Rigid-flexible printed circuit board capable of improving discoloration of brownification layer of multilayer flexible core board and manufacturing method of rigid-flexible printed circuit board

A technology of rigid-flex board and browning layer, which is applied in the field of PCB manufacturing, can solve the problems of color difference and uneven heating, and achieve the effect of avoiding uneven heating, solving poor color difference and improving poor color difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

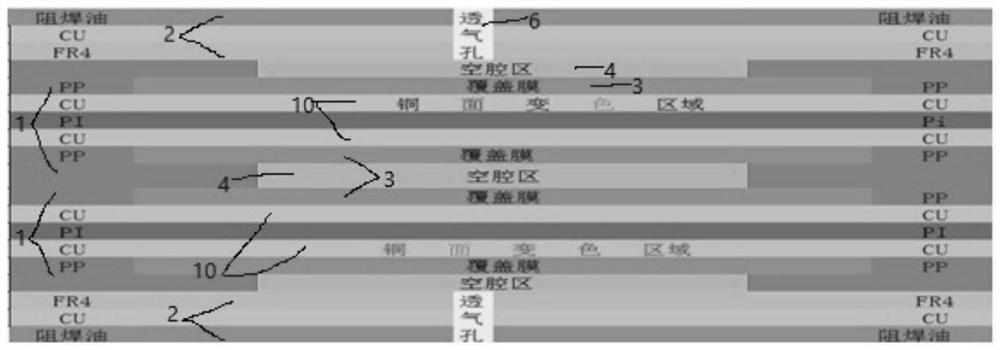

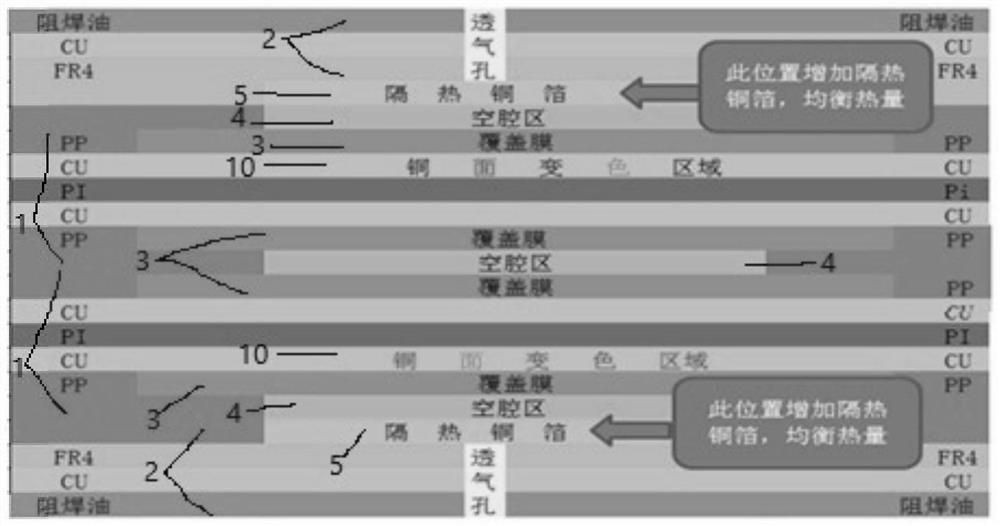

[0020] Example: such as figure 2 As shown, this embodiment provides a rigid-flex board that improves the discoloration of the browning layer of a multi-layer flexible core board, including two inner core boards and a single-sided copper-clad board disposed on one side of the inner core board The two inner core boards are bonded together to form adjacent inner core boards, and the copper surfaces of the two adjacent inner layer core boards are respectively provided with a cover film that is bonded to the copper surface , there is a cavity area between the cover films, and the two ends of the cover film and the cavity area are respectively bonded with PP; the copper surface of the inner core board near the side of the single-sided copper-clad film, the side of the cover film far away from the inner core board is also provided with a cavity area, and the outside of the cavity area of the cover film on the copper surface of the inner core board close to the side of the single-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com