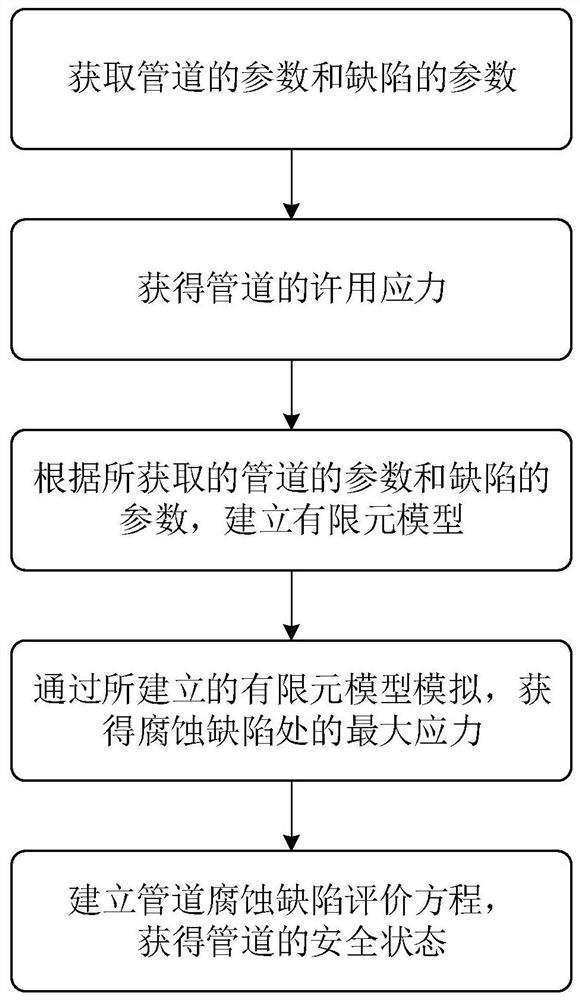

Method for evaluating corrosion defect of pipeline

A defect evaluation and pipeline technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the evaluation formula cannot accurately analyze pipeline corrosion defects, and achieve perfect material models and calculation models, wide application range, The effect of accurate simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the pipeline corrosion defect evaluation method of the present invention is used to analyze the actual oil and gas pipeline of a certain project. Various parameters of the pipeline (pipe material, outer diameter, wall thickness, maximum allowable working pressure MAOP, elastic modulus E, Poisson's ratio, yield stress σ s , tensile strength and safety factor F s ) as shown in the table below.

[0037]

[0038] Allowable stress [σ] = σ s / F s =320 / 2=160MPa.

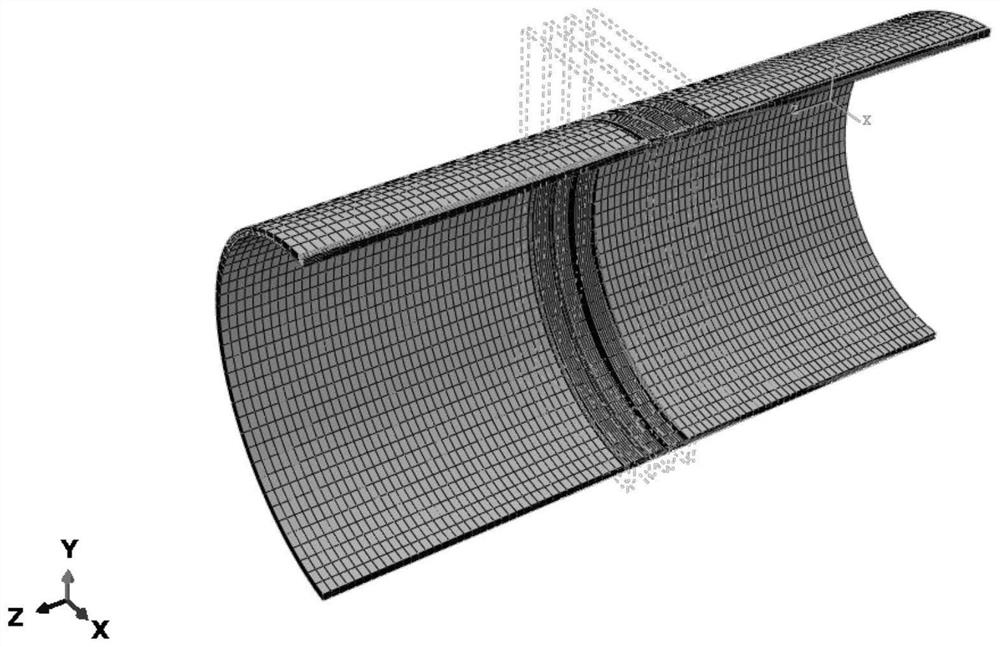

[0039] In this embodiment, the length of the pipeline corrosion defect is 30 mm, the depth is 30% of the wall thickness, and the width is 5.7 mm. Many literatures show that the pressure of the axial defect has a great influence, but the circumferential width has little effect. In this embodiment, the axial defect is used for simulation.

[0040] According to the characteristics of oil and gas pipelines, the finite element model of the pipeline is established as follows: the material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com