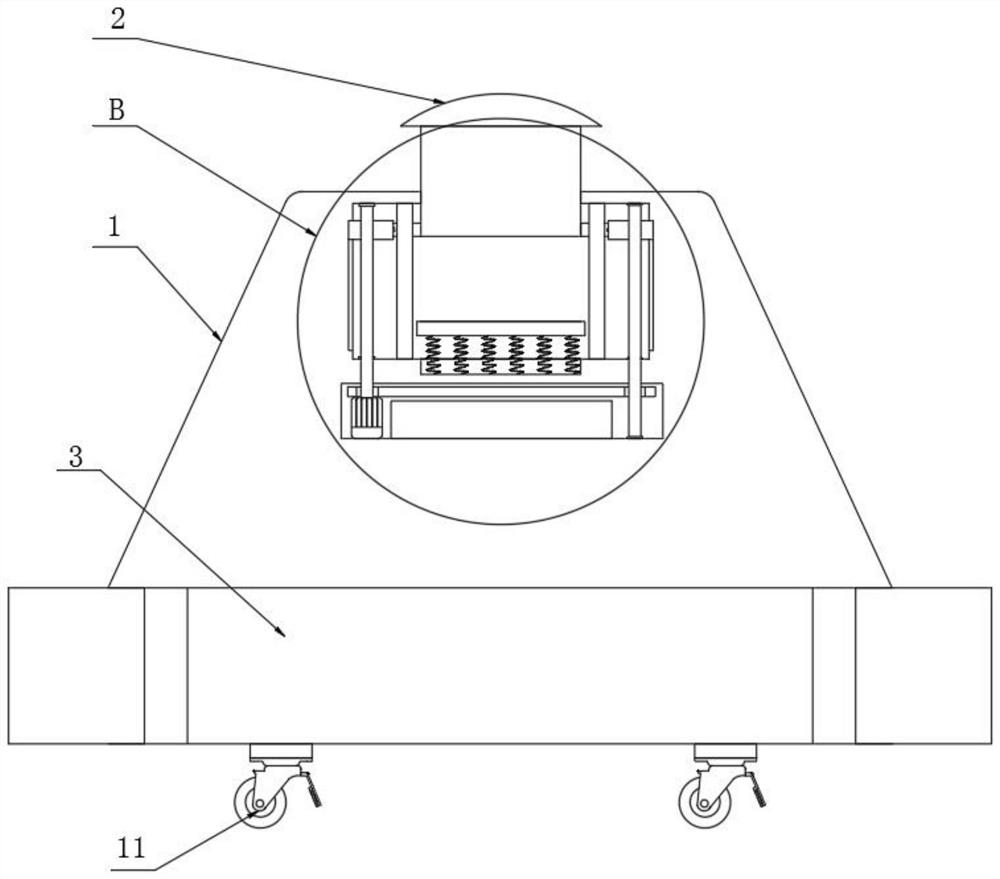

[0042] Embodiment 2, with reference to attached Figure 9 , a mobile explosion-proof monitoring terminal device that is resistant to pressure and shock provided by the present invention, the pressure-resistant component includes a sleeve 39, the sleeve 39 is fixedly connected to the detection terminal body 1, and one side of the sleeve 39 is provided with A support rod 40, the support rod 40 is fixedly connected with the impact baffle 3, one end of the support rod 40 extends into the inside of the sleeve 39, the inside of the sleeve 39 is provided with a seventh spring 41, and the seventh spring 41 is connected to the The support rods 40 are in contact.

[0043] The use process of the present invention is as follows: when using the present invention, start motor 35, and motor 35 starts and drives first screw mandrel 31 to rotate, and first screw mandrel 31 rotates and drives pulley 37 to rotate, and pulley 37 rotates and drives belt 34 to rotate, The second screw mandrel 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com