Active heat dissipation cooling method for packaged semiconductor

A technology of active heat dissipation and cooling method, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as heat residue, and achieve the effect of improving speed, improving heat dissipation efficiency, and reducing power resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

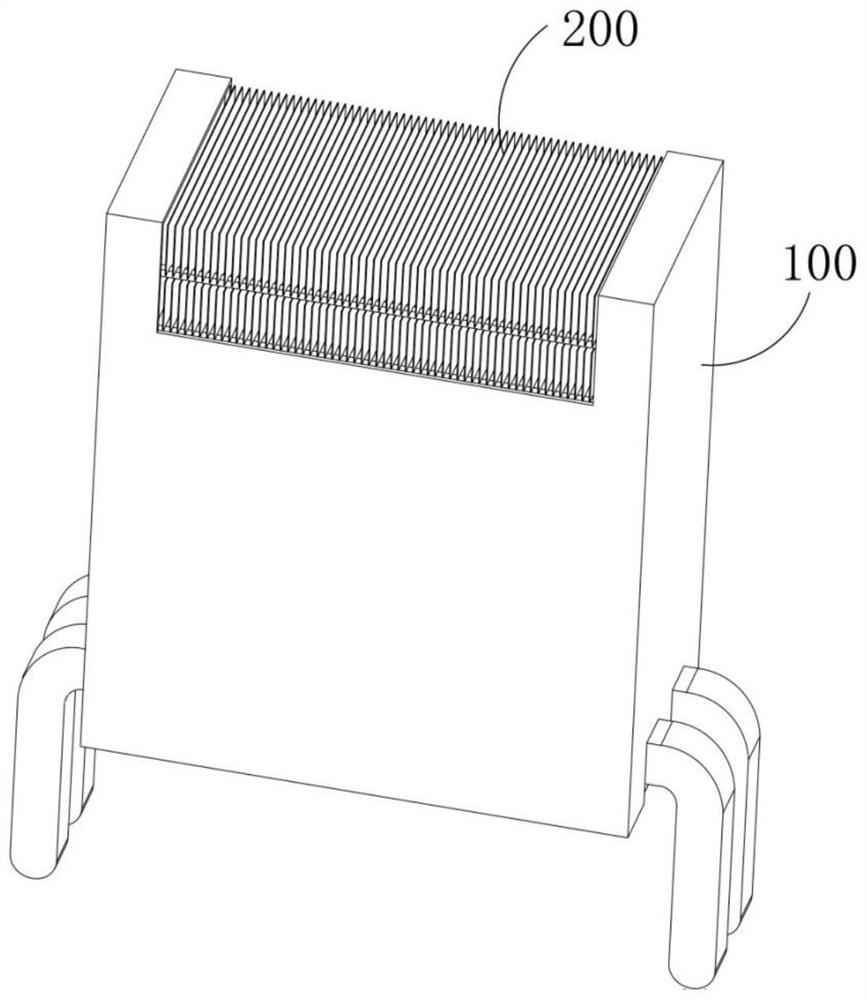

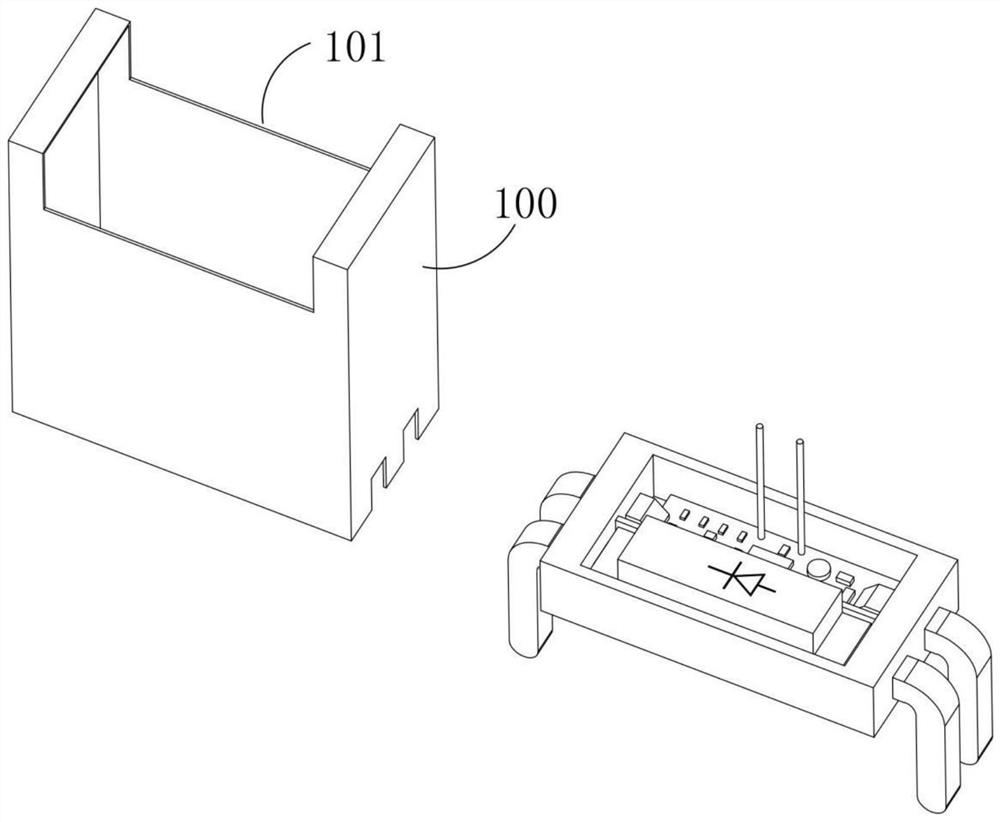

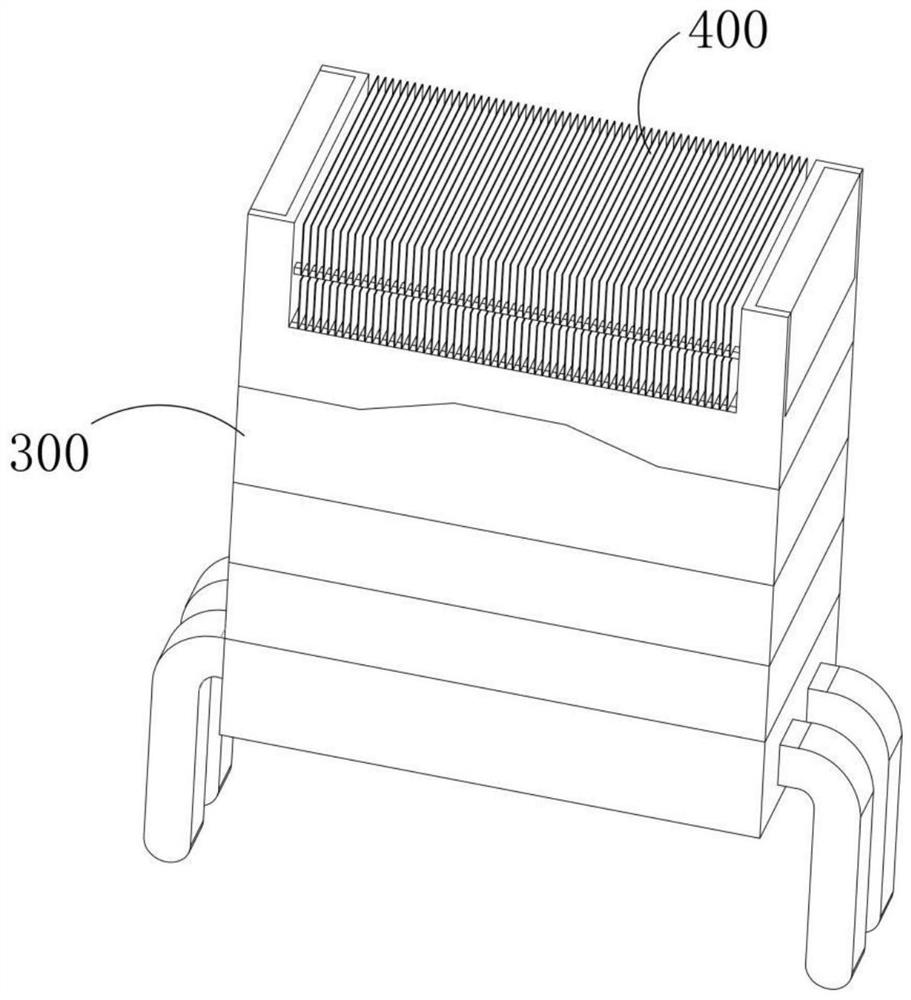

[0058] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0059] An active heat dissipation and cooling method for packaging semiconductors, the steps of which are:

[0060] S1: The heat generated during semiconductor operation is transferred to the sponge body 322 in the heat transfer member b320 through the liquid medium in the liquid storage tank 317 in the heat transfer member a310, and then the liquid medium in the sponge body 322 is evaporated, and the sponge body 322 After the liquid medium inside evaporates, the sponge body 322 absorbs the liquid medium in the liquid storage tank 317, and then continuously produces the liquid medium in a vaporized state;

[0061] S2: The vaporized liquid medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com