Temperature control method and system for platinum channel of float process

A temperature control method and platinum channel technology, applied in manufacturing tools, glass manufacturing equipment, feeding troughs, etc., can solve problems such as small production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

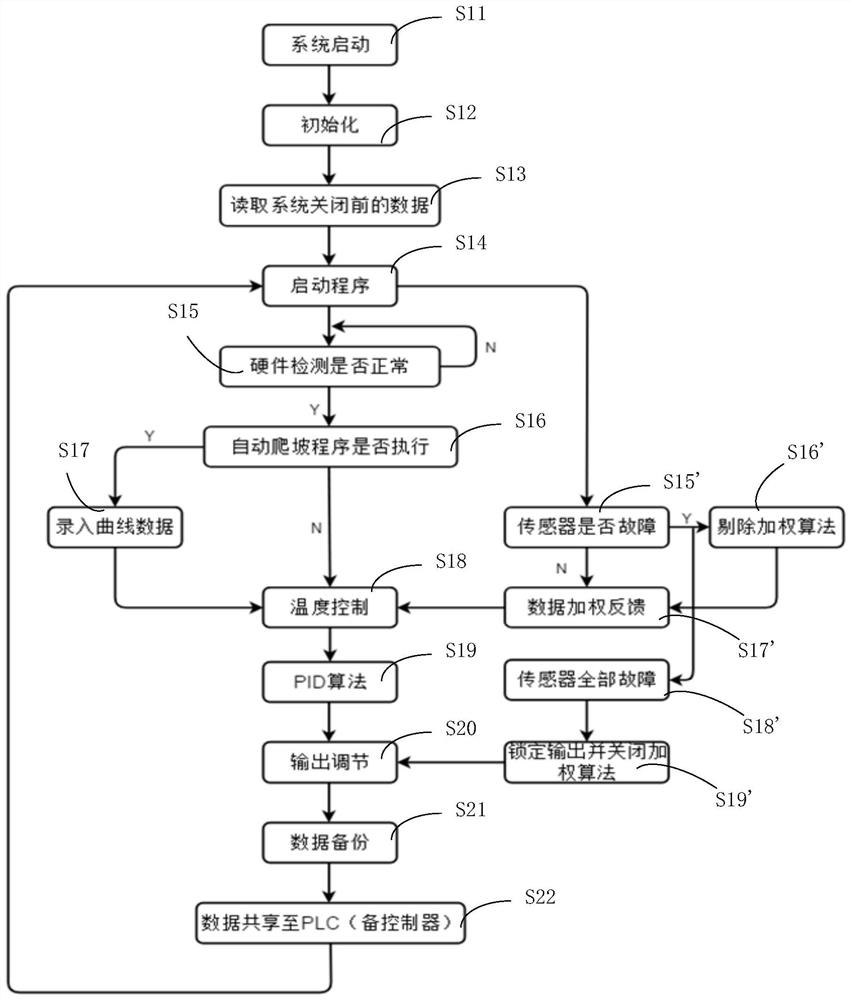

[0054] The invention provides a method for temperature control of a platinum channel in a float process, the method comprising:

[0055] S1: To meet the special process requirements of the platinum channel, establish a ring redundant network, including:

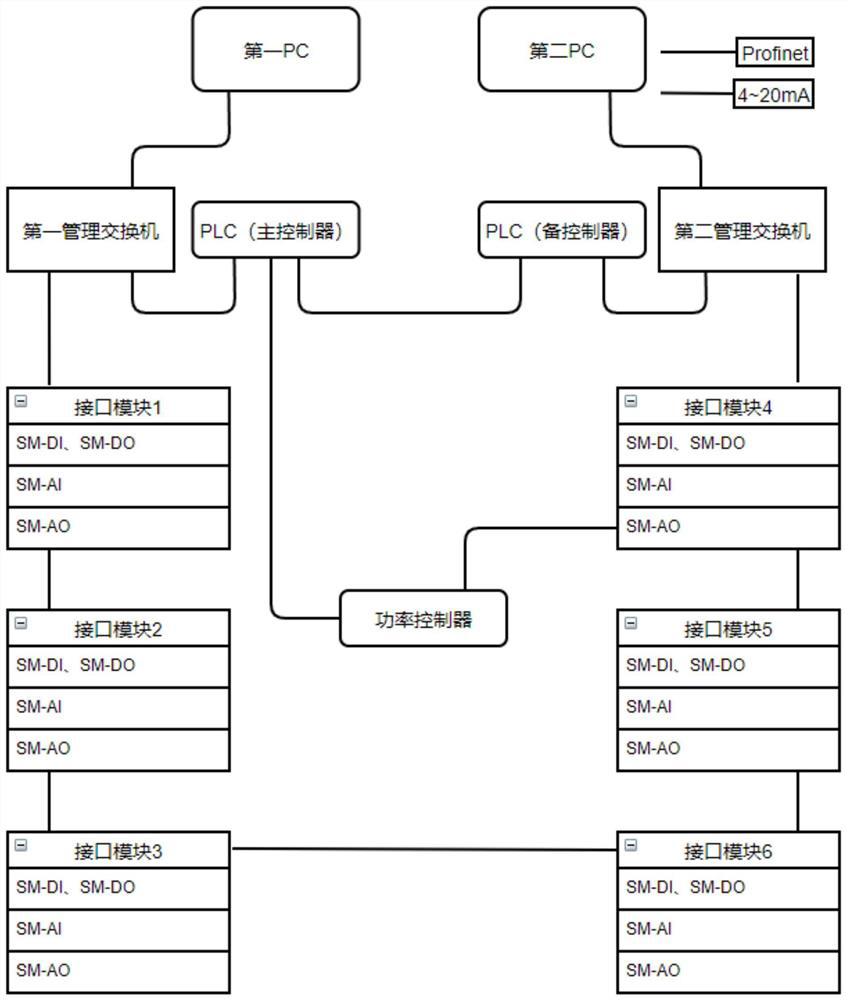

[0056] figure 1 It is a ring redundant network diagram of the system, such as figure 1 As shown, PLC (master controller), first management switch, interface module 1, interface module 2, interface module 3, interface module 4, interface module 5, interface module 6, second management switch, PLC (standby controller ) are connected from end to end through standard industrial Ethernet, and then PLC (main controller) and PLC (standby controller) are connected to form a ring redundant network. The first PC is connected to the first management switch, and the second PC is connected to the second management switch. The power controllers are connected to the PLC (main controller) and the interface module 4, respectively.

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com