Synthetic sulfonate additive and preparation method thereof

An additive and sulfonate technology, applied in the field of lubricating oil, can solve the problems of long production cycle, poor water separation performance, easy emulsification of products, etc., and achieve the effect of improving the reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

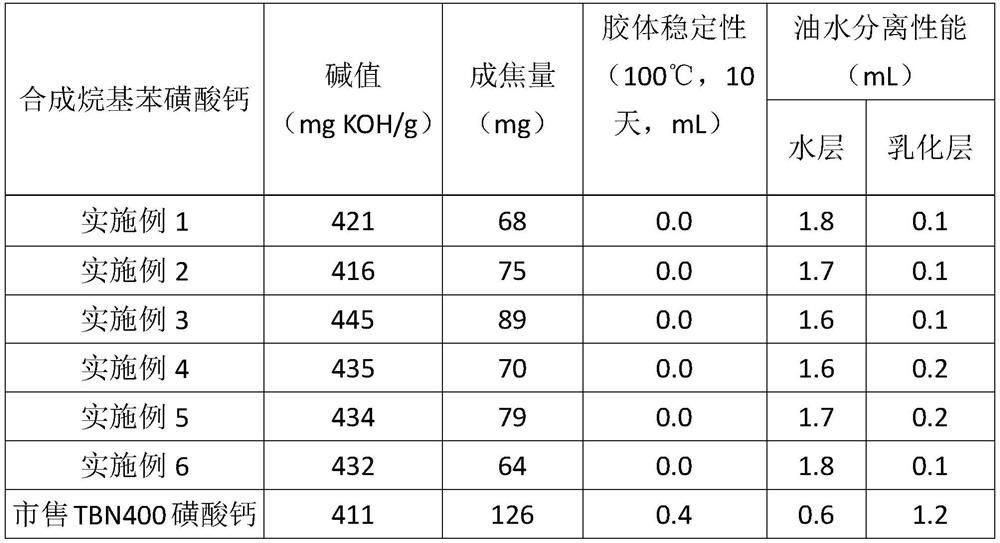

Examples

Embodiment 1

[0030] Add 100.0 g of MVI 150 dilution oil, 10.0 g of calcium hydroxide, and 80.0 g of C20-24 long-chain alkyl benzene sulfonic acid to a 500 mL four-neck reaction flask with an electric stirrer and a condensation dehydrator, start stirring and heat up to 35 -45 ℃, after stirring evenly, add 9.0 g of n-butanol as accelerator, 3.5 g of ionic solution auxiliary prepared by calcium chloride and acetic acid in a ratio of 1:2 (mass ratio), and neutralize the reaction at 70 ± 5 ℃ for 1.0 h, then the temperature was raised to 150±5°C, the butanol and the water generated by the reaction were removed from the system, and the calcium alkylbenzene sulfonate in the system formed stable micelle micelles; then the temperature was lowered to 45-55°C, and the reaction system was added with 45.0 g of calcium hydroxide, 10.0 g of calcium dodecyl phenate sulfide, 13.0 g of n-butanol as an accelerator, and 18.0 g of methanol as an accelerator. Carbon dioxide was introduced for high alkalinity reac...

Embodiment 2

[0033] Add 100.0 g of HVI 150 dilution oil, 15.0 g of calcium hydroxide, and 80.0 g of C20-24 long-chain alkyl benzene sulfonic acid to a 500 mL four-neck reaction flask with an electric stirrer and a condensation dehydrator, start stirring and heat up to 35 -45 ℃, after stirring evenly, add 9.0 g of n-butanol as accelerator, 3.0 g of ionic solution auxiliary prepared by calcium chloride and acetic acid in a ratio of 1:2 (mass ratio), and neutralize the reaction at 70 ± 5 ℃ for 1.0 h, then the temperature was raised to 150±5°C, the butanol and the water generated by the reaction were removed from the system, and the calcium alkylbenzene sulfonate in the system formed stable micelle micelles; then the temperature was lowered to 45-55°C, and the reaction system was added with 45.0 g of calcium hydroxide, 8.0 g of calcium dodecyl phenol sulfide, 13.0 g of n-butanol as an accelerator, and 18.0 g of methanol as an accelerator. Carbon dioxide was introduced for high alkalinity reacti...

Embodiment 3

[0036] Add 100.0 g of HVI 150 dilution oil, 10.0 g of calcium hydroxide, and 90.0 g of C20 long-chain alkyl benzene sulfonic acid to a 500 mL four-neck reaction flask with an electric stirrer and a condensation dehydrator, start stirring and heat up to 35-45 oz. ℃, after stirring evenly, add 9.0g of n-butanol as accelerator, 6.0g of ionic solution auxiliary agent prepared by calcium chloride and acetic acid in a ratio of 1:2 (mass ratio), neutralize at 70±5℃ for 1.0h, Then the temperature is raised to 150±5°C, the butanol and the water generated by the reaction are removed from the system, and the calcium alkylbenzene sulfonate in the system forms stable micelle micelles; Calcium 50.0g, sulfurized pentadecylphenate calcium 15.0g, accelerator n-butanol 15.0g, accelerator methanol 20.0g, start to pass carbon dioxide to carry out high alkalinization reaction, when the amount of carbon dioxide introduced reaches 13.0L, the second The remaining calcium hydroxide 50.0g was added for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com