A welding-free square lithium battery module

A lithium battery, welding-free technology, applied to battery components, secondary batteries, circuits, etc., can solve the problems of difficult free assembly and cascade utilization, insufficient capacity, high temperature, etc., to achieve long battery life, balanced temperature difference, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

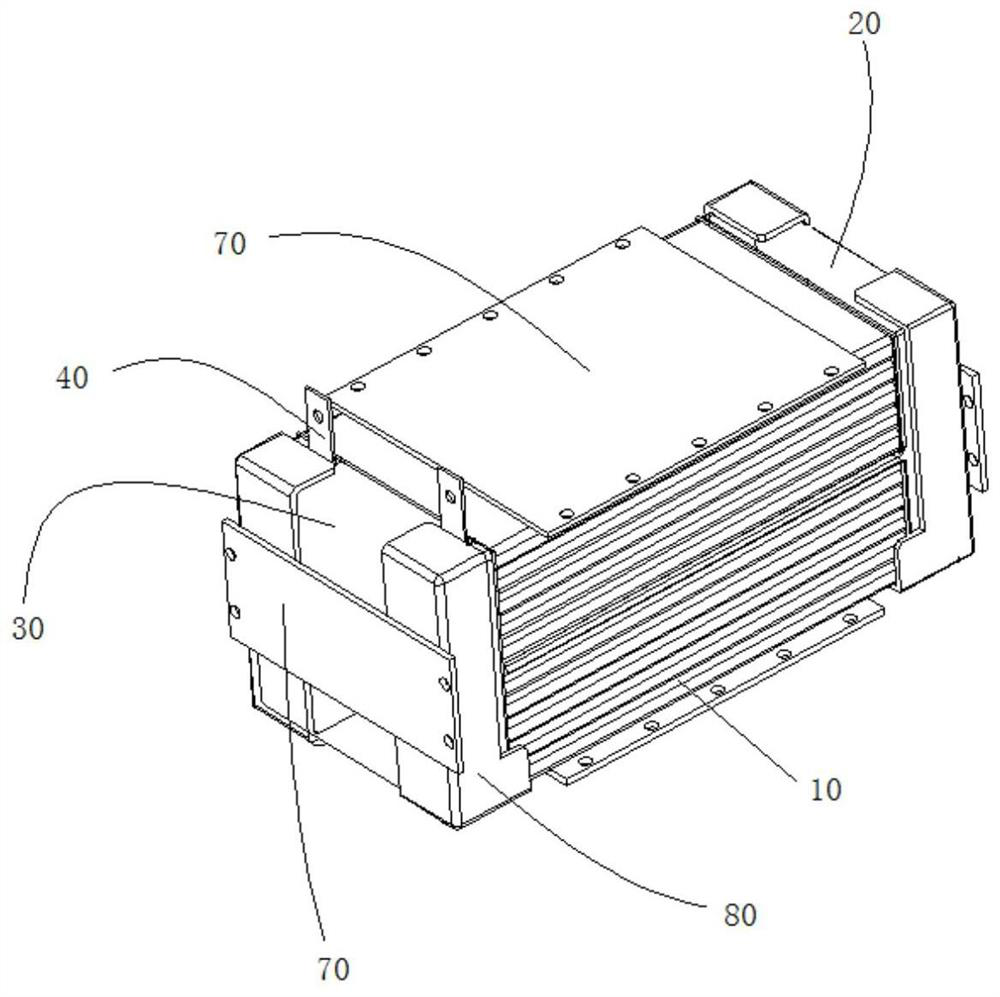

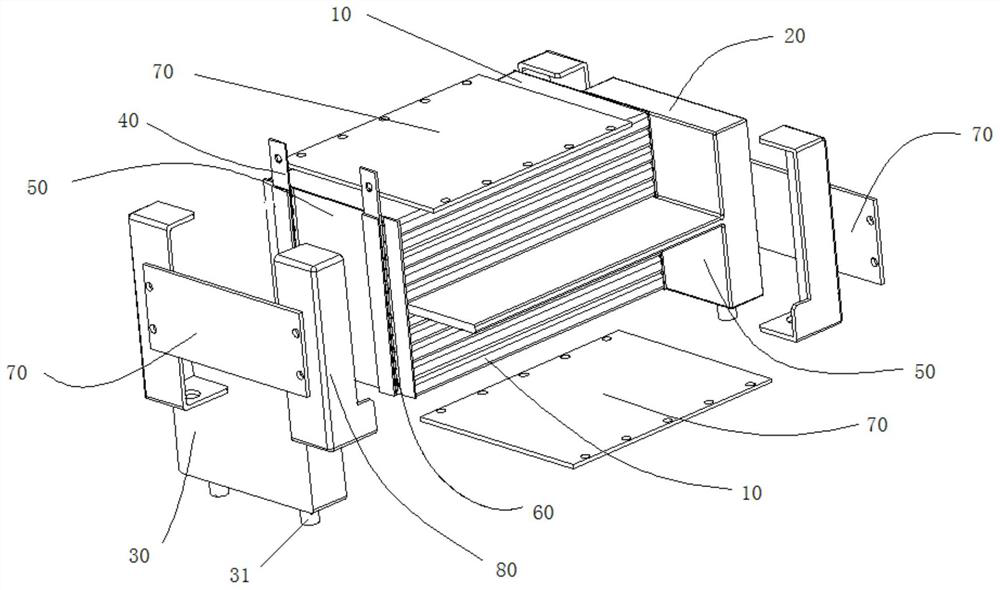

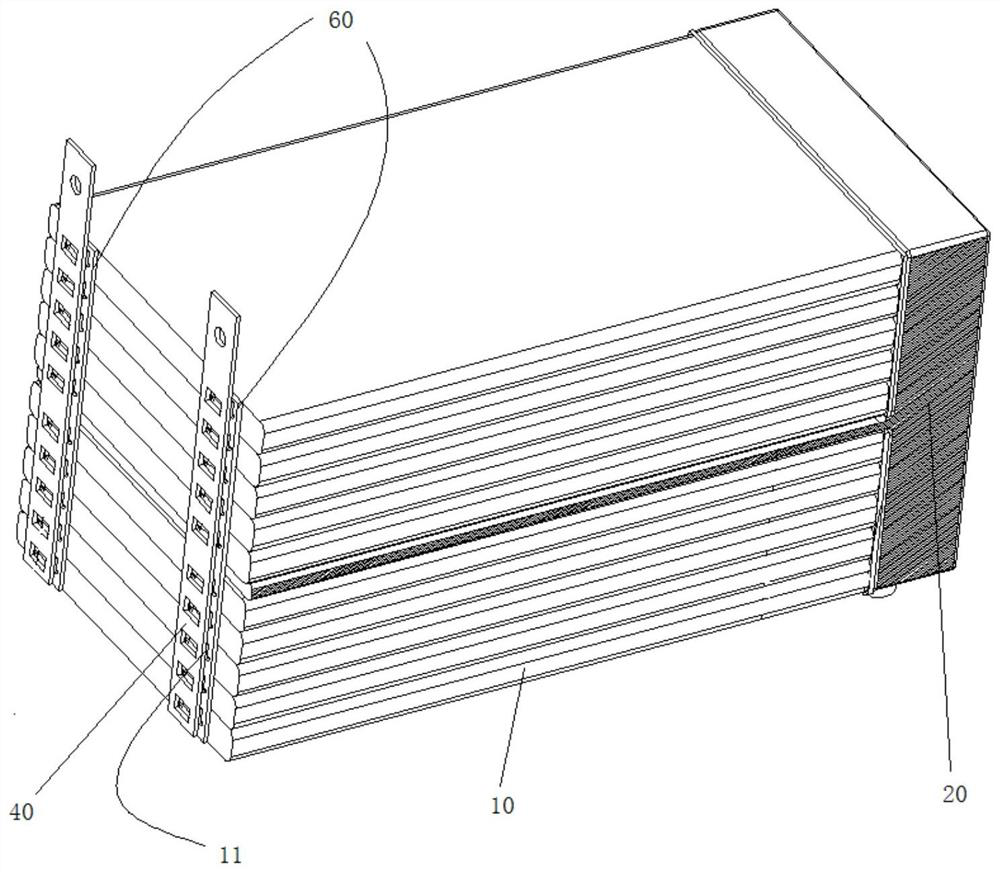

[0030] like figure 1 As shown, a welding-free square lithium battery pack module is suitable for use on battery equipment with mechanical connection and independent thermal management structure, which includes: square lithium battery 10, finned cold plate 20, and the surface is passed through The oxidized cold plate 30 , the electrode contact piece 40 , the pressing plate 50 and the fixing frame 80 .

[0031] The square lithium battery uses a finned cold plate 20 and a cold plate 30 , supplemented by upper, lower, left and right pressure plates 70 and a fixing frame 80 to ensure the stability of the entire square lithium battery module.

[0032] Inside the square lithium battery module, there are square lithium battery 10, finned cold plate 20, cold plate 30, electrode contact piece 40, bonding layer 50 between cold pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com