Steel smelting gas desulfurization and sulfur recycling device system and method

A technology for iron and steel smelting and desulfurization equipment, applied in chemical instruments and methods, sulfur compounds, separation methods, etc., can solve the problems of undisclosed desulfurization operations, etc., achieve the effect of improving desulfurization efficiency, reducing the number of additions, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

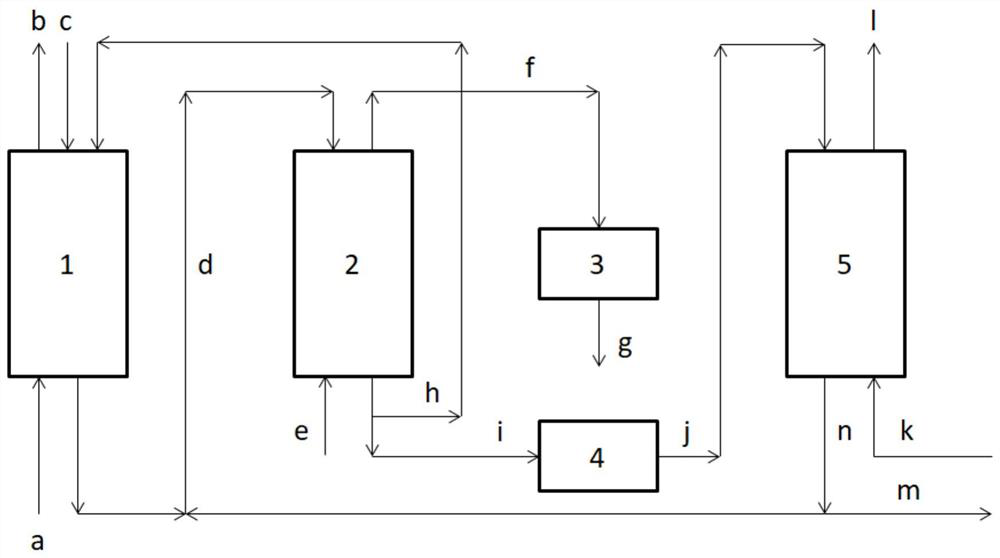

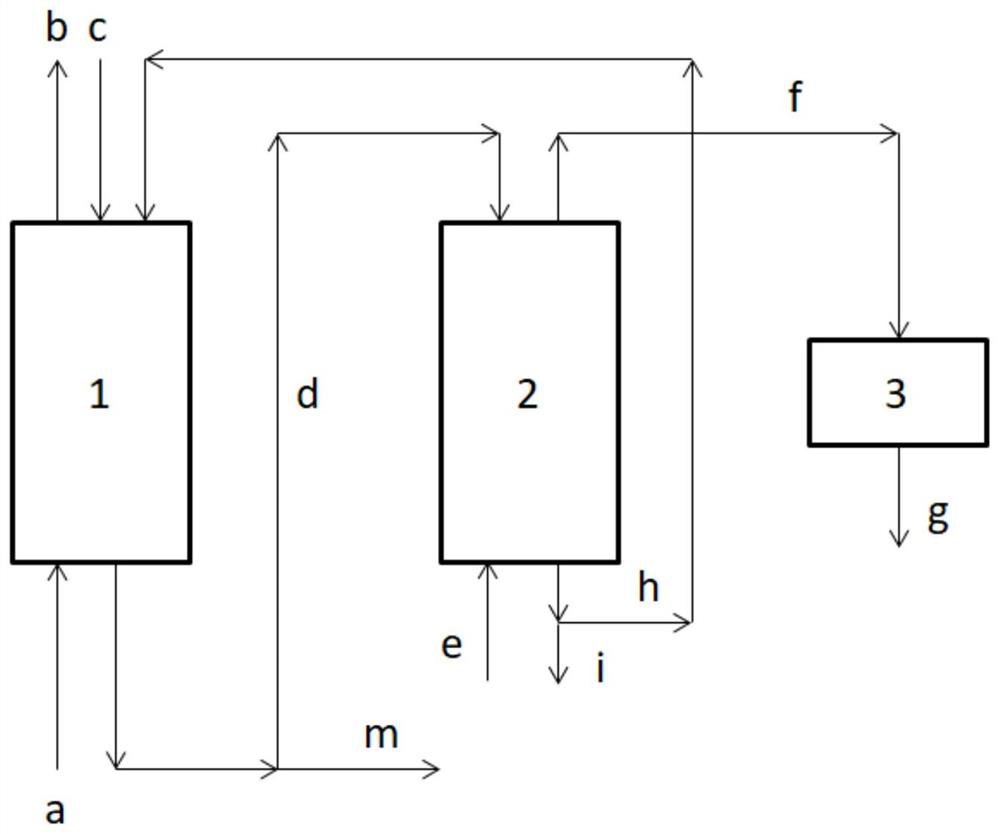

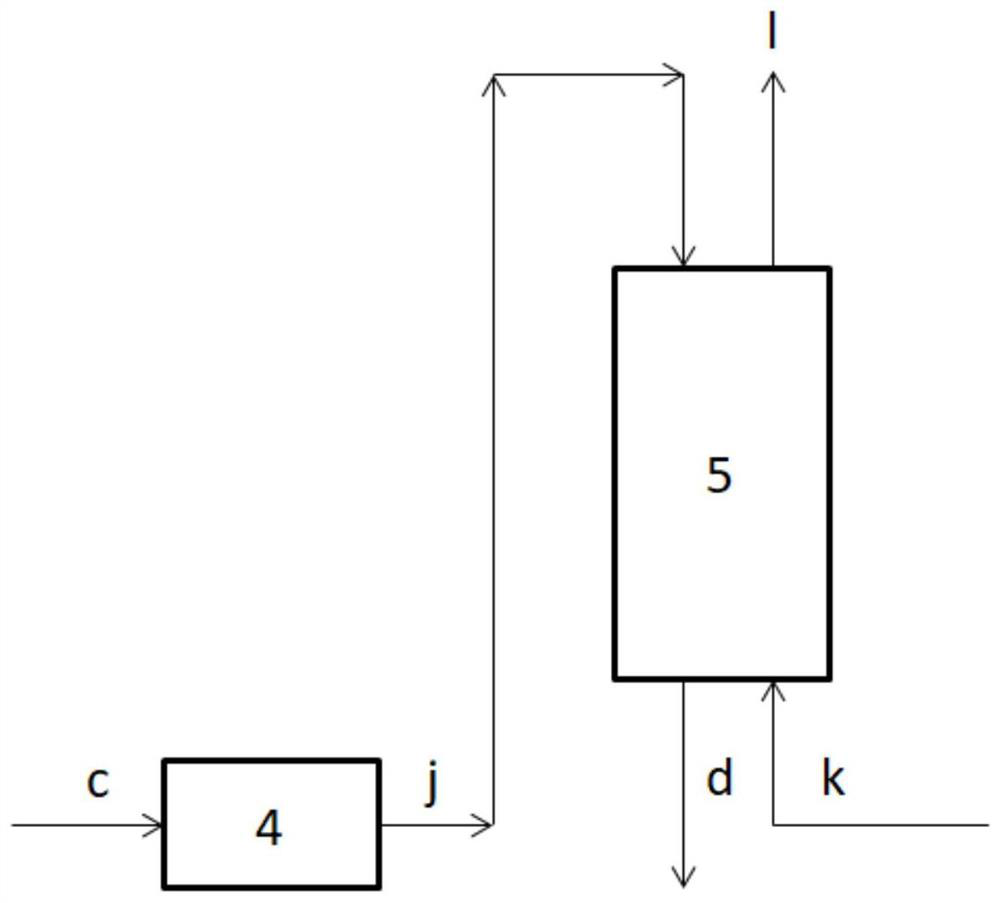

[0069] This embodiment provides a figure 1 The shown iron and steel smelting gas desulfurization and sulfur resource utilization device system, the iron and steel smelting gas desulfurization and sulfur resource utilization device system includes a desulfurization device 1 , a regeneration device 2 , an acid production device 3 , a modification device 4 and a hydrolysis device 5 .

[0070]The desulfurization device 1 described in this embodiment is provided with shaped activated carbon c for desulfurization; the regeneration device 2 is used to regenerate the deactivated shaped activated carbon c in the desulfurization device 1, and the sulfur-containing material f generated during regeneration enters the acid production device 3 , the sulfuric acid g is obtained by the acid plant 3; the regenerated fine particles h obtained by the regenerating device 2 are reused in the desulfurization device 1; the regenerated coarse particles i obtained by the regenerating device 2 enter the...

Embodiment 2

[0073] This embodiment provides a figure 1 The shown iron and steel smelting gas desulfurization and sulfur resource utilization device system, the iron and steel smelting gas desulfurization and sulfur resource utilization device system includes a desulfurization device 1 , a regeneration device 2 , an acid production device 3 , a modification device 4 and a hydrolysis device 5 .

[0074] The desulfurization device 1 described in this embodiment is provided with shaped activated carbon c for desulfurization; the regeneration device 2 is used to regenerate the deactivated shaped activated carbon c in the desulfurization device 1, and the sulfur-containing material f generated during regeneration enters the acid production device 3 , the sulfuric acid g is obtained by the acid plant 3; the regenerated fine particles h obtained by the regenerating device 2 are reused in the desulfurization device 1; the regenerated coarse particles i obtained by the regenerating device 2 enter th...

Embodiment 3

[0077] This embodiment provides a figure 1 The shown iron and steel smelting gas desulfurization and sulfur resource utilization device system, the iron and steel smelting gas desulfurization and sulfur resource utilization device system includes a desulfurization device 1 , a regeneration device 2 , an acid production device 3 , a modification device 4 and a hydrolysis device 5 .

[0078] The desulfurization device 1 described in this embodiment is provided with shaped activated carbon c for desulfurization; the regeneration device 2 is used to regenerate the deactivated shaped activated carbon c in the desulfurization device 1, and the sulfur-containing material f generated during regeneration enters the acid production device 3 , the sulfuric acid g is obtained by the acid plant 3; the regenerated fine particles h obtained by the regenerating device 2 are reused in the desulfurization device 1; the regenerated coarse particles i obtained by the regenerating device 2 enter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com