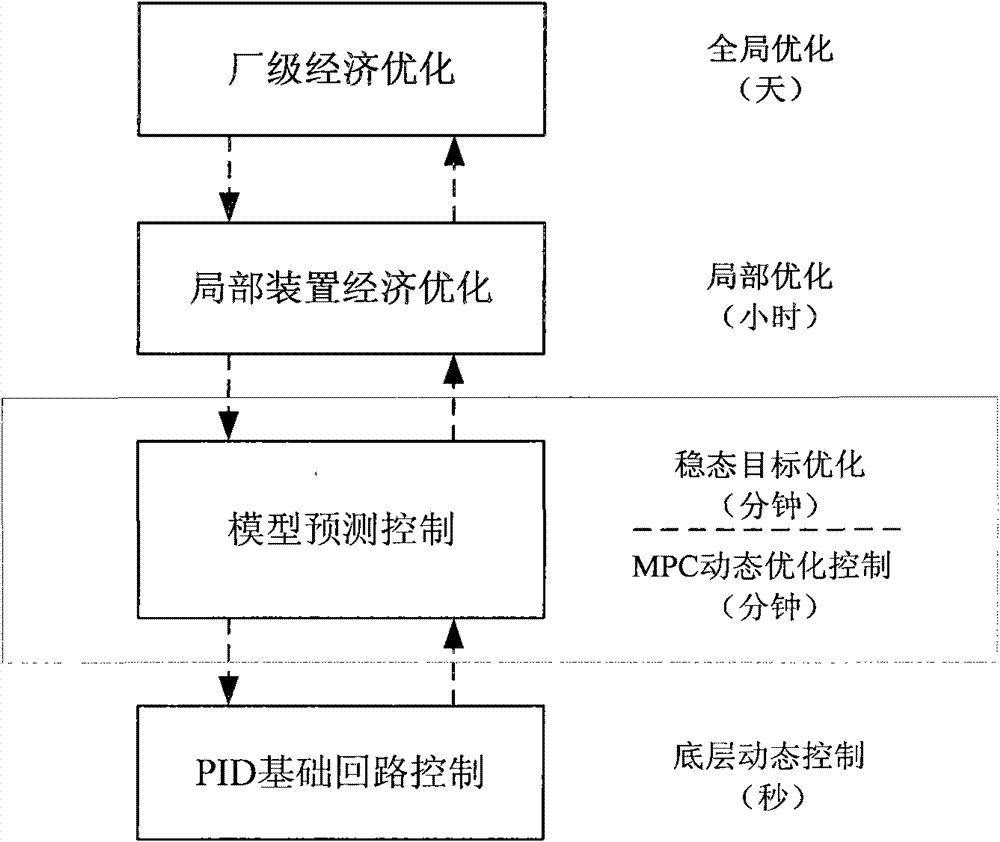

Selection method for economic goal-optimized self-adaptive backoff of chemical process predictive control system

A target optimization and self-adaptive technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as lack of evaluation methods and loss of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

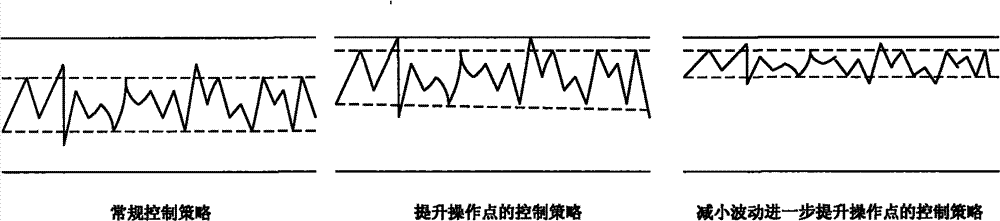

Problems solved by technology

Method used

Image

Examples

Embodiment

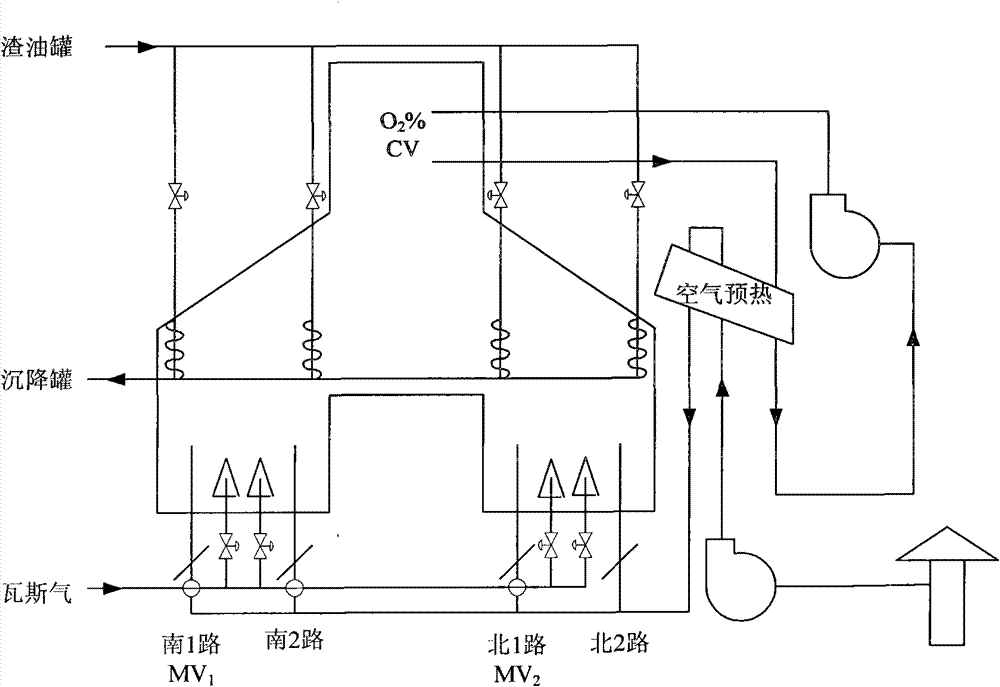

[0117] 1) Select the control variable MV and output variable CV of the chemical process equipment according to the production index, collect the representative process data in the stable operation stage, and calculate the mean value and variance of the current working condition point:

[0118] The heating furnace has 4 air inlet channels, with the south 1 and north 1 air inlet baffles as the operating variables MV1 and MV2, the other two air inlets are kept constant, and the oxygen content at the furnace outlet is used as the controlled variable CV. Collect representative historical data and calculate the mean and variance of the current operating point.

[0119] 2) Determine the economic goals and performance indicators of each production unit:

[0120] The heating furnace provides heat through the combustion of gas. In industrial processes, the thermal efficiency η is usually used to measure the degree of heat energy utilization of the heating furnace participating in heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com