Stator punching sheet, stator core, motor stator and motor

A technology for stator punching and stator core, which is applied in the fields of stator punching, stator core, motor stator and motor, which can solve the problem that ordinary AC single-phase asynchronous motors cannot meet the requirements of ordinary AC single-phase asynchronous motors, the control cost of DC motor products is increased, and customer needs cannot be met. and other problems, to achieve the effect of convenient coil winding, simple structure and improved product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

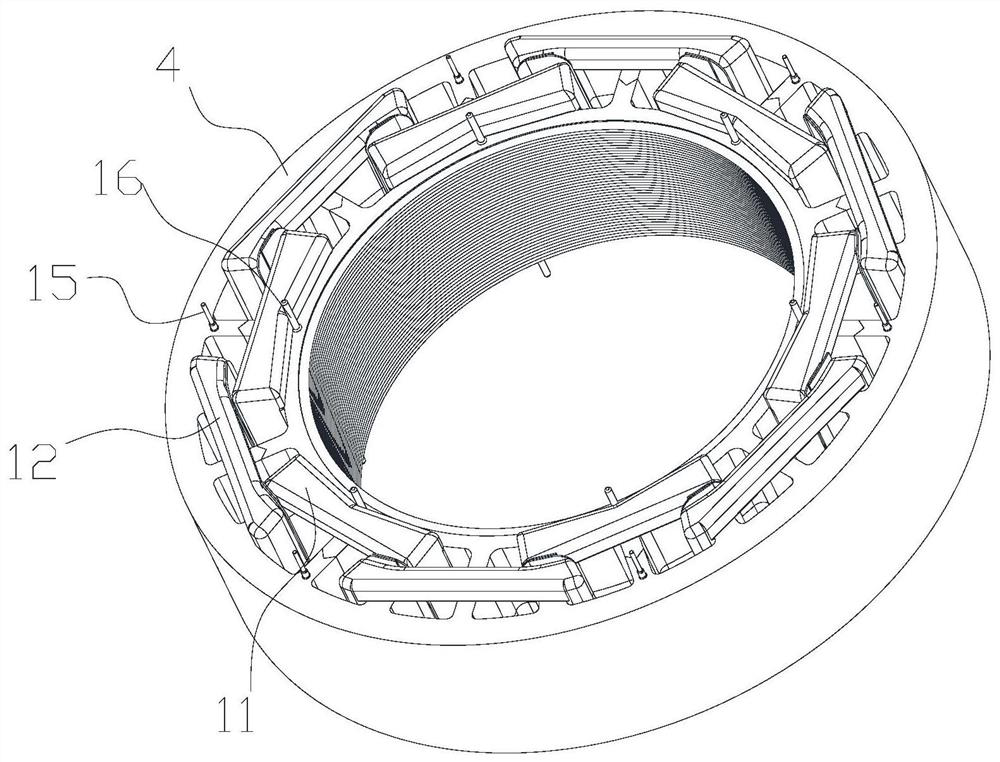

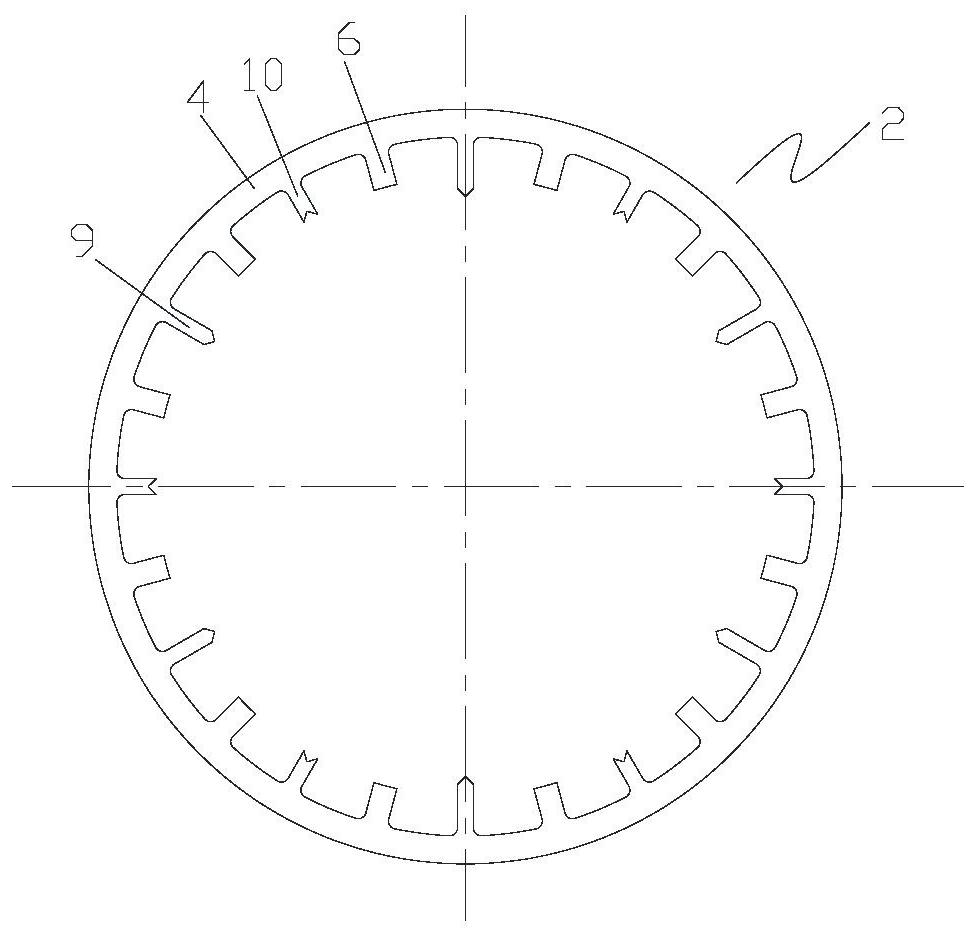

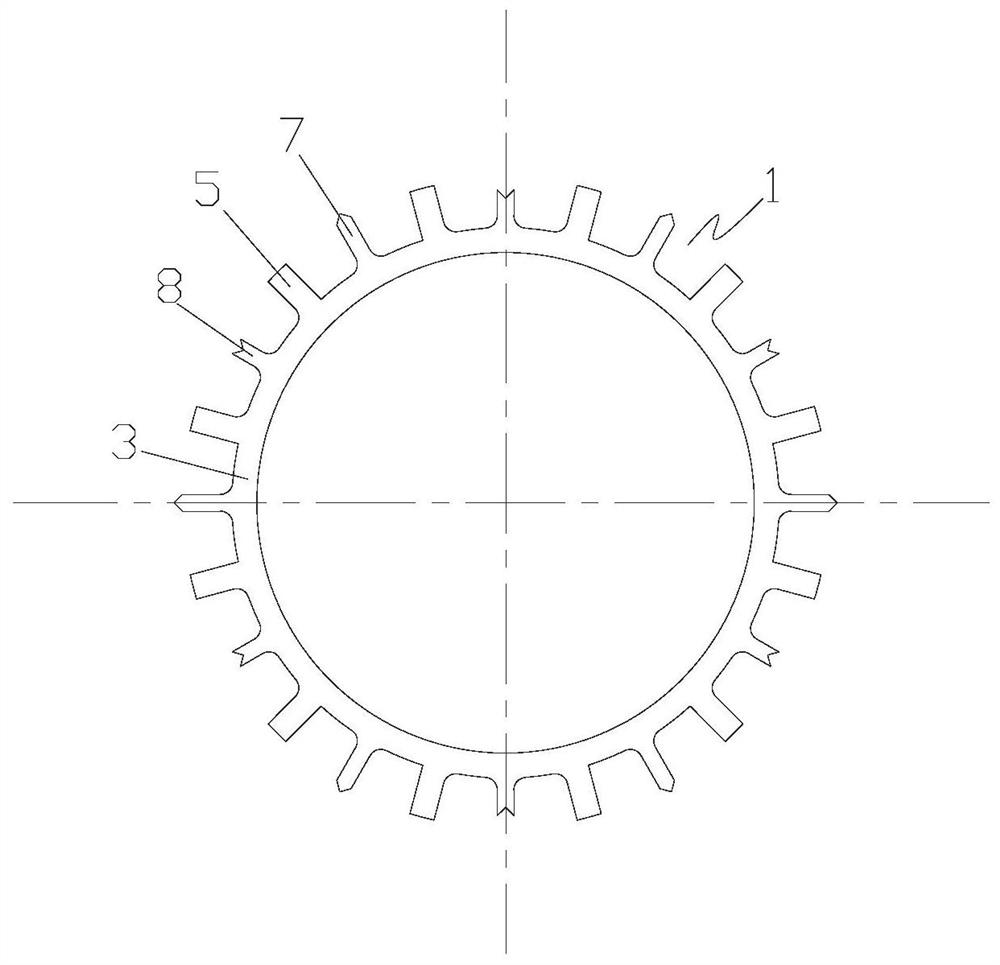

[0039] see in conjunction Figure 1 to Figure 15 As shown, according to the embodiment of the present application, the stator punching sheet includes an inner layer punching sheet 1 and an outer layer punching sheet 2 designed separately, and the inner layer punching sheet 1 includes a stator inner ring 3 and an inner ring 3 arranged on the outer peripheral side of the stator inner ring 3 The winding inner teeth, the outer punching sheet 2 includes the stator outer ring 4 and the winding outer teeth arranged on the inner peripheral side of the stator outer ring 4, the winding inner teeth can be connected with the winding outer teeth to form a closed slot.

[0040] The stator punching sheet adopts the separately designed inner layer punching sheet 1 and outer layer punching sheet 2, which can be used to form the separately designed inner layer iron core and outer layer iron core, And the closed slot structure is formed by combining the inner layer iron core and the outer layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com