Electromechanical coupling flywheel kinetic energy recovery device for traffic vehicle

A kinetic energy recovery, electromechanical coupling technology, applied in the field of transportation, to achieve the effect of reducing loss, meeting high-power applications, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

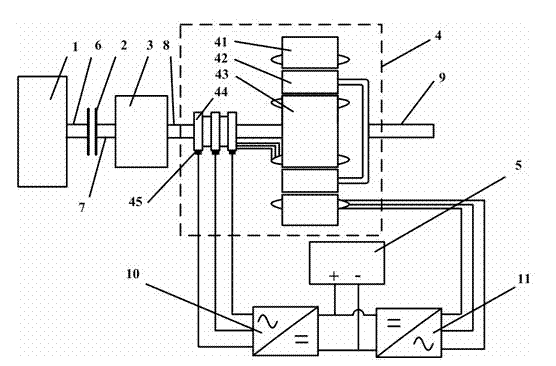

[0022] The present invention will be further described below in conjunction with the drawings.

[0023] by figure 1 It can be seen that an electromechanical coupling vehicle flywheel kinetic energy recovery device includes a flywheel 1, a clutch 2, a transmission 3, a dual-rotor motor 4, a traction inverter unit 11, a flywheel inverter unit 10, a traction rectifier unit 5, flywheel Axle 6, transmission high speed shaft 7 and load output shaft 9. The dual-rotor motor 4 includes transmission low speed shaft 8, slip ring 44, brush 45, inner rotor 43, outer rotor 42 surrounding said inner rotor 43, and surrounding The stator 41 of the outer rotor 42, the slip ring 44 is arranged on the transmission low-speed shaft 8, the brush 45 is in contact with the slip ring 44, and the stator 41 and the inner rotor 43 are both provided with polyphase windings; The flywheel 1 is connected to the clutch 2 through the flywheel shaft 6, the clutch 2 is connected to the transmission 3 through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com