Rotary spraying construction method for improving ductility of pile foundation of operating subway station

A construction method and technology for subway stations, applied to foundation structure engineering, sheet pile walls, underground chambers, etc., can solve the problems of difficult compensation of bearing capacity and high risk, and achieve the effect of low investment cost, simple steps and convenient realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

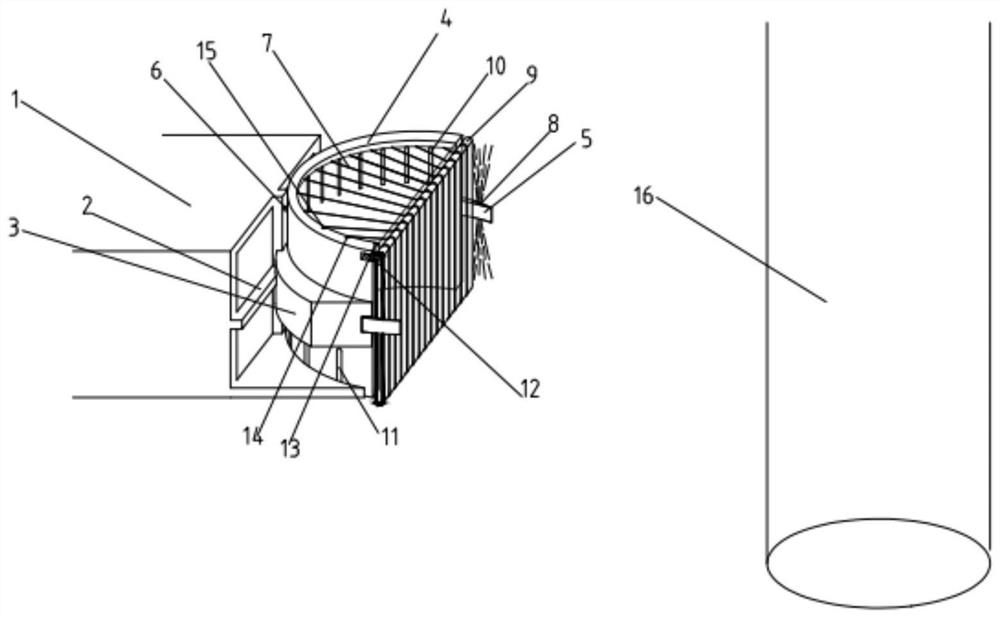

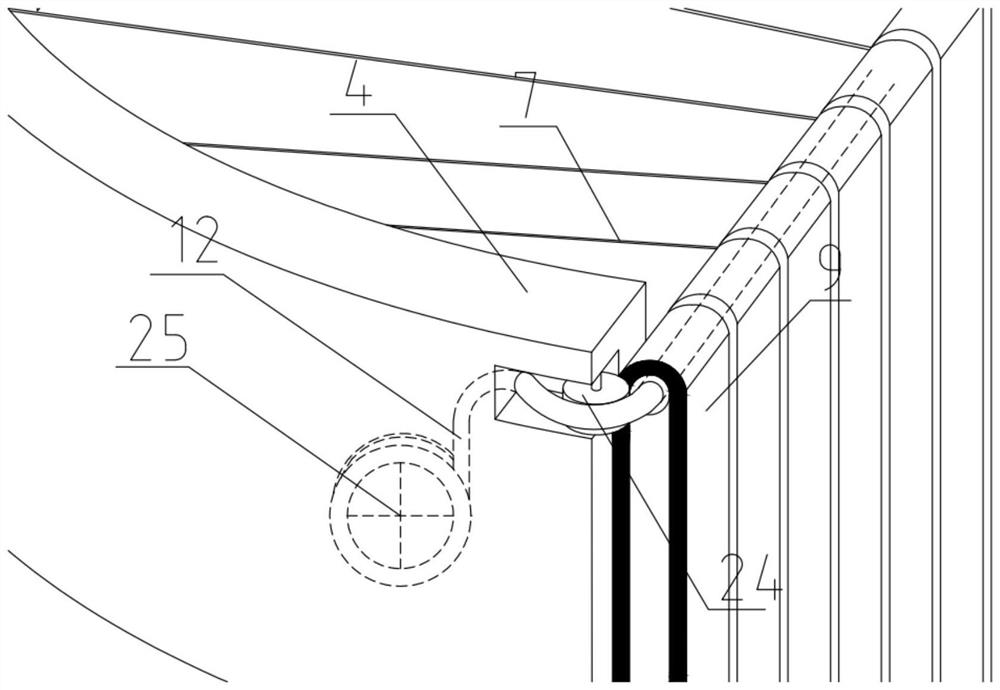

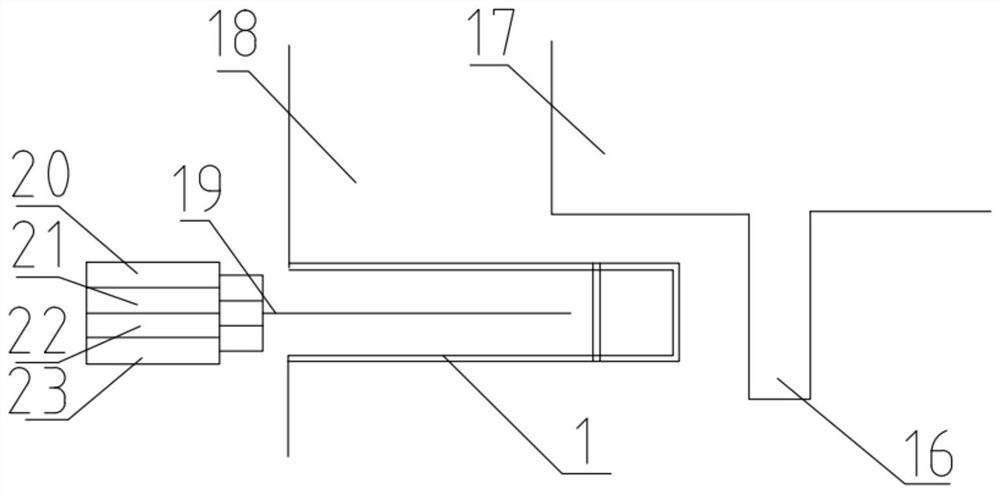

[0034] (1) Determine the height and size of the shield section. Determine the position and height where the shield machine will pass through the pile foundation, determine the construction hole circle on the side wall of the shield receiving shaft, and pre-embed the square steel pipe for the guide pipe in advance. In this example, the square steel pipe with a height of 18m and a side length of 0.25m.

[0035] (2) Set up equipment. The target pile foundation that needs to be reinforced is reinforced layer by layer. After the first layer of reinforcement position is determined, the rear supporting device is fixed in the shield receiving well, and the debugging work starts after the preparation of the front drill bit is completed.

[0036] (3) Excavation and excavation. After the equipment debugging is completed, the first section of excavation and cutting will start. Two adjacent cutting crawler belts 9 rotate in the opposite direction, and the soil body can be cut and brought...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com