Uniform preparation device for physical foaming material

A technology of physical foaming and preparation equipment, which is applied in the field of foaming materials, and can solve problems such as inability to cushion shocks, no vibration screening mechanism, and increased fluidity inside the reactor body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

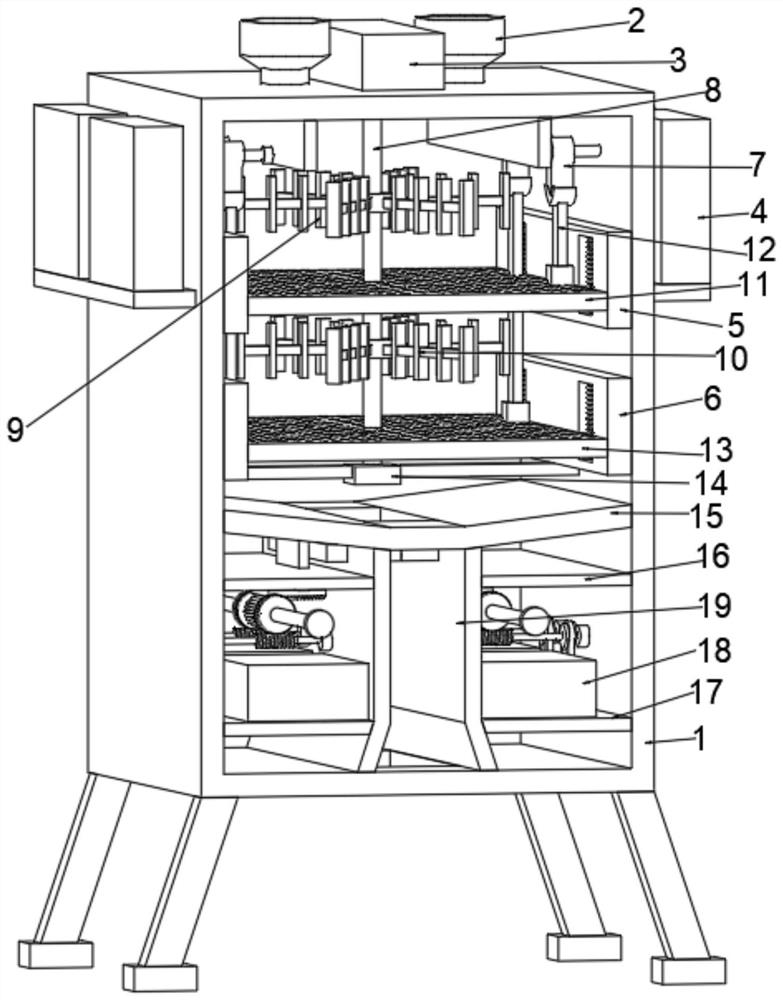

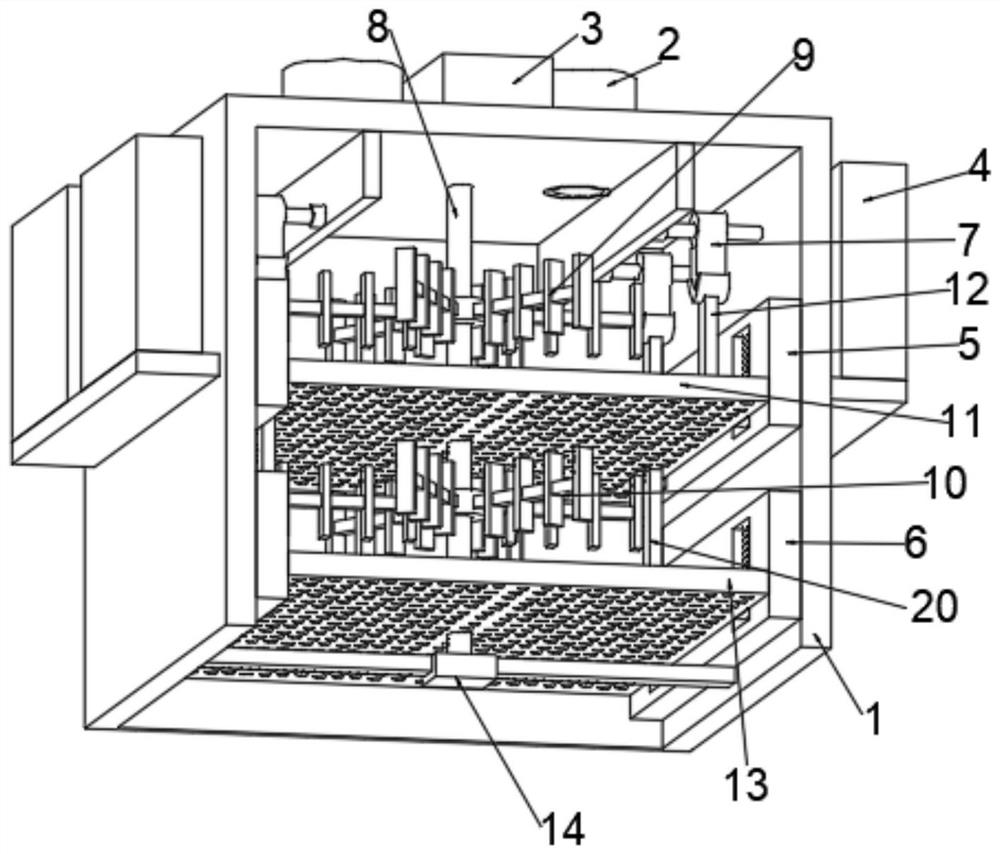

[0028] see Figure 1-Figure 5 , the present invention provides a technical solution: a uniform preparation device for physical foaming materials, including a box body 1, the top inner wall of the box body 1 is fixedly equipped with a feed channel 2, and the bottom end inner wall of the box body 1 is penetrated with the following The material passage, the outside of the discharge passage is provided with a control valve, the top of the box body 1 is fixedly installed with the first motor box 3, the inside of the box body 1 is provided with a cavity, and the inner wall of the cavity is fixedly installed with the first fixed box 5 , the second fixed box 6, connecting plate 14, the first material retaining plate 15, the first partition 16 and the second partition 17, the first fixed case 5 is located above the second fixed case 6, the first material retaining plate 15 1. The first dividing plate 16 and the second dividing plate 17 are fixedly installed on the inner wall of the cav...

Embodiment 2

[0034] see figure 1 , figure 2 , Image 6 , Figure 7 , the present invention provides a technical solution: a uniform preparation device for physical foaming materials, including a box body 1, the top inner wall of the box body 1 is fixedly equipped with a feed channel 2, and the bottom end inner wall of the box body 1 is penetrated with the following The material passage, the outside of the discharge passage is provided with a control valve, the top of the box body 1 is fixedly installed with the first motor box 3, the inside of the box body 1 is provided with a cavity, and the inner wall of the cavity is fixedly installed with the first fixed box 5 , the second fixed box 6, connecting plate 14, the first material retaining plate 15, the first partition 16 and the second partition 17, the first fixed case 5 is located above the second fixed case 6, the first material retaining plate 15 1. The first dividing plate 16 and the second dividing plate 17 are fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com