Multi-optical-axis image deviation calibration method based on servo rotation

A calibration method and multi-optical axis technology, applied in the direction of testing optical performance, etc., can solve problems such as out-of-tolerance core indicators of photoelectric systems, deviation from the range of indicators, etc., to improve field maintainability, save time and labor costs, and improve maintainability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

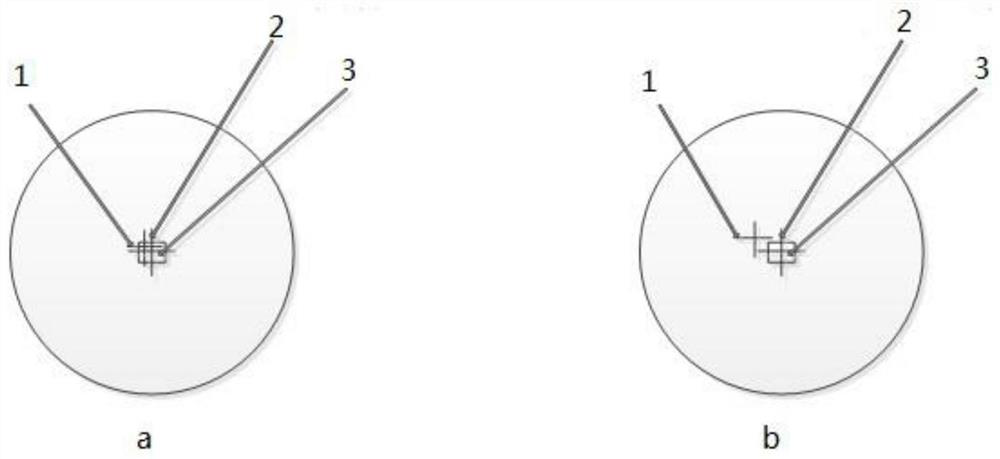

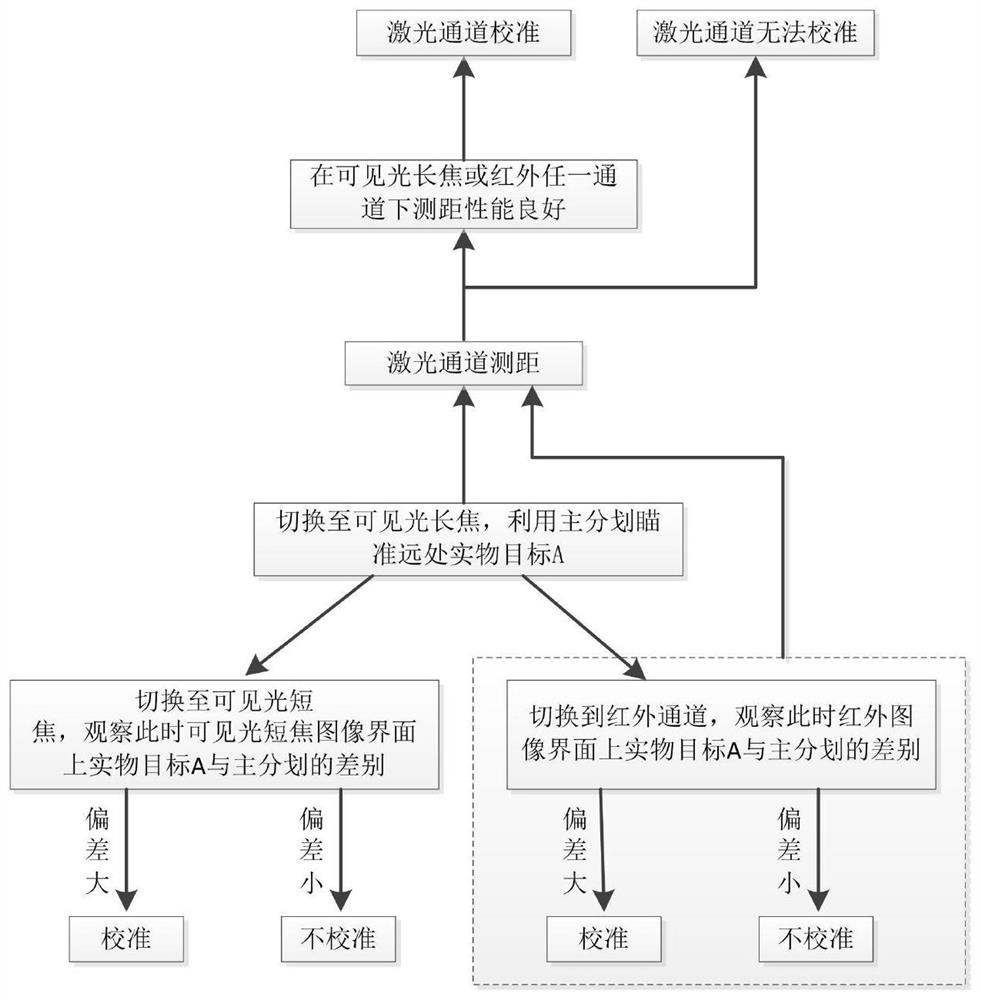

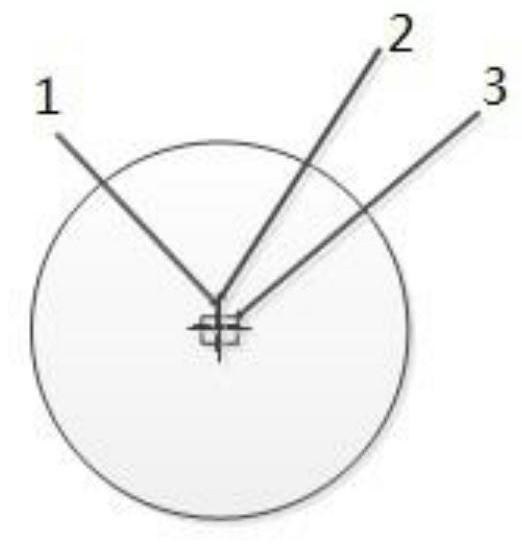

[0028] Such as figure 2 As shown, this embodiment provides a multi-optical-axis image deviation calibration method based on servo rotation. The calibration method uses the high-precision output of the turntable position to compensate, and realizes that the optical system does not need to be disassembled and re-adjusted. Calibration can be realized, and the calibration method first performs parallelism evaluation, and then performs specific calibration;

[0029] The complex photoelectric system has its own servo platform, which can be two-axis or three-axis, and finally can realize the free-space pointing change of the optical aiming axis system. Through the mutual relationship between the optical axes, the relative positional relationship between the two or three is determined, and this relationship is stable.

[0030] For the multi-optical system, due to the different working mechanisms of its multiple independent optical channels, each channel has its own working mode, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com