Mechanical sealing interface fluid film forming measurement and control system

A technology of mechanical seal, measurement and control system, applied in the direction of engine seal, mechanical equipment, measuring device, etc., can solve the problem that the film formation state and thickness distribution of the interface fluid film cannot be adjusted in time, and the formation and integrity of the interface fluid film cannot be ensured. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

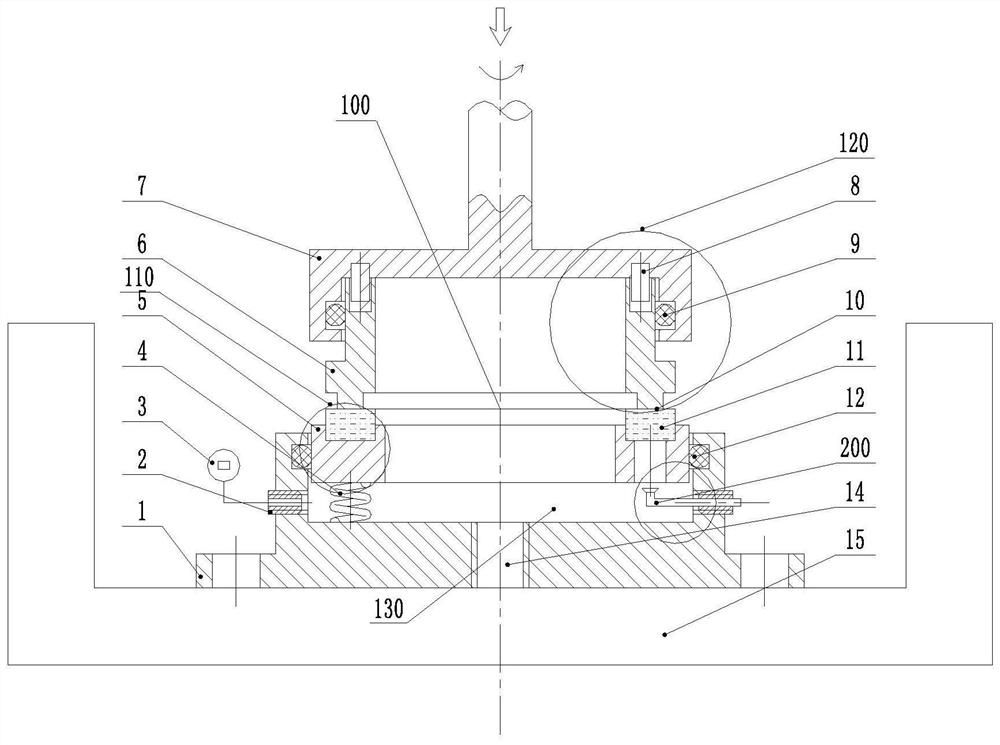

[0028] Embodiment 1 A mechanical seal interface fluid film forming measurement and control system, including a fluid container 15, a mechanical seal mechanism 100, and a liquid film forming measurement mechanism 200;

[0029] In the fluid container 15, a fluid lubricant containing nano-fluorescent powder is injected, and the top of the fluid container 15 is open, and a support 1 is fixed at the inner bottom; the top of the support 1 is provided with a sinking cavity, and the The bottom of the concave cavity is provided with a bottom threaded through hole 14; the side wall of the support 1 is provided with a plurality of support threaded holes 2a, and the support threaded holes 2a are arranged along the circumference of the support;

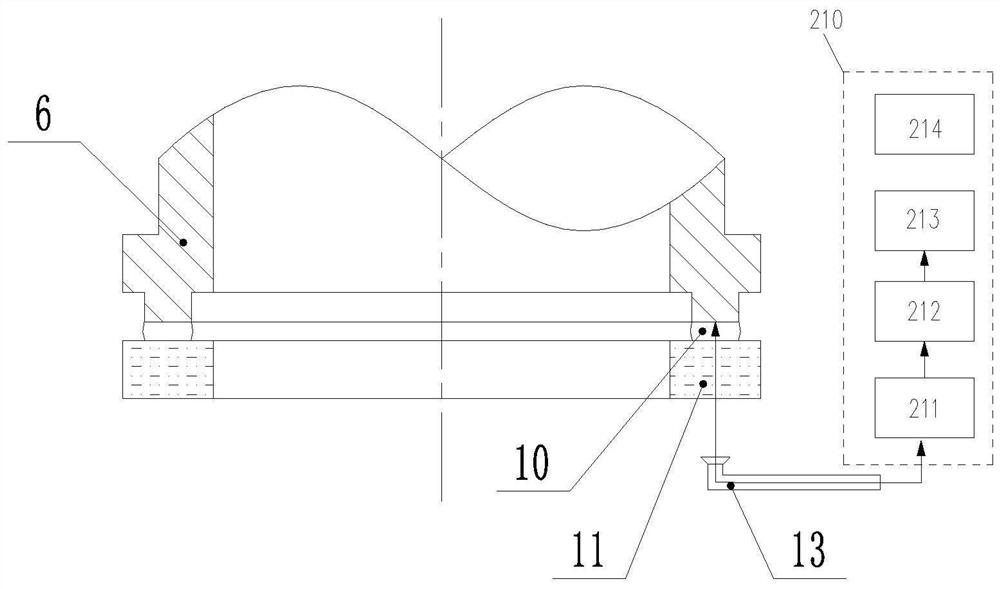

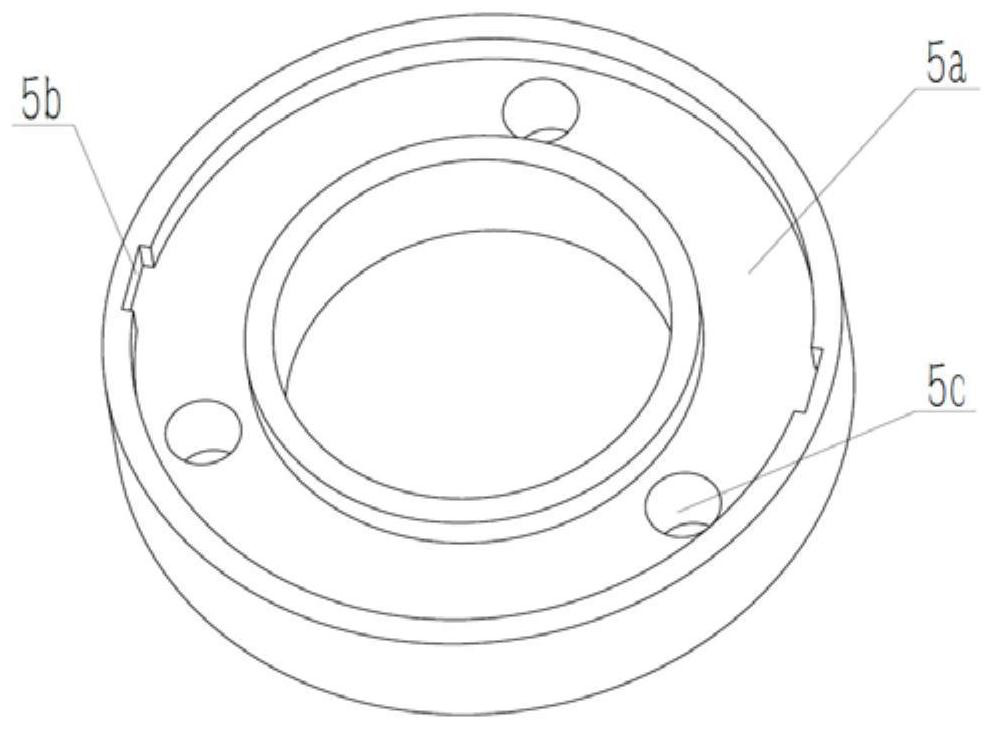

[0030] The mechanical seal mechanism 100 includes a matched static ring assembly 110 and a moving ring assembly 120. The static ring assembly 110 includes a static ring seat 5 and a static ring 11 installed in the static ring seat. The static ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com